17.12.2025 by Viktor Siebert

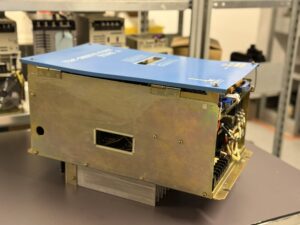

Repair of an Okuma VAC-Drive Unit Type A D8-A sustainable overhaul after third-party repair

The Okuma VAC-Drive Unit Type A D8-A was sent to us by the customer with a clearly documented history. The unit had already been repaired by a third-party service provider, but after a short period of operation it failed again. In total, the customer had to return the unit twice without achieving stable operation.

Already during incoming inspection, a typical picture of improper intervention became apparent. Partial repairs had been carried out without fully eliminating the underlying causes. Individual assemblies appeared superficially repaired, while other critical areas had been completely left untouched. For the customer, this meant repeated downtime, production losses and growing mistrust regarding the repairability of this series.

Our workshop has been repairing Okuma VAC drives for more than 18 years. The known weak points of this series are familiar to us from numerous real-world failure cases. The goal with such units is never a short-term repair, but a preventive overhaul that enables long-term stable operation.

As a first step, a complete functional analysis was performed under controlled conditions. It quickly became evident that the root cause was located in the transistor gate control section. Two channels did not provide clean, symmetrical control signals. This caused individual power transistors to be operated periodically outside their safe operating area. The result was recurring failures of the power stage without the primary cause being eliminated.

Such fault patterns are particularly critical because they do not become visible immediately. The unit can initially start up, accept load and appear stable, until thermal or dynamic effects once again lead to failure.

The repair was therefore carried out consistently and comprehensively. All relevant assemblies were tested, measured and evaluated. In total, more than 60 components were replaced, including parts of the control circuitry, signal processing, auxiliary power supply and thermally stressed sections. The objective was not only to eliminate the acute fault, but also to remove all known aging-related and secondary risk factors.

After completion of the repair, the unit underwent an extensive test phase. Testing was carried out not only under no-load conditions, but also under load, in order to verify the behavior of the transistor control over the entire operating range. Temperature behavior, signal stability and protective functions were monitored over an extended period.

Only after passing long-term testing was the unit released for delivery. Since then, the VAC-Drive Unit has been operating reliably at the customer’s site without any further failures.

Preventive approach for Okuma VAC drives

This repair clearly demonstrates that, especially for older Okuma spindle drives, a selective repair is not sufficient. These units are electrically complex, and individual defective components are often only symptoms of deeper underlying problems.

A preventive repair approach significantly extends service life, reduces secondary damage and ensures long-term machine availability. In many cases, this approach is more economical than repeated partial repairs or attempts to source replacement units on the market.

Conclusion

The successful overhaul of this Okuma VAC-Drive Unit Type A D8-A clearly illustrates how important experience, systematic diagnostics and preventive repair strategies are. Especially with previously repaired units, it is not the individual replaced part that determines success, but a comprehensive understanding of the overall system.

For us, a reliably repaired unit that operates long-term is more valuable than any short-term solution. This principle has guided our work in the repair of Okuma drive systems for many years.

Price and Delivery Time for Okuma VAC-Drive Unit Typ A D8-A (Order Nr. 1006-1216)

For more information about our Okuma repairs, please click here.

📞 Feel free to contact us if you have any questions regarding your Mitsubishi drive technology. Our experienced team is always ready to provide you with expert advice and support.

Technical Details & Data

Device Specifications

Technical Overview

Device designation

Okuma VAC-Drive Unit Type A D8-A

Okuma order number

1006-1216

Series

VAC-I / VAC-A spindle drive series

Main control board

E4809-045-084-G

Order number: 1106-1102

Power class

approx. 7.5 kW continuous power

up to approx. 11 kW short-term operation

Input voltage

200–220 V AC

3-phase, 50/60 Hz

DC link

DC intermediate circuit with regenerative braking function

Cooling

Forced air cooling via rear-mounted fan unit

Weight

approx. 28–30 kg

Typical machines

Okuma LB series, LC series

OSP5000, OSP5020, early OSP7000 controls

Operating environment and function

The Okuma VAC drive units of the A series are classic transistor-based spindle drives with regenerative energy feedback. They were used in many Okuma turning machines of the 1980s and early 1990s and are well known for their robust mechanical design.

At the same time, these units are considered electrically demanding, as they react sensitively to incorrect control signals, aged components and improper repairs. Especially in the area of transistor gate control and internal auxiliary power supplies, even minor deviations can lead to secondary failures.

Diagnostic and status indicators

The unit is equipped with several diagnostic LEDs:

- POWER (green): DC link charged

- LOSS (red): Undervoltage or loss of supply

- CPUALM (red): Error in the control circuit

- M1 / M2 / M3: Binary code for fault identification

- Status LEDs 1–13: Detailed indication according to the Okuma fault table

These indicators allow precise fault localization, but they require experience. A purely table-based fault search is not sufficient for these units.

Typical alarms and faults

| Indication | Meaning | Typical cause |

|---|

| LOSS | Undervoltage | Aged power supplies, unstable auxiliary voltage |

| OV | Overvoltage | Defective braking control |

| UV | Undervoltage | Fault in charging or power supply section |

| PH | Phase loss | External supply or internal rectification |

| IOC / IOCR | Overcurrent | Faulty transistor control |

| CPU ALM | CPU fault | Unstable supply, logic error |

| LOOP | Control loop fault | Asymmetrical signals |

| WDOG | Watchdog | Timing fault in control logic |

Main components of the unit

| Assembly | Designation | Function |

|---|

| Control board | E4809-045-084-G | Logic, regulation, control |

| Power section | D8-A | Transistor power stage |

| DC link | internal | Energy buffering |

| Braking module | integrated | Regeneration |

| Power supply section | integrated | Auxiliary voltages |

| Fan unit | rear-mounted | Cooling |