17.08.2025 by Viktor Siebert

When an Encoder Causes Intermittent Failures. Lessons from the SGMSH-20DCA6F-OY

In many production environments, the Yaskawa SGMSH-20DCA6F-OY motor is a reliable workhorse. Yet one particular weak spot emerges frequently in our repair work: the encoder.

A typical scenario begins with the drive often an SGDH-20DE – showing alarm A.81 (Absolute Encoder Backup Error). The problem rarely starts suddenly. Instead, it creeps in over time. Operators might notice the machine occasionally crashing without an obvious reason, or the drive showing the error sporadically.

A restart seems to resolve the issue, for a while. Then it returns. This intermittent nature is what makes diagnosis so frustrating. The question quickly becomes: is the drive faulty, is it the motor, or are the cables to blame? Many customers report long troubleshooting phases and, at times, genuine despair.

Because the error is displayed on the drive, suspicion often falls there first. In some cases, customers replace the drive, and initially, there’s a period of calm – only for the fault to reappear weeks or months later. Environmental factors such as temperature changes, humidity, and vibrations can influence the timing and severity of the failure.

When an encoder begins to degrade, these external influences can become the final trigger, causing the fault seemingly at random.

Our Repair Measures

When we receive a motor with this fault, the repair process is systematic:

- Comprehensive disassembly and inspection to identify both obvious and hidden defects.

- Preventive component replacement, even if no visible damage is present:

- Bearings (to ensure smooth rotation and minimize vibration impact on the encoder)

- Connectors (to eliminate contact resistance and intermittent signal loss)

- Seals and gaskets (to protect against moisture and dust ingress)

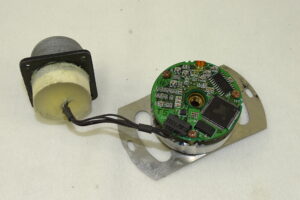

- Encoder replacement: the original UTSIH-B17CK unit can be swapped for a new one, programmed, and precisely adjusted.

- Thorough cleaning using a specialized cleaning emulsion to remove oil residues, dust, and conductive particles.

- Controlled drying in a dedicated oven to eliminate residual moisture.

Testing Procedure

After reassembly, the motor is tested on a dedicated test bench. The test process follows a detailed checklist:

- Functional testing under various load conditions

- Encoder signal quality measurement

- Thermal behavior analysis during prolonged operation

- Verification of speed and position accuracy

Only once all parameters meet the required specifications is the motor cleared for return to service.

Preventive Tips for Operators

While no motor is immune to wear, certain practices can reduce the likelihood of encoder-related downtime:

- Keep the motor environment as dry as possible to limit moisture ingress.

- Avoid exposing the motor to sudden temperature shifts that can cause condensation.

- Check and maintain cable integrity, especially shielded encoder cables.

- Monitor for unusual vibrations, which can shorten encoder and bearing life.

- Schedule periodic inspections, even if no fault is currently present, to catch early signs of degradation.

By addressing these areas proactively, operators can extend the life of both motor and drive and avoid the costly, frustrating cycle of intermittent faults.

Why does the encoder fail? (Useful to know)

The encoder is the “eye” of the motor, it provides the feedback signals for position, speed, and torque. Without it, the drive has no way of knowing the shaft’s exact position. Yet this sensitive component is exposed to tough conditions in industrial environments.

Temperature changes: When the motor runs in environments with strong fluctuations, condensation can form inside. Moisture penetrates the encoder and attacks the electronics.

Vibrations: Rough running, worn bearings, or machine oscillations transfer directly to the encoder. Over time, microcracks or signal disturbances develop in the electronics.

Moisture and oil mist: In many machine tools, a mix of coolant, oil, and high humidity is present. If this enters the encoder through worn seals, contacts or circuit paths corrode.

Aging of electronics: Even without external factors, components like optical sensors or capacitors inside the encoder age. The signal becomes weaker and sporadic failures occur.

