14.11.2025 by Viktor Siebert

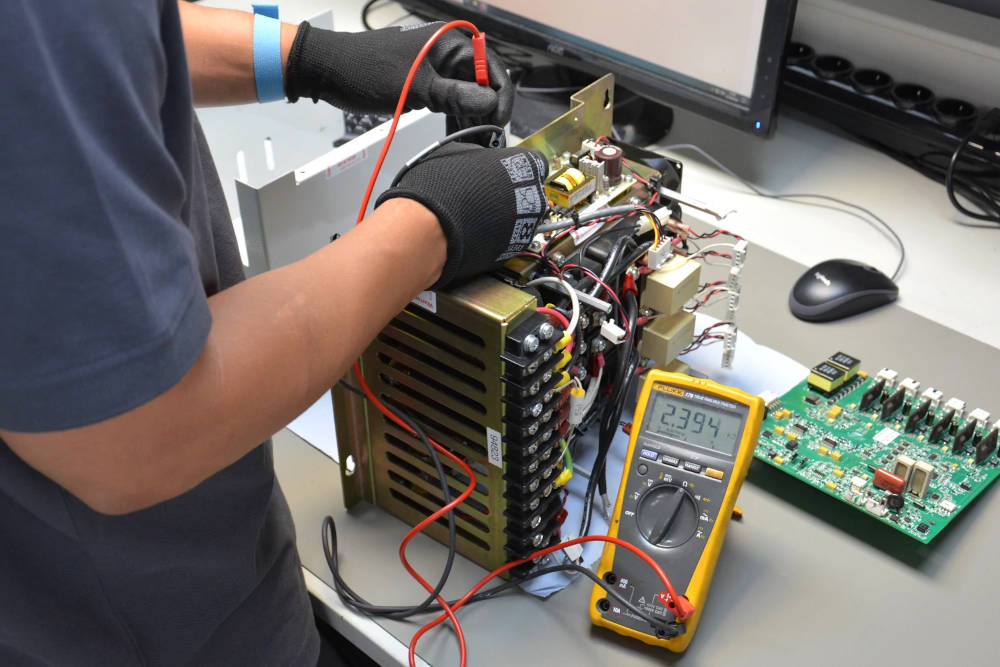

Safety and Performance Testing for HAAS Drives

Whether during repair or preventive maintenance of HAAS components, long-term reliability and protection against unplanned downtime can only be achieved through structured and consistent testing.

Reliable production depends on reliable components. That is why all HAAS modules undergo comprehensive electrical, thermal, and functional testing after repair. Our test benches simulate real operating conditions, ensuring consistent performance, predictable service life, and a sustainable, safety-oriented maintenance strategy.

Our Testing Processes for HAAS Drive Technology

- Fault analysis and precise localization

- Visual inspection and professional cleaning

- Replacement of defective components

- Electrical, thermal, and functional testing

- Simulation of real operating conditions

- Testing of control and communication interfaces

- Verification of alarm states

- Current, voltage, and temperature monitoring

- Complete documentation and structured checklists

- Long-term endurance testing

- Parameter verification and adjustment after repair

Through these comprehensive test procedures, we ensure that repaired HAAS drives and amplifiers meet high safety and performance standards and are ready for reliable operation immediately after reinstallation.

In addition, we also offer further test procedures for different manufacturers.