11.02.2026 by Viktor Siebert

Repair of a Mitsubishi Servo Drive Unit MDS-C1-V2-2020 with Sporadic Alarm 32

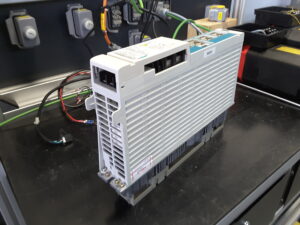

The Mitsubishi Servo Drive Unit MDS-C1-V2-2020 was delivered to us due to a sporadically occurring Alarm 32. The customer reported that the machine stops irregularly, the alarm behavior cannot be reproduced reliably and in some cases disappears after a restart. In the MDS-C1 series, Alarm 32 is clearly assigned to the power stage or power module and indicates an internal overcurrent or a fault in the power section.

Initial Situation and First Analysis

During incoming inspection, the overall condition initially appeared unremarkable. The unit powered up correctly, the status indicators operated normally and no external damage, burn marks or previous repair work were visible. Both axes could be rotated during test operation, and the motor ran smoothly without any unusual noise. This behavior is typical for power modules with early stage damage, where the fault only occurs under specific thermal or dynamic conditions.

Since Alarm 32 is safety related and directly affects the power stage, the unit was not subjected to further continuous operation tests, but was immediately prepared for an in depth analysis.

Detailed Diagnosis

After disassembling the unit, all assemblies were first cleaned and visually inspected. In particular, the power module and the power board showed slight thermal discoloration in the area of individual power transistors, which does not necessarily lead to an immediate total failure during normal operation. Measurements on the IGBT paths confirmed a temperature dependent leakage current that was uncritical when cold but increased significantly as the unit warmed up.

In parallel, the gate drivers, optocouplers and DC link voltage were checked. The control board operated without errors, and the DC bus supply was also stable. This further confirmed the suspicion of an incipient defect in the power stage, explaining the sporadic alarm behavior.

Repair Work

As part of the repair, the complete power module A2-V2-2020 was replaced. In addition, thermally stressed components such as snubber capacitors and thermal interface materials were replaced as a preventive measure. All power semiconductors were reinstalled and tightened with defined preload to ensure optimal heat dissipation.

After reassembly, an electrical safety test was performed along with verification of all power and feedback connections. Special attention was paid to proper grounding and clean contact of the DC bus connections.

Functional Test and Long Term Test

The repaired MDS-C1-V2-2020 was then operated on our test bench with a reference motor. Both axes were tested under varying loads, different speeds and multiple acceleration and deceleration cycles. The previously reported Alarm 32 did not reoccur, even under continuous thermal load.

Finally, the unit was operated in continuous mode for several hours. Current consumption, temperature behavior and control performance remained stable and within specified limits. After successful completion, a detailed test report was created and the unit was approved for return shipment.

Conclusion

This case clearly demonstrates that sporadic alarms on servo drives are often early warning signs of progressive defects. Through targeted analysis and timely replacement of the power stage, an unplanned machine failure was avoided and operational reliability was sustainably restored.

To mentioned Mitsubishi Drive: Mitsubishi Servo Drive Unit MDS-C1-V2-2020

More details about our Mitsubishi repair services can be found here:

Mitsubishi drive Repair by Industrypart

📞 Feel free to contact us with any questions about your Mitsubishi drive technology.

Our expert team is happy to help!

Mitsubishi Servo Drive Unit MDS-C1-V2-2020

Overview

Proven Mitsubishi Servo Drive Unit from the MDS-C1-V2 series, developed for