13.02.2026 by Viktor Siebert

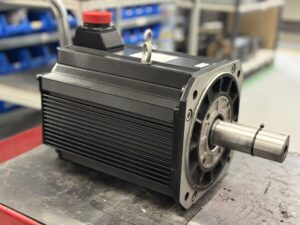

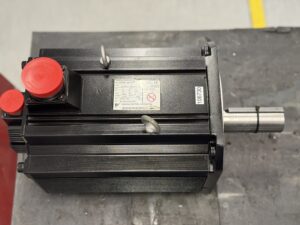

Repair of a Yaskawa SGMGH-1ADCA6F-OY Servo Motor with Severe Moisture Damage and Encoder Failure

The motor was delivered with recurring encoder alarms A.70 and A.73 on the SGDH drive. Additionally, insulation measurements were unstable and sometimes below specification.

During initial inspection, coolant contamination was clearly visible at the shaft area. The shaft seal had hardened and lost its elasticity, allowing coolant to enter the motor interior.

After disassembly the following damage was identified:

- Severe corrosion on both motor bearings

- Coolant contamination inside stator housing

- Reduced insulation resistance

- Completely destroyed UTSIH-B17CK encoder

Insulation measurement showed values below 1 megaohm, making immediate refurbishment necessary.

Detailed Repair Process

The motor was fully dismantled.

- Chemical cleaning of the stator

- Controlled oven drying process

- Insulation test after drying

- Replacement of both bearings

- Replacement of all sealing elements

- Installation of a new UTSIH-B17CK encoder

- Precise encoder alignment

- Exact programming to match the motor specifications

Special attention was given to preventive sealing improvements.

A high-quality industrial shaft seal was installed. Cable glands were resealed to prevent future ingress of coolant.

Test Bench Procedure

After assembly, the motor underwent full load testing:

- 400 V supply simulation

- 8 hour continuous operation

- Thermal load up to 80 percent rated torque

- Encoder signal monitoring

- Final insulation measurement

Result:

- Stable operation

- Precise encoder feedback

- No abnormal current peaks

- Insulation fully restored

The motor was returned to the customer fully operational and parameter matched to the SGDH Sigma II drive.

Preventive Measures for the Customer

To extend service life:

- Inspect shaft seal annually

- Replace shaft seal every 2 to 3 years

- Perform yearly insulation measurement

- Check cable glands regularly

- Clean cooling channels

- Avoid direct coolant spray on motor shaft

- Replace cooling fans periodically

Moisture is the most common cause of encoder destruction in industrial servo motors.

Conclusion

The SGMGH-1ADCA6F-OY is a robust 11 kW servo motor.

The weak point is mechanical sealing, not electrical design.

Preventive maintenance significantly reduces downtime and repair costs.

Information about the mentioned Servopack and Servomotor:

More information about our Yaskawa repairs can be found here.

📞 Feel free to contact us if you have any questions regarding your Yaskawa drive technology. Our experienced team is always ready to assist you.

Technical Specifications

| Field | Value |

|---|

| Type | SGMGH-1ADCA6F-OY |

| Manufacturer | Yaskawa Electric Corporation |

| Power | 11 kW |

| Rated Torque | approx. 70 Nm |

| Rated Speed | 1500 rpm |

| Rated Voltage | 400 V |

| Rated Current | approx. 28 A |

| Encoder | UTSIH-B17CK |

| Encoder Type | Incremental 17 Bit |

| Insulation Class | F |

| Cooling | Self ventilated |

| Protection Class | approx. IP65 |

| Compatible Drive | SGDH Servopack Sigma II |

| Manual Reference | Yaskawa M/F/S/D Series |

Application Environment and Compatible Equipment

The SGMGH-1ADCA6F-OY servo motor is typically used in:

- CNC machining centers

- Milling machines

- Grinding machines

- Automated production systems

It is operated together with a Yaskawa SGDH Servopack from the Sigma II series.

Typical combinations:

- Yaskawa SGDH Sigma II servo drive

- Siemens or Fanuc controlled CNC systems

- Retrofit systems in heavy machining

The 17-bit incremental encoder UTSIH-B17CK ensures high-resolution position and speed feedback for precise closed-loop control.

Functional Description

The SGMGH servo motor is a permanent magnet synchronous motor designed for dynamic torque control.

System structure:

- Three-phase 400 V input

- Current control inside the SGDH drive

- Speed and position closed loop control

- Encoder feedback via UTSIH-B17CK

- PWM inverter output stage

The SGDH drive continuously monitors:

- Motor current

- DC bus voltage

- Encoder feedback integrity

- Motor temperature

- Heatsink temperature

If any parameter exceeds its safety limits, the drive immediately shuts down and displays an A.xx alarm code.

Alarm Messages and Troubleshooting SGDH Sigma II

Correct Sigma II alarm codes:

| Code | Error Description | Typical Cause | Corrective Action |

|---|

| A.10 | Overcurrent | Short circuit in motor winding or cable | Check motor and wiring |

| A.30 | Regeneration Error | Regenerative resistor overload | Inspect braking resistor |

| A.40 | Overvoltage | Excessive DC bus voltage | Check supply voltage |

| A.41 | Undervoltage | Low input voltage | Check mains supply |

| A.50 | Overspeed | Speed exceeded limit | Check parameters |

| A.70 | Encoder Error | Encoder hardware failure | Replace encoder |

| A.71 | Encoder Communication Error | Broken encoder cable | Inspect cable |

| A.72 | Encoder Battery Warning | Low battery in absolute encoder | Replace battery |

| A.73 | Encoder Signal Error | Noise or moisture contamination | Clean or replace encoder |

| A.80 | Motor Overtemperature | Thermal overload | Reduce load |

| A.81 | Heatsink Overtemperature | Cooling failure | Inspect fan |

| A.90 | Overload | Continuous overload above rating | Reduce load |

| A.C1 | CPU Error | Internal control fault | Replace drive |