16.02.2026 by Viktor Siebert

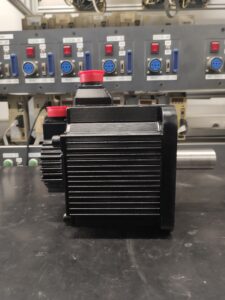

/ Repairreport Yaskawa AC Servo Motor SGMGH-30ACA6S

Initial Situation and Symptoms.

The motor arrived as a typical emergency case: insulation fault, intermittent drive shutdowns, and the characteristic smell of moisture inside an electrical machine.

The root cause became immediately visible:

The motor had completely drawn in coolant emulsion.

The contamination was not limited to the exterior. The emulsion had penetrated deep into:

- The winding chamber

- The bearing areas

- The encoder housing

Insulation measurements confirmed the critical condition.

We detected a short circuit between windings, and feedback signals from the encoder were unstable.

In such cases, there is a significant risk of damaging the servo amplifier if the issue is not resolved immediately.

Condition at Incoming Inspection

After complete disassembly, the full extent of damage became clear:

- Emulsion residues inside the housing

- Corrosion traces in the encoder area

- Reduced insulation resistance

- Phase-to-phase winding fault

- Encoder malfunction with signal dropouts

Important note:

Drying alone is not a solution. Coolant emulsion leaves conductive residues. If these remain inside the motor, the failure will reappear.

Disassembly and Structured Cleaning Process

The repair followed a defined industrypart workflow:

- Complete disassembly down to the winding chamber

- Mechanical pre-cleaning of all contaminated components

- Separation of electrical and mechanical assemblies

The cleaning process was performed in two stages:

- Degreasing and removal of emulsion films

- Residue-free rinsing process to eliminate conductive deposits

Controlled Drying and Electrical Recovery

A controlled multi-stage drying process was essential.

Moisture does not only remain on surfaces it penetrates insulation layers and capillary structures.

Our process included:

- Temperature-controlled drying cycles

- Intermediate insulation measurements

- Phase-to-phase and phase-to-ground verification

After stabilization of insulation values, the motor passed electrical acceptance limits.

Replacement of All Wear Components

Whenever a motor has drawn coolant, certain parts must always be replaced:

- All bearings

- All seals and O-rings

- Cable glands and sealing interfaces

- Encoder-related sealing components

The original encoder was beyond recovery and was replaced with:

Encoder UTSIH-B17CK

Encoder Installation, Adjustment and Programming

After mechanical installation, the following steps were performed:

- Electrical verification (supply voltage, signal stability)

- Mechanical alignment and positioning

- Parameter adjustment for operation with Yaskawa SGDH-30AE-OY

- Functional test under closed-loop control

Stable feedback is critical in Sigma II systems. Encoder faults typically trigger immediate alarm conditions.

Final Testing and Release

The motor was tested under real operating conditions:

- Warm-up cycle

- Acceleration and braking sequences

- Current consumption analysis

- Thermal behavior monitoring

- Extended endurance test

Only after stable performance under load was the motor released for operation.

Final Result

✔ Insulation values restored within specification

✔ Winding electrically stable

✔ Complete bearing replacement

✔ New encoder UTSIH-B17CK installed

✔ Stable operation with SGDH-30AE-OY

✔ Full load test passed

The motor was successfully returned to production-ready condition.

formation about the mentioned Servopack and Servomotor:

More information about our Yaskawa repairs can be found here.

📞 Feel free to contact us if you have any questions regarding your Yaskawa drive technology. Our experienced team is always ready to assist you.

Yaskawa AC Servo Motor SGMGH-30ACA6S

System: SGDH-30AE-OY (Sigma II)

IDENTIFICATION

Manufacturer: Yaskawa Electric

Series: Sigma II

Motor Type: SGMGH-30ACA6S

Production Date: 04/2001

Serial Number: B0041F843210002

Country of Origin: Japan

NAMEPLATE DATA

| Parameter | Value |

|---|

| Rated Power | 2.9 kW |

| Rated Torque | 18.6 Nm |

| Rated Speed | 1500 rpm |

| Rated Voltage | 200 V |

| Rated Current | 23.8 A |

| Duty Cycle | Continuous (CONT.) |

| Insulation Class | F |

SYSTEM CONFIGURATION

Servo Amplifier: Yaskawa SGDH-30AE-OY

Voltage Class: 200 V

Control Type: Sigma II Digital Servo

Encoder (after repair): UTSIH-B17CK

Feedback Type: Incremental

FAILURE DESCRIPTION

- Insulation breakdown

- Coolant emulsion ingress

- Phase-to-phase short circuit

- Encoder failure

- Corrosion inside feedback housing

TYPICAL SIGMA II (SGDH) SERVICE-RELEVANT ALARMS

| Alarm Code | Description | Typical Cause |

|---|

| A.10 | Overcurrent | Short circuit / mechanical blockage |

| A.30 | Regeneration Fault | Brake resistor / DC bus issue |

| A.40 | Main Circuit Voltage Fault | Supply instability |

| A.C8 | Absolute Encoder Fault | Data inconsistency |

| A.C9 | Encoder Communication Error | Cable or encoder failure |

| A.CA | Encoder Parameter Error | Configuration mismatch |

| A.Cb | Encoder Echo Back Error | Feedback signal disturbance |