Cables and connectors: Often, the issue is not only with the encoder itself, but with the connections. Corrosion, loose contacts, or broken wires cause signal loss, which then appears as encoder errors.

The path to failure is usually gradual:

At first, short signal disturbances appear, the machine “hiccups” or occasionally crashes. Then the drive shows error A.81, which disappears again after a restart. Eventually, the error becomes more frequent until the encoder finally stops delivering usable signals.

Information about the mentioned Servopack and Servomotor:

More information about our Yaskawa repairs can be found here.

📞 Feel free to contact us if you have any questions regarding your Yaskawa drive technology. Our experienced team is always ready to assist you.

Device Data (Technical Specifications)

| Parameter | Value |

|---|

| Model | SGMSH-20DCA6F-OY |

| Series | Yaskawa Sigma II |

| Rated Power | 2000 W |

| Rated Torque | 6.36 Nm |

| Rated Speed | 3000 min⁻¹ |

| Rated Current | 6.2 A |

| Rated Voltage | 400 V AC |

| Insulation Class | F |

| Shaft Type | Straight shaft with key and tap (Code 6) |

| Encoder | 17-bit absolute/incremental encoder (Code C) |

| Protection Class | IP67 (with oil seal) depending on version |

| Manufacturing Date | 06/2015 |

| Country of Origin | Japan |

Operating Environment & Compatible Equipment

The SGMSH-20DCA6F-OY operates in CNC machines, industrial robots, machine tools, and automation lines.

It is designed for use with Yaskawa Sigma II servo amplifiers (e.g., SGDH series) and is used in high-precision, high-torque axis drives.

Recommended environment:

- Ambient temperature: 0 – 40 °C

- Humidity: 20 – 80% (non-condensing)

- Protection against direct sunlight, oil mist, and conductive dust

Functional Description

The SGMSH-20DCA6F-OY is a compact, high-speed AC servo motor with a 17-bit encoder that enables precise position, speed, and torque control.

Features include:

- High torque density in a small size

- Rapid acceleration and deceleration

- Accurate position feedback to the servo amplifier

- Compatibility with both absolute and incremental operation

- Robust design for harsh industrial environments

Alarm Messages & Troubleshooting

| Alarm Code | Alarm Name | Description | Solution |

|---|

| A.02 | Parameter Breakdown | Servo amplifier EEPROM data abnormal | Check parameters, reinitialize if necessary |

| A.03 | Main Circuit Encoder Error | Power circuit detection error | Check wiring, replace amplifier if needed |

| A.05 | Servomotor/Amplifier Combination Error | Mismatched motor/amplifier capacities | Use compatible motor/amplifier combination |

| A.10 | Overcurrent / Heat Sink Overheated | Overcurrent or amplifier heat sink overheated | Reduce load, check cooling |

| A.30 | Regeneration Error Detected | Fault in regenerative circuit | Inspect resistor/circuit |

| A.32 | Regenerative Overload | Energy exceeds resistor capacity | Adjust braking resistor |

| A.40 | Overvoltage | DC voltage too high | Check mains supply |

| A.41 | Undervoltage | DC voltage too low | Check power supply |

| A.51 | Overspeed | Excessive motor speed | Verify parameters |

| A.71 | Overload: High Load | Continuous overload condition | Reduce load, consider larger motor |

| A.81 | Absolute Encoder Backup Error | Encoder power supply failed | Check battery/power supply |

| A.C9 | Encoder Communication Error | No communication with encoder | Inspect cables, connectors, encoder |

Components

| Component | Description |

|---|

| Stator | Windings for torque generation |

| Rotor | Permanent magnet rotor |

| Encoder UTSIH-B17CK | 17-bit absolute/incremental feedback device |

| Shaft Bearings | High-precision ball bearings |

| Housing | Black-coated aluminum die-cast |

| Shaft End | Straight shaft with key and tap |

| Connection Terminals | Separate power and signal wiring |

| Cooling System | Passive cooling via housing surface |

| Shaft Seal | Oil and dust protection (IP67 option) |