18.01.2026 by Viktor Siebert

Repair of a Yaskawa Servopack SGDH-08AE-SY202 with Alarm A.71

Initial condition and reported fault.

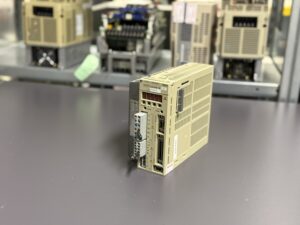

The Yaskawa Servopack SGDH-08AE-SY202 Ver. 0F214-0 was delivered with the reported alarm A.71. According to the customer, the fault occurred intermittently, mainly during power-up or shortly after the READY signal was activated. In several cases the axis could not be enabled and the machine failed to start. No clear correlation to mechanical overload or operator action could be identified.

Alarm A.71 on Yaskawa Sigma II servopacks indicates a momentary interruption or instability of the internal power supply. In practice this alarm is critical because it is often sporadic and can be caused by both external influences and internal aging effects.

Condition of the unit upon arrival

Visual inspection showed a mechanically intact unit without visible damage. However, age-related contamination was found on the fan, heatsink and inside the housing. Fine dust deposits were visible in the power and supply sections. No signs of previous repairs or non original modifications were detected.

This condition is typical for Sigma II servopacks that have been in continuous operation for many years. Even if they appear functional externally, internal components are often already affected by aging.

Diagnosis and root cause analysis

After cleaning and preparation, the servopack was tested on our dedicated Sigma II test bench. The A.71 alarm could be reproduced by repeated power cycling. During start-up, the internal supply voltages were not always built up in a stable manner. Short voltage drops were detected which immediately triggered the alarm.

Measurements showed that the auxiliary power supplies were no longer fully stable within their nominal ranges, especially when the unit was cold or after longer downtime. This behavior is characteristic of aging processes in the power supply section.

External causes such as unstable mains supply or faulty machine wiring were excluded by operating the unit independently on the test bench. The root cause was clearly located inside the servopack.

Repair process and refurbishment

The servopack was completely disassembled and all assemblies were individually cleaned and inspected. Special focus was placed on the power supply and related sections.

The repair was carried out as a preventive refurbishment. The objective was not only to eliminate the current alarm but to restore long term operational stability. After reassembly, the unit was prepared for extended testing.

Testing and quality assurance

Final testing was performed over several hours under varying load conditions. Multiple cold and warm starts were carried out to simulate the previously critical situations. Voltage dips, mains fluctuations and load changes were deliberately applied.

Throughout the entire test procedure, alarm A.71 did not reappear. All internal voltages remained stable within specification and axis control was smooth and repeatable under all conditions.

Only after successful completion of all tests was the servopack released for return to the customer.

Preventive recommendation

This case clearly demonstrates that alarms like A.71 usually develop gradually rather than occurring suddenly. Especially with older Sigma II servopacks, preventive refurbishment is strongly recommended before unexpected machine downtime occurs. Early maintenance is typically far more cost effective than emergency repairs during production.

Further information such as price and delivery time for:

Yaskawa Servopack SGDH-08AE-SY202

More details about our Yaskawa repair expertise can be found here: Yaskawa SIGMA II repairs by Industrypart

Similar models we regularly repair:

SGDH-08AE-OY

SGDH-08AE-S

Technical specifications

| Parameter | Value |

|---|

| Model | Yaskawa SGDH-08AE-SY202 |

| Series | Sigma II |

| Software version | 0F214-0 |

| Input voltage | 220–230 V AC |

| Phases | Single phase |

| Output voltage | 0–230 V AC |

| Output phases | Three phase |

| Rated power | approx. 0.8 kW |

| Rated current | approx. 5.7 A |

| Protection class | IP1X |

| Cooling | Fan cooled |

| Manufacturer | Yaskawa Electric |

| Origin | Made in Japan |

Application environment and compatible equipment

The SGDH-08AE-SY202 is typically used in CNC machines, handling systems and industrial automation equipment. It is compatible with Yaskawa Sigma II servo motors of the corresponding power class and is commonly used for feed axes and precision positioning systems.

Functional description

The servopack provides power supply and closed loop control for the connected servo motor. It processes command values from the machine control, regulates current, torque and position and integrates multiple protection functions. Stable internal power supply is essential for reliable operation.

Alarms and troubleshooting

| Code | Description | Cause | Action |

|---|

| A.71 | Momentary power interruption | Internal supply instability | Repair servopack |

| A.33 | Overcurrent | Load or electronics | Inspect electronics |

| A.50 | Overload | Mechanical overload | Check axis |

| A.51 | Continuous overload | Permanent high load | Adjust process |

| A.70 | Voltage fault | Mains fluctuation | Check supply |

| A.45 | Fan error | Insufficient cooling | Inspect fan |

| A.10 | Power stage overcurrent | Short circuit or defect | Repair required |

Main assemblies

| Assembly | Function | Notes |

|---|

| Power module | Motor control | Thermally stressed |

| Power supply section | Internal voltages | Aging sensitive |

| Control board | Regulation and communication | Sensitive to voltage |

| Fan unit | Cooling | Regular inspection |

| Heatsink | Heat dissipation | Cleanliness required |