18.07.2025 by Viktor Siebert

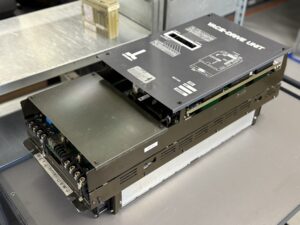

Repair of an Okuma VACIII-D22 Spindle Drive (1006-1232)

Recently, we received a heavily damaged Okuma SpindleDrive VACIII-D22, part number 1006-1232, for repair. The unit came from an Okuma LU15 turning machine that has been in use at the customer’s facility for many years.

Rare but severe failure

Already during the initial inspection, the extent of the damage was clear:

- Multiple transistor modules were blown

- The main relay had burned out

- The control board (drive board) had damaged output channels for the power modules

- The regeneration stage was also defective

Such damage is often declared “non-repairable” by many providers and even by the manufacturer. For the customer, a replacement unit would have cost nearly €17,000, which was not feasible given the age of the machine.

A customer who trusts Okuma machines

The operator exclusively uses Okuma machines in his company he sees them as precise, reliable, and high-quality in handling. He was referred to our company through a professional network. The decision to repair was made quickly, as the repair price was quoted clearly and fairly in advance with no hidden costs.

Detailed repair process

Our master technician took on the challenge successfully. The repair steps were as follows:

- Disassembly and visual inspection

The entire power unit was disassembled into its subassemblies. All components were visually and electrically inspected.

- Identifying defective parts

Over 70 components were found defective, including:

- Power transistors

- Main relay (load relay)

- Components of the regeneration circuit

- Gate driver components and control paths on the board

- Replacement & preventive overhaul

- All power modules were replaced

- The control board was fully overhauled: damaged channels repaired, traces checked, and aging components replaced

- Capacitors, protection diodes, signal transistors and other small parts were exchanged

- Final assembly and functional testing

- The unit was reassembled after repair

- A preliminary test on our test bench was performed to verify fundamental functions

Load test in a real Okuma machine

A special feature of our workshop: In addition to test benches, we also operate a fully functional Okuma machine with original control. The repaired unit was tested under real-world conditions including load, spindle control, braking cycles, and thermal behavior.

Only after successfully passing this long-term test was the unit released.

Result and customer experience

The repair took around 25 hours, slightly more than standard, but justified in this case. All spare parts were available in stock, so there were no delays.

The customer was kept informed throughout the process, especially when it became clear how extensive the damage was. He was positively surprised that the original flat rate price was maintained.

The machine has now been running flawlessly in multi-shift operation for over two weeks. We’re pleased not only with the successful repair but also with having gained a new, satisfied customer who hasn’t lost faith in professional repair services.

Price and Delivery Time for Okuma VACIII D22 (1006-1232) Drive Unit

For more information about our Okuma repairs, please click here.

📞 Feel free to contact us if you have any questions regarding your Mitsubishi drive technology. Our experienced team is always ready to provide you with expert advice and support.

Technical Details & Data

Device Specifications

Alarm Messages and Troubleshooting

| Alarm | Description | Possible Cause | Solution |

|---|

| 08 | Communication error | Connection disturbed | Check cables and connections |

| 10 | Motor cable overcurrent | Short-circuit in cable or motor | Check/replace cable and motor |

| 11 | Inverter bridge short-circuit | Defective inverter or IGBT | Replace inverter or IGBT |

| 12 | Regenerator IGBT short-circuit | Defective regenerator | Replace regenerator |

| 14 | Input voltage drop | Power supply issues | Check power supply |

| 15 | Open phase | Missing or unbalanced network phases | Check phases, correct power connections |

| 16 | Loss of arithmetic voltage (+5V low) | Defective power supply | Replace power supply or PCB |

| 17 | UVP, power circuit low voltage | Insufficient voltage, defective components | Check/replace power supply and PCB |

| 18 | Interval loop error | Control loop instability | Verify control loop settings |

| 19 | Motor overload | Motor overload, wiring error | Reduce load, check wiring |

| 20 | Heat sink overheat | Insufficient cooling | Check/replace fans |

| 21 | Data setting abnormal | Incorrect parameters | Check and correct settings |

| 30 | Excessive velocity deviation | Encoder issues | Check/replace encoder |

| 31 | | |

| 34 | Occurs in VACII and VACIII | Hardware failure | Inspect and replace hardware |

| 37 | PG feedback error | Encoder or cable issue | Check wiring and encoder |

| FF | RAM error | PCB memory error | Replace PCB |

- | No enable via optical fiber, only display 01 | Optical fiber communication error | Check fiber optic cable

Components (Board Numbers)

| Board | Function | Notes |

|---|

| E4809-045-145-C (1006-1107) | Control board (Drive Board) | Gate drivers, control channels |

| E4809-705-002 (VACIII‑D22) | Power board (power stage) | IGBT output stage |

| PWR Board (1006-1232) | Special high-power board | Optimized for D22 variant |