06.05.2025 by Viktor Siebert

When the Spindle Gets Too Loud – Repair of a Mitsubishi Spindle Motor SJ-4-18.5BW4

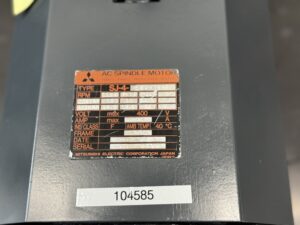

A short while ago, we received a Mitsubishi AC spindle motor of the type SJ-4-18.5BW4 from a machine service company for repair. The reason: during operation, the motor was noticeably loud and repeatedly showed encoder errors at higher speeds. For the machine operator, this was a serious issue – because without a functioning spindle, production grinds to a halt.

The Symptoms: Loud, Unstable, Error-Prone

The customer reported that the motor had recently become unusually loud when ramping up – a typical sign of worn-out bearings. On top of that, there were frequent issues with spindle positioning, clearly pointing to encoder problems. Especially at high speeds, the machine became increasingly unreliable and difficult to control. For the operator, this meant recurring breakdowns, inaccurate machining, and a lot of unplanned downtime.

Our Diagnosis and Repair Process

Once the motor arrived at our workshop, we carried out a thorough inspection. The bearing noise was immediately confirmed – the ball bearings were heavily worn and caused pronounced operational noise. Further testing of the encoder revealed significant weaknesses: the sensor inside the encoder was defective, and the internal electronics showed intermittent failures.

We decided to perform a complete overhaul of the motor, which included:

- Professional replacement of all ball bearings

- Thorough cleaning of the motor

- Replacement of the defective encoder sensor

- Refurbishment and recalibration of the encoder electronics

- Replacement of all seals and connectors

- New paint coating for the motor

- Extensive functional testing over time

Thanks to the adjustment and testing of the encoder using our test bench, we ensured that the spindle position feedback was once again accurate and stable – a crucial factor for reliable CNC control.

Quick Turnaround – in Just 5 Days

Since the customer is a service provider working on behalf of machine operators, a fast turnaround was especially important. We were able to complete the repair within just five working days – from delivery to shipment of the fully tested and overhauled motor.

Conclusion: Early Detection Pays Off

This case clearly illustrates how important it is to take unusual noise and encoder malfunctions seriously. If such signs are ignored, a complete failure may follow – with high costs for downtime and spare parts. Thanks to the timely repair, we not only saved the motor but also helped our customer quickly restore machine availability.

More Info & Contact

To mentioned Yaskawa Motor: Mitsubishi AC spindle motor SJ-4-18.5BW4

More details about our Mitsubishi repair services can be found here:

Mitsubishi Motor Repair by Industrypart

We regularly repair similar models, including:

SJ-4-18.5AZM

📞 Feel free to contact us with any questions about your Mitsubishi drive technology.

Our expert team is happy to help!

Motor Specifications

Here is a summary of the key technical specifications:

| Specification | Value / Description |

|---|

| Model | Mitsubishi AC Spindle Motor SJ-4-18.5BW4 |

| Rated Power | Approx. 11.5 kW (continuous), 15 kW (30 min) |

| Max. Speed | 6000 rpm (max) |

| Shaft Diameter | 48 mm |

| Operating Voltage | ~400 VAC (inverter output) |

| Rated Current | Approx. 52 A |

| Cooling | Self-ventilated (integrated fan) |

| Integrated Encoder | Incremental encoder |

Typical Applications in Machines

The robust construction and high torque at low speeds make these motors ideal for heavy-duty machining and thread cutting in CNC lathes. At the same time, the maximum speed of 6000 rpm allows for a wide range of applications – from rough cutting to fine finishing. In addition to Mazak machines, similar Mitsubishi spindle motors are also found in equipment from other manufacturers that use Mitsubishi CNC control systems. In general, SJ models are used wherever a reliable spindle drive with around 15–18 kW of power is required – for example, in conventional and CNC-controlled lathes, machining centers, and boring mills.

Drive System and Control (Mitsubishi Drives)

To precisely control such an AC spindle motor, it must be powered by a suitable frequency inverter or spindle amplifier. Mitsubishi offers dedicated CNC spindle amplifiers in its MDS series for this purpose. In CNC machines with Mitsubishi control systems (Meldas/Mitsubishi CNC), modules from the MDS-A, MDS-B, or MDS-C series are commonly used.

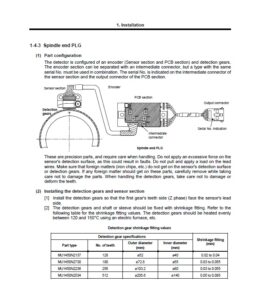

Encoder and Feedback System

A key component of the SJ-4-18.5BW4 is the integrated rotary encoder, often referred to by Mitsubishi as a PLG (Pulse Generator). It is mounted at the rear of the motor and continuously delivers pulses for measuring rotational speed and position.