17.01.2026 by Viktor Siebert

Repair of a Yaskawa USAIKM-50-BK43-D AC Servo Motor with Encoder Damage Caused by Cooling System Leakage

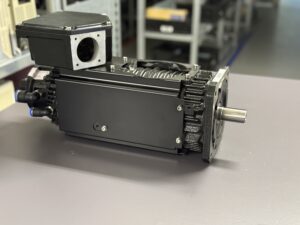

The Yaskawa AC servo motor type USAIKM-50-BK43-D was delivered to us with a fault pattern that we encounter very frequently with this motor series. The customer reported recurring encoder errors, unstable running behavior, and sporadic axis stoppages. These symptoms did not appear suddenly but developed gradually over an extended period.

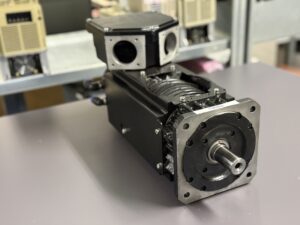

Already during the initial inspection, it became clear that this is a water-cooled high-performance servo motor designed for continuous operation at high speeds. The motor is equipped with an internal drainage system whose purpose is to discharge condensate and cooling fluid from the motor housing in a controlled manner. In practice, however, this system is highly dependent on cooling water quality and regular maintenance.

Condition at Arrival

After opening the motor, the suspected typical secondary damage was confirmed. The internal drainage system was heavily contaminated and almost completely blocked. Deposits and lime scale had caused the cooling fluid to no longer drain reliably. As a result, the fluid accumulated inside the motor housing and gradually reached the encoder area.

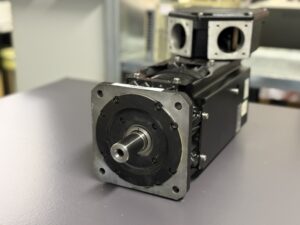

Clear signs of moisture, corrosion, and deposits were visible inside the encoder housing. The originally installed encoder with the designation UTMSI-10AAEAZR was electrically and mechanically damaged. Repair of the original encoder was no longer possible, as the internal sensor structures were irreversibly affected.

Root Cause Analysis

The root cause of the failure was not the encoder itself but clearly the motor’s cooling and drainage system. If this system is not cleaned over a long period, dirt particles and lime deposits accumulate. This issue occurs particularly often in applications using untreated cooling water or operating in harsh industrial environments.

When the drainage system becomes blocked, moisture slowly enters sensitive motor components. The encoder is not designed for such conditions. Even small amounts of moisture lead to signal errors, unstable feedback, and ultimately complete encoder failure.

Repair Process and Restoration

The motor was completely disassembled and subjected to thorough cleaning. All cooling channels and the drainage system were mechanically and chemically cleaned to remove deposits. This was followed by a detailed visual inspection of all sealing surfaces and sealing elements.

Since the original encoder could not be salvaged, a reengineered encoder type ERiP-UTMSI-10AA developed by us was installed. This encoder system is fully compatible with the original and was specifically designed for this motor type. It has been successfully used for many years in a large number of identical motors.

The bearings installed in the motor were also inspected. These are highly precise ceramic hybrid bearings designed for speeds of up to 16000 revolutions per minute. In this case, the bearings still showed clean running characteristics and were within acceptable tolerances, so replacement was not necessary.

Testing and Commissioning

After reassembly, the motor was resealed and tested on our test bench. The tests were carried out in combination with a Yaskawa inverter type CIMR-MXL2022. Speed behavior, current consumption, signal stability, and thermal performance were monitored over an extended period.

The motor reached its rated speeds without any issues and showed stable, clean encoder signals without dropouts or fault messages. Even during prolonged operation in the upper speed range, the system remained stable.

Evaluation and Practical Experience

This repair case clearly demonstrates that, for this motor type, the encoder is often not the primary cause of failure but rather a secondary damage resulting from insufficient maintenance of the cooling and drainage system. If this system is cleaned and monitored regularly, the motor can be operated reliably for many years.

More Info & Contact

To mentioned Yaskawa Motor: Yaskawa AC Servomotor USAIKM-50-BK43-D

mentioned Encoder: Yaskawa UTMSI-10AAEAZR ERiP-UTMSI-10AA

mentioned Inverter: Yaskawa Inverter vom Typ CIMR-MXL2022

More details about our Yaskawa repair services can be found here:

Yaskawa Motor Repair by Industrypart

📞 Feel free to contact us with any questions about your Yaskawa drive technology.

Our expert team is happy to help!

Technical Specifications

| Parameter | Value |

|---|

| Motor type | Yaskawa USAIKM-50-BK43-D |

| Motor design | AC servo motor |

| Rated power | 7.3 kW |

| Rated torque | approx. 13.9 Nm |

| Rated voltage | 200 V |

| Rated current | 80 A |

| Maximum speed | 16000 min⁻¹ |

| Cooling type | Water cooling |

| Bearing type | Ceramic hybrid bearings |

| Original encoder | UTMSI-10AAEAZR |

| Replacement encoder | ERiP-UTMSI-10AA |

| Manufacturer | Yaskawa Electric |

| Country of origin | Japan |

Operating Environment and Compatible Equipment

The Yaskawa USAIKM-50-BK43-D is typically used in highly dynamic machines where high speeds, precise control, and continuous thermal load are required. These include machine tools, machining centers, and special-purpose machines with continuous operation.

The motor is operated, among others, in combination with the following inverter:

Yaskawa inverter CIMR-MXL2022

This motor type is particularly common in applications with long operating times at high speeds, making reliable cooling absolutely essential.

Functional Description

The motor is designed as a water-cooled high-performance AC servo motor. Speed control is achieved via a high-resolution incremental encoder. Position and speed feedback are essential for stable operation. The internal drainage system ensures controlled removal of condensate and cooling fluid. If this system becomes blocked, the previously described consequential damage occurs.

Alarm Messages and Troubleshooting

| Code | Fault description | Cause | Corrective action |

|---|

| 01 | Overcurrent | Short circuit or overload | Check motor cables |

| 02 | Overvoltage | DC bus overvoltage | Check supply voltage |

| 03 | Undervoltage | Supply voltage too low | Check power supply |

| 05 | Overheat | Insufficient cooling | Check cooling circuit |

| 07 | Control power fault | Unstable control voltage | Check power supply |

| 09 | Ground fault | Ground short | Measure insulation |

| 11 | Motor overload | Continuous overload | Reduce load |

| 13 | Output phase loss | Phase failure | Check power stage |

| 20 | Motor overcurrent | Overcurrent in U V W phases | Check cooling and motor |

| 22 | Thermistor fault | Temperature sensor failure | Check sensor |

Components

| Assembly | Description | Function |

|---|

| Motor housing | Water-cooled housing | Heat dissipation |

| Drainage system | Internal discharge path | Fluid removal |

| Encoder | Incremental encoder | Speed and position feedback |

| Bearings | Ceramic hybrid bearings | High-speed operation |

| Seals | Multi-stage sealing system | Moisture protection |

Preventive Measures for the Customer

Regular cleaning of the cooling and drainage system is essential. Cooling water should be filtered and checked for deposits. In addition, periodic inspection of encoder signals and sealing elements is recommended. These measures significantly extend the service life of the motor and help avoid unplanned downtime.

Conclusion

The Yaskawa USAIKM-50-BK43-D is a highly precise and powerful servo motor. Its long-term reliability depends largely on proper maintenance of the cooling system. Through targeted preventive measures and the use of reengineered encoder solutions, even typical weak points can be permanently controlled.