23.01.2026 by Viktor Siebert

Repair of a Yaskawa SGDB-20ADPY193 Servopack with Alarm A.40

Initial Situation and Fault Description.

The Yaskawa Servopack SGDB-20ADPY193 was sent in by the customer with the information that the unit immediately displays alarm A.40 after power-on. No further operation was possible, as the servopack switched directly into the fault state. Neither a reset nor repeated power cycling changed the condition.

Alarm A.40 in the SGDB series is defined as a Main Circuit Voltage Error / Main Circuit Overvoltage Error. A characteristic feature of this alarm is that it occurs already during the internal initialization phase, before any external enable or command is applied. This behavior usually indicates an internal issue within the power section or the DC bus monitoring circuit.

Based on the fault description alone, it was already clear that this was not an external issue such as motor, wiring, or mechanical load, but an internal defect of the servopack.

Incoming Inspection and Initial Testing

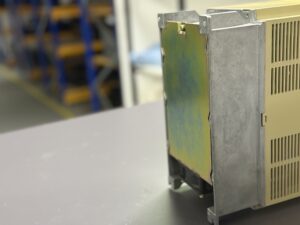

After receipt, the unit first underwent a visual inspection. The housing showed no external damage, however significant dust and dirt accumulation was visible around the ventilation openings. This indicated long-term operation in a control cabinet environment with insufficient cleaning or airflow maintenance.

Next, insulation and safety checks were performed with the unit de-energized. No short circuits to ground were detected on the power terminals, and the internal fuses appeared intact.

When the servopack was powered on at the test bench, the customer-reported fault was fully confirmed. Alarm A.40 appeared immediately after power-up, without any external enable signal applied. The behavior was fully reproducible.

Diagnosis and Root Cause

Because the alarm occurred instantly during startup, the diagnostic focus was placed on the DC bus and internal voltage monitoring circuits. In this area, the SGDB servopack continuously monitors the DC bus voltage and various internal reference voltages.

After opening the unit, clear signs of aging were found in the power electronics section. Several components involved in voltage generation and monitoring showed thermal stress and long-term aging effects. Such conditions typically develop over many years of continuous operation, elevated ambient temperatures, or insufficient cooling.

As a result of this aging, internal voltage levels drifted outside their permissible tolerance already during power-up. The protection logic of the servopack detected this deviation immediately and triggered alarm A.40 to prevent further damage.

An important detail in this case is that the fault occurred permanently and instantly, not intermittently. This is a strong indicator of an internal power or monitoring defect rather than an external influence.

Repair Process

As part of the repair, the servopack was completely disassembled and thoroughly cleaned. Dust and contamination were removed from the cooling paths to ensure proper heat dissipation.

In the next step, a preventive overhaul of the voltage-related assemblies was carried out. Components showing age-related drift or thermal stress were replaced. In addition, the cooling fan was inspected and replaced as a preventive measure to ensure long-term thermal stability.

After completing the repair work, the unit was reassembled and prepared for functional testing.

Testing and Quality Assurance

The repaired Yaskawa SGDB-20ADPY193 was tested on the in-house test bench. The test procedure included:

- Multiple power-on and power-off cycles to verify startup behavior

- Monitoring of DC bus voltage during initialization

- Thermal observation during extended operation

- Simulation of typical operating conditions without motor load

After repair, the servopack powered up without any fault indication, and alarm A.40 did not reappear. All internal voltage levels remained stable and well within their specified tolerances. Even after extended operation, the unit showed consistent and reliable behavior.

Information about the mentioned Servopack: Yaskawa Seropack SGDB-20ADPY193

Further details on our Yaskawa repairs can be found here: Yaskawa Sigma 1 Repair

📞 Feel free to contact us if you have any questions regarding your Yaskawa drive technology. Our team will be happy to assist you.

Technical Specifications

| Parameter | Value |

|---|

| Manufacturer | Yaskawa Electric |

| Series | SGDB |

| Model | SGDB-20ADPY193 |

| Input Voltage | AC 200–230 V |

| Phases | 3-phase |

| Output Voltage | AC 0–230 V |

| Output Current | 7.5 A |

| Motor Power | approx. 1.3 kW |

| Cooling | Forced air cooling |

| Design | Servopack for CNC applications |

| Origin | Made in Japan |

Typical Application Environment

The SGDB-20ADPY193 is typically used in CNC machine tools such as machining centers, lathes, and special-purpose machines. It controls feed axes with high demands on dynamic response and positioning accuracy.

These units are often operated continuously over many years, making regular maintenance and preventive refurbishment especially important.

Functional Description

The servopack converts three-phase AC mains voltage into a controlled output voltage for the servo motor. During operation, it continuously monitors:

- Mains voltage and phase condition

- DC bus voltage

- Power stage temperature

- Internal reference and auxiliary voltages

If any parameter exceeds its permissible range, the internal protection logic intervenes and prevents continued operation.

Alarm Messages and Troubleshooting (Excerpt)

| Code | Description | Cause | Action |

|---|

| A.40 | Main Circuit Voltage Error | Internal DC bus voltage deviation | Inspect and repair servopack |

| A.30 | Regeneration Error | Fault in braking or regeneration circuit | Check regeneration circuit |

| A.81 | Heat Sink Overheat | Excessive temperature | Inspect cooling and fan |

| A.70 | Overload | Excessive load condition | Check mechanics and parameters |

Main Assemblies

| Assembly | Function | Notes |

|---|

| Power board | Energy conversion and current control | thermally stressed |

| Control board | Regulation and monitoring | sensitive to aging |

| DC bus section | Voltage stabilization | critical for A.40 |

| Fan assembly | Cooling of power stage | replaced preventively |

Conclusion

Alarm A.40 on the Yaskawa SGDB-20ADPY193 is a clear indication of an internal issue in the voltage or power section. In this case, the root cause was age-related drift of internal components, leading to immediate protective shutdown during power-up.

Through professional repair and preventive refurbishment, the servopack was fully restored. Final testing confirmed stable and reliable operation.

Timely overhaul of such units helps prevent unplanned machine downtime and significantly extends the service life of drive electronics.