03.05.2025 by Viktor Siebert

Lost Time, Costly Mistakes – and Finally a Solution

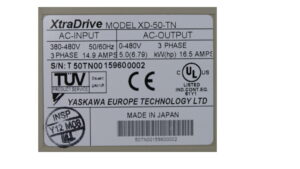

Repair of a Yaskawa XtraDrive XD-50-TN Servopack – A Real-World Case Study

The Case: Two Months of Downtime and No Results

A customer from the industrial printing sector approached us in desperation. Their production line had been down for two months due to a faulty Yaskawa XtraDrive XD-50-TN Servopack. Multiple inquiries to various service providers led to the same result: high costs and no solution.

The unit had already been sent out twice for inspection. Both service companies claimed they could test the device – but in reality, they lacked the necessary software, a compatible motor, or the correct connection cables. Despite performing no tests, significant charges were invoiced each time.

No Support from the Manufacturer

Even the manufacturer, Yaskawa, was unable to help. The device is no longer officially supported. The customer felt surrounded by empty promises – but no one could offer real assistance. As he put it:

“Why is this device so widely promoted online when apparently no one can test or repair it? I spent a lot of money, lost valuable time, and didn’t receive a single honest offer.”

Our Approach: If It Can’t Be Tested, It Can’t Be Trusted

Unfortunately, the customer found us only at the end of his long and frustrating journey. His skepticism was understandable – and justified. But we were able to convince him. We have been repairing XtraDrive units since 2017 and operate fully equipped test benches, including original cable sets, matching motors, and appropriate software.

We only received his go-ahead after providing a custom test video – because genuine confidence is built on verifiable facts, not vague promises.

Diagnosis: Error Code A.41 – DC Bus Undervoltage

The detected issue was error A.41 – an alarm indicating undervoltage in the DC bus. This is a type of fault that cannot be reliably identified without a full function test. During repair, we performed the following:

- Replacement of all defective and critical components (preventive overhaul)

- Intensive internal cleaning

- Parameter recovery and adjustment

- Load testing on our original test bench

- Complete documentation with checklists and measured values

One week later, the unit was fully operational again. The customer was finally able to resume production – greatly relieved.

Our Advice to Operators and Technicians

Do not rely on empty promises. Ask specific questions:

- Can the provider actually test the device under load?

- Are there images or videos of the actual test setup?

- Has the provider seen and solved this specific fault before?

- Is the testing and repair process fully documented?

A reliable repair partner proves themselves through equipment, experience, and transparency – not through marketing claims.

Conclusion

This case shows how quickly time and money can be lost when technical competence is lacking – and how important it is to choose a service provider who can genuinely test the device.

If you’re facing a similar situation – talk to us. We don’t just inspect – we deliver working solutions.

More Details, Price, and Delivery Time for:

Yaskawa XD-50-TN Servopack

Further details about our Yaskawa XtraDrive repair services can be found here.

📞 Feel free to contact us if you have any questions regarding your Yaskawa drive systems. Our experienced team is always happy to help.

Alarms and Fault Diagnostics

The XD-50-TN features an integrated diagnostic system that displays fault codes via LED. Common alarms include: Refer to our manual extract for specific error descriptions.

Technical Specifications

- Model: XD-50-TN

- Series: XtraDrive

- Input Voltage: 380–480 V (3-phase, 50/60 Hz, 14.9 AMPS)

- Output Voltage: 0–480 V (3-phase, 5.0 kW / 6.79 hp, 16.5 AMPS)

- Rated Power: 5.0 kW

- Compatible Motors: Sigma-II servo motors, e.g. SGMGH

- Control Modes: Position, speed, and torque control

- Interfaces: Standard digital I/O; optional Profibus DP

Special Features:

- NCT (Nonlinear Control Technology) for precise motion control

- OCA (Oscillation Cancelling Algorithm) for vibration suppression

- Automatic tuning for optimized servo performance

- Built-in encoder signal outputs and alarm displays