01.02.2026 by Viktor Siebert

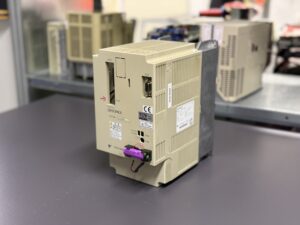

Yaskawa SGDB-20AM AC Servopack. When repair is technically possible but no longer economically reasonable

The Yaskawa SGDB-20AM AC Servopack arrived with a very clear fault description. According to the customer, the unit showed alarm “C” directly on the display immediately after power-on. This behavior occurred reproducibly, regardless of whether the servopack was installed in the machine or tested loose on the workbench.

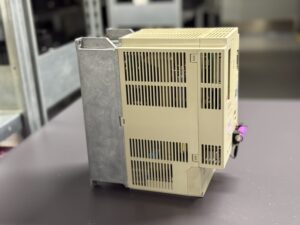

Already during the incoming inspection it was evident that this was not a classic wear-related fault, as we often see with Sigma I units. There were no thermal abnormalities, no obvious damage to the power stage, no burned tracks, no burst capacitors. Externally, the unit appeared unremarkable, which often makes such cases particularly difficult.

At our internal test bench, the picture changed slightly.

Instead of only displaying “C”, the unit showed alarm A.04. On Sigma I servopacks, this alarm very often indicates a problem in the non-volatile memory area of the control board (EEPROM). Typically, this affects internal initialization data, calibration values, or safety-relevant parameters that are checked during startup. If these data are no longer consistent or are corrupted, the unit will completely refuse to start.

Our technicians then fully disassembled the servopack and carried out a systematic inspection.

The power supplies were stable, and the power section could be operated without any issues using a known-good reference control board. This clearly showed that the power section, DC link, and output stage were electrically intact. The fault was clearly isolated to the original control board.

At this point, we reached a situation that we encounter repeatedly in practice and always address openly:

Not every control board can be repaired in a meaningful way.

Especially with older Sigma I devices, certain memory components can no longer be reliably reprogrammed or restored. In this case, our development team also confirmed that repair of the original control board was not possible. The only technically sound solution would have been a complete replacement of the board.

From a purely technical perspective, the servopack could have been restored:

We have suitable replacement boards, tested assemblies, dedicated test benches, and standardized procedures for exactly this type of device. In practice, however, the decisive question was: Does it still make economic sense for the customer?

After consultation with the customer, it became clear that replacing the control board would no longer provide sufficient value. The unit had already accumulated many operating hours and was part of a system that was expected to be modernized in the foreseeable future. In this context, the decision was understandable: the drive was returned to the customer unrepaired.

Cases like this are important, even if they may seem unsatisfactory at first glance. They clearly show where the limits of classical repair lie and why preventive maintenance is crucial for servopacks. A unit that is overhauled in time, with fans, capacitors, and critical components replaced early, is far less likely to develop such deep-seated memory faults. If maintenance is postponed for too long, however, failures with structural root causes can arise that are no longer economically solvable.

Our goal is to communicate this transparently. Not every repair ends with a green test report, but every case ends with a clear technical assessment and an honest recommendation for the customer.

Information about the mentioned Servopack: Yaskawa Servopack SGDB-20AM

Further details on our Yaskawa repairs can be found here: Yaskawa Sigma 1 Repair

📞 Feel free to contact us if you have any questions regarding your Yaskawa drive technology. Our team will be happy to assist you.

Device Overview

- Manufacturer: Yaskawa Electric

- Series: Sigma I

- Model: SGDB-20AM

- Device type: AC Servopack

- Protection class: IP1X

Technical Specifications

| Parameter | Value |

|---|

| Input voltage | 3-phase AC 200–230 V |

| Frequency | 50/60 Hz |

| Input current | approx. 12.0 A |

| Output voltage | AC 0–230 V |

| Output current | approx. 18.5 A |

| Motor power | approx. 2.0 kW (2.67 HP) |

| Cooling | Forced air cooling |

| Mounting type | Control cabinet unit |

Typical Application Environment

- CNC machines of older generations

- Machine tools and machining centers

- Special-purpose machines with Yaskawa Sigma I axis systems

- Industrial environments with 200 V power supply

Functional Description

The SGDB-20AM is an AC servo amplifier from the Sigma I series designed for precise control of Yaskawa servo motors. The unit processes command signals from the CNC or PLC, regulates current, torque, and position, and continuously monitors internal voltages, temperatures, and memory contents. Faults in the control board area lead to immediate startup inhibition to prevent uncontrolled motion.

Alarm Messages (Sigma I selection)

| Code | Description | Typical cause | Action |

|---|

| C | Initialization error | Internal control fault | Check control board |

| A.04 | Memory error | Corrupted EEPROM data | Replace control board |

| A.02 | Undervoltage | Unstable power supply | Check mains |

| A.10 | Overcurrent | Motor short circuit | Check power stage |

| A.20 | Overtemperature | Fan failure | Replace fan |

| A.30 | Encoder error | Signal loss | Check encoder |

| A.40 | CPU error | Control logic fault | Check board |

| A.51 | Regeneration error | Braking resistor issue | Check resistor |

| A.60 | Communication error | Signal problem | Check wiring |

| A.80 | Parameter error | Inconsistent data | Re-parameterize |

Main Assemblies

| Assembly | Function | Assessment |

|---|

| Control board | Logic, memory, monitoring | Defective, not repairable |

| Power stage | Motor drive output | Functional |

| DC link | Energy buffering | No abnormalities |

| Fan unit | Cooling | Functional |

| I/O interfaces | Communication | Functional |

Conclusion

This repair case clearly shows that not every failure is the result of wear alone. Memory errors in the control board often develop gradually and are the result of years of thermal and electrical stress. In such cases, partial repairs are no longer sufficient.

For this reason, we focus on preventive overhauls for comparable devices while they are still technically manageable. For the Yaskawa SGDB-20AM, we have spare parts, boards, and test infrastructure available. Whether a repair is reasonable, however, is always decided together with the customer technically sound and economically realistic.