04.01.2026 by Viktor Siebert

Repair of a Mitsubishi Servo Drive Unit MDS-B-V24-3535 with Alarm 32

Initial situation and fault description from the customer.

The Mitsubishi Servo Drive Unit MDS-B-V24-3535 was sent to us with the clear fault description that alarm 32 was permanently displayed on the front panel. For MDS-B servo drives, this alarm indicates a power module overcurrent error, meaning an overcurrent condition in the power stage or a failure of the transistor module.

The customer additionally reported that the servo motor had shown abnormal behavior some time before. There were sporadic axis faults, increased current consumption and unstable motion. As an initial measure, the motor was replaced by the customer because insulation measurements showed poor values. Despite replacing the motor, alarm 32 on the servo pack remained present, which ultimately led to the drive being sent to us for repair.

Initial inspection and safety measures

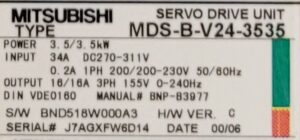

After the unit arrived at our workshop, a standardized incoming inspection was carried out. This includes documentation of the nameplate, checking for mechanical damage, unusual odors and visible signs of thermal stress.

Even during the external inspection, it became apparent that the unit had been subjected to significant thermal load. Slight discoloration around the heat sink and ventilation areas indicated prolonged operation under overload conditions. Before opening the unit, all safety procedures were strictly followed, including discharging the DC link capacitors and verifying that the unit was free of voltage.

Opening the unit and damage analysis

After opening the Mitsubishi MDS-B-V24-3535, the suspicion was confirmed very quickly. The power section showed severe damage. The installed transistor module was not only electrically defective but visibly destroyed. Individual channels showed clear burn marks, conductor paths were carbonized and surrounding components were thermally affected.

In such cases, it is evident that this is not a spontaneous single failure. An exploded transistor module almost always results from prolonged overload or from an external fault in the connected motor or cable system.

Relationship between motor failure and servo drive damage

Discussion with the customer provided a crucial clue. The previously installed servo motor had poor insulation values and was most likely contaminated by coolant or emulsion. In practice, we see this failure pattern very frequently. When emulsion penetrates the motor, insulation values gradually deteriorate. The motor draws increasingly higher currents, especially under load or during dynamic movements.

The servo drive attempts to compensate by delivering higher current. Over an extended period, this leads to massive thermal and electrical stress on the power stage. Alarm 32 often appears only when the transistor module has already suffered irreversible damage. Replacing the motor alone is no longer sufficient at that point, as the damage within the drive has already occurred.

Repair decision and scope of refurbishment

Based on the observed damage, it was clear that a simple partial repair would not be sufficient. In such cases, we consistently apply a preventive repair approach. The objective is not only to eliminate the current fault but to restore long term operational reliability of the unit.

The defective transistor module was completely removed. In addition, all adjacent assemblies were carefully inspected. This includes driver stages, current measurement circuits, protection circuits and thermally stressed solder joints. Components that had aged or were marginally stressed due to overheating were replaced preventively.

Preventive overhaul of the servo drive

In addition to replacing the power section, the entire unit underwent a preventive overhaul. This includes inspection of the DC link capacitors, verification of fan operation, cleaning of the heat sinks and checking all connectors.

Especially with MDS-B servo drives, proper cooling is essential for the longevity of the power electronics. Contaminated cooling channels or aged fans lead to localized heat accumulation, which can eventually result in exactly this type of failure.

All work was documented and carried out according to our internal quality standards.

Test procedures on our servo test bench

After completion of the repair, a full functional test was performed on our in house test bench. We operate specialized test equipment for Mitsubishi servo drives that allows simulation of realistic operating conditions.

The MDS-B-V24-3535 was powered up gradually. Initially, a no load test was performed while monitoring DC link voltage, current consumption and internal temperatures. This was followed by load tests, during which the behavior of the power stage under dynamic load conditions was evaluated.

Particular attention was paid to current symmetry, control stability and thermal behavior over an extended period. Only after successfully completing a continuous operation test was the unit approved for shipment.

Technical information on the Mitsubishi MDS-B-V24-3535

The Mitsubishi MDS-B-V24-3535 is a servo drive unit of the MDS-B series and is typically used in CNC machine tools. It is designed for power ratings of approximately 3.5 kW and operates with a DC link voltage of approximately 270 to 311 V DC. Control is handled via the corresponding Mitsubishi CNC system, and the unit incorporates extensive protective functions.

Alarm 32 power module overcurrent is one of the most critical alarms in this series, as it directly indicates a defect or severe overload within the power stage.

Preventive recommendations for operation

Clear recommendations can be derived from this repair case. Servo motors should be regularly checked for insulation resistance, especially in environments with coolant, emulsion or high humidity. Abnormal values should be taken seriously before consequential damage to the servo drive occurs.

Regular maintenance of the drives themselves is equally important. Cleaning, fan inspection and thermal monitoring can significantly extend service life and help prevent unplanned machine downtime.

Conclusion

The repair case of the Mitsubishi MDS-B-V24-3535 clearly demonstrates how closely motor condition and servo drive load are linked. A defective or contaminated motor can gradually destroy a servo drive without immediate visible symptoms. Through professional repair, preventive overhaul and realistic load testing, the unit was restored to reliable operation.

Such cases confirm our approach of not only repairing faults but analyzing root causes and delivering sustainable solutions.

To mentioned Mitsubishi Drive: Mitsubishi Servo Drive Unit MDS-B-V24-3535

More details about our Mitsubishi repair services can be found here:

Mitsubishi drive Repair by Industrypart

📞 Feel free to contact us with any questions about your Mitsubishi drive technology.

Our expert team is happy to help!

Technical specifications

| Parameter | Value |

|---|

| Manufacturer | Mitsubishi Electric |

| Device type | Servo Drive Unit |

| Model | MDS-B-V24-3535 |

| Series | MDS-B |

| Rated power | approx. 3.5 kW |

| Main circuit input voltage | DC 270 to 311 V |

| Control supply | 200 to 230 V AC, single phase |

| Motor output voltage | approx. 155 V AC, three phase |

| Output current | approx. 16 A |

| Cooling | Forced air cooling with internal fan |

| Protection class | Control cabinet installation |

| Display | 7 segment LED |

| Production date | 00/06 |

| Hardware version | C |

| Software version | BND518W000A3 |

| Manual reference | BNP-B3977 |

| Standard | DIN VDE 0160 |

Operating environment and typical applications

The Mitsubishi MDS-B-V24-3535 is used as a servo drive unit in CNC machine tools. Typical applications include feed axes in machining centers, lathes, grinding machines and special purpose machines. The unit operates in conjunction with Mitsubishi CNC controls and is designed for highly dynamic axis movements with precise control performance.

The operating environment is typically a control cabinet within an industrial machine. Critical environmental factors include elevated temperatures, coolant mist, emulsion, conductive dust and insufficient ventilation.

Functional description

The MDS-B-V24-3535 is responsible for complete power control of a servo motor. It converts the available DC link voltage into a controlled three phase motor output. Current, speed and position control loops ensure precise motor operation.

Integrated protective functions continuously monitor current, voltage, temperature, motor condition and communication with the CNC system. If limit values are exceeded, the unit immediately shuts down and displays a specific alarm code.

Alarms and troubleshooting

Selection of relevant alarms for the MDS-B series with focus on power stage and overload conditions

| Alarm code | Description | Cause | Corrective action |

|---|

| 32 | Power module error overcurrent | Overcurrent in transistor module | Check motor insulation, repair drive |

| 3A | Overcurrent | Excessive motor current | Reduce load, check parameters |

| 3B | Power module overheat | Power stage overheating | Check fan, cooling, environment |

| 33 | Overvoltage | DC link voltage too high | Check braking resistor and supply |

| 50 | Overload 1 | Continuous overload | Check mechanics and load profile |

| 51 | Overload 2 | High current over extended time | Verify motor and drive sizing |

| 45 | Fan stop | Cooling fan failure | Replace fan |

| 24 | Grounding | Motor or cable insulation fault | Check motor and cabling |

| 46 | Motor overheat | Motor or encoder overheating | Inspect motor condition |

| 60 to 77 | Power supply alarm | Power supply fault | Check power unit and supply |

Alarm 32 is particularly critical because it usually indicates existing damage in the power stage and cannot be cleared by reset or parameter adjustment.

Assemblies and components

| Assembly | Board designation | Function | Notes |

|---|

| Control board | RK112A-12 or BN634A980G51 | Control logic, communication, protection | Sensitive to overvoltage |

| Power board | RK122D-V24-3535 or BN638A019G51A | Power stage control | High thermal stress |

| Power module | Transistor module | Motor power generation | Critical under overload |

| Heat sink | integrated | Heat dissipation | Cleanliness essential |

| Fan | integrated | Forced cooling | Wear component |

Typical causes of power stage failures

Failure of the transistor module rarely occurs spontaneously. Common causes include continuously elevated motor currents, poor motor insulation due to emulsion or moisture, mechanical overload, contaminated cooling paths or incorrect motor to drive matching.

Gradual motor faults often cause the servo drive to operate outside its optimal range for extended periods until the power stage ultimately fails.

Service and maintenance recommendations

Regular insulation testing of servo motors is recommended, especially on machines operating with coolant. In addition, fans, heat sinks and control cabinet ventilation should be inspected and cleaned at regular intervals.

Preventive replacement of thermally stressed components in the servo drive can avoid unplanned downtime and significantly extend service life.