02.01.2026 by Viktor Siebert

Repair of a Yaskawa SGD-02AN Servopack with Mechatrolink-I Communication Failure

Initial Situation and Fault Description.

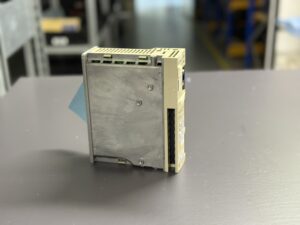

This repair case concerns a Yaskawa SGD-02AN servopack used in an industrial CNC application.

The unit could still be powered on at the customer site, showed no classic power-related faults and no immediate overcurrent or voltage alarms. However, one essential function was no longer available: stable communication via Mechatrolink-I with the PC.

The customer had already carried out extensive troubleshooting. Several PCs with different Mechatrolink-I interface cards, various cables and different software configurations were tested. The behavior remained unchanged: the servopack was not accessible, and parameters could neither be read nor written.

This combination of apparently normal basic operation together with a complete communication failure typically indicates a deeper defect within the internal communication or control electronics.

Findings After Opening the Unit

After the unit arrived at our workshop, a visual and electrical incoming inspection was performed.

Immediately after opening the housing, a clear damage pattern became visible.

On the internal communication board, severe electrolyte leakage from several capacitors was detected. The leaked electrolyte had not only spread on the surface but had penetrated deep into the multilayer PCB. In several areas, traces were corroded, vias were damaged, and solder joints were chemically attacked.

Such damage is particularly critical because it often develops gradually. Even if individual components still appear electrically measurable, long-term reliability can no longer be guaranteed. In this case, it was clearly evident that a sustainable repair of the affected board was technically impossible. Local cleaning or partial repair would not have provided a reliable solution.

Technical Decision and Repair Strategy

Based on these findings, the decision was made to completely replace the damaged communication board.

Thanks to our stock, we were able to rely on tested spare boards as well as complete SGD-02AN units that could be used as donors.

The replacement board was mechanically and electrically adapted and then integrated into the servopack. A particularly critical aspect with this device generation is the correct transfer of parameters and device settings, as these are closely linked to the specific machine configuration.

Fortunately, the relevant parameters could be secured from the customer system and transferred to the repaired servopack. After that, a complete initialization and a series of communication tests via Mechatrolink-I were performed.

Functional Test and Final Inspection

After replacing the board, the servopack was put into operation on our test bench.

Communication via Mechatrolink-I was immediately stable. Parameter access, status feedback and cyclic communication functioned without any issues.

In addition, the following tests were carried out:

- Long-term test at nominal voltage

- Monitoring of internal supply voltages

- Temperature behavior under continuous operation

- Verification of digital inputs and outputs

- Check of control stability in simulated operation

After completing all tests, the unit was released without restrictions.

The servopack has since been operating reliably in the customer system, and the customer was fully satisfied with the solution.

Practical Conclusion

This repair case clearly demonstrates that electrolyte damage to PCBs is one of the most critical aging-related issues in servopacks. It is particularly insidious because such damage does not always cause an immediate total failure but often initially manifests itself as communication problems or sporadic malfunctions.

In many cases, an early replacement of affected assemblies is more economical than attempting partial repairs. This requires experience, access to suitable spare parts and clean parameter handling.

Information about the mentioned Servopack: Yaskawa SGD-02AN Servopack

For more details about our Yaskawa repair services, visit: Yaskawa Repairs

📞 Feel free to contact us if you have any questions about your Yaskawa drive technology!

Technical Information Yaskawa SGD-02AN Servopack

Device Overview

| Parameter | Value |

|---|

| Manufacturer | Yaskawa Electric Corporation |

| Model | SGD-02AN |

| Device Type | AC Servo Drive |

| Series | Sigma I |

| Communication Interface | Mechatrolink-I |

| Axes | 1 axis |

Electrical Data

| Parameter | Value |

|---|

| Input Voltage | AC 200–230 V |

| Phases | Single-phase |

| Line Frequency | 50 / 60 Hz |

| Input Current | approx. 4.0 A |

| Output Voltage | AC 0–230 V |

| Output Current | approx. 2.0 A |

| Rated Power | approx. 200 W |

| Motor Frequency Range | 0–300 Hz |

Mechanical and Environmental Data

| Parameter | Value |

|---|

| Cooling | Convection cooling |

| Mounting | Control cabinet |

| Operating Temperature | 0 to 55 °C |

| Certification | UL Listed |

| Country of Origin | Japan |

Typical Applications

- CNC machines

- Positioning axes

- Automation systems

- Packaging machines

- Special-purpose machinery with Mechatrolink-I control

Typical Failure Causes for This Series

- Electrolyte leakage from aged capacitors

- Corrosion on communication boards

- Unstable Mechatrolink connections

- Deviations in internal control voltages

- Long-term thermal stress

Practical Recommendation

For devices of this generation, we recommend preventive inspection of the internal electronics, especially the capacitors in the control and communication sections. Early detection can prevent total failure and significantly extend service life.

Alarm Table Yaskawa SGD-02AN Servopack (Sigma I Series)

Overview of Typical Alarm Codes and Causes

| Alarm Code | Alarm Name | Description | Typical Cause | Corrective Action |

|---|

| A.00 | Absolute data error | Error in absolute encoder data | Encoder supply missing, incorrect wiring, defective encoder or control board | Check encoder and wiring, replace motor or servopack if required |

| A.02 | User constants breakdown | Parameters corrupted or invalid | Power interruption during parameter write, memory failure | Replace servopack |

| A.04 | User constant setting error | Invalid parameter setting | Parameter outside allowable range | Reload or correct parameters |

| A.10 | Overcurrent | Overcurrent detected in power circuit | Short circuit, motor fault, defective power stage or control board | Check motor and wiring, replace servopack |

| A.31 | Position error pulse overflow | Excessive position deviation | Incorrect tuning, mechanical overload, encoder issues | Check tuning parameters and mechanics |

| A.40 | Overvoltage | DC bus voltage too high | Regenerative energy too high, incorrect supply voltage, defective board | Check supply voltage, replace servopack |

| A.51 | Overspeed | Maximum speed exceeded | Encoder malfunction, incorrect parameters | Check encoder and parameters |

| A.70 | Overload | Overload detected | Excessive mechanical load, encoder or board fault | Reduce load, check motor or servopack |

| A.80 | Absolute encoder error | Absolute encoder fault | Encoder defect or communication failure | Check encoder or replace motor |

| A.81 | Absolute encoder backup error | Backup power error | Battery depleted, internal capacitor failure | Replace battery, check servopack |

| A.82 | Absolute encoder sum-check error | Checksum error in encoder data | Corrupted encoder data | Replace encoder or motor |

| A.83 | Battery error | Battery voltage too low | Depleted encoder battery | Replace battery |

| A.84 | Absolute encoder data error | Invalid encoder data | Encoder communication disturbed | Check encoder or servopack |

| A.F3 | Power loss error | Power interruption detected | Line voltage interruption or drop | Check power supply |

| CPF00 | Digital operator transmission error 1 | Operator communication error | Cable fault, noise, defective operator | Check cable, replace operator |

| CPF01 | Digital operator transmission error 2 | Communication error during operation | EMC interference, hardware fault | Check wiring and grounding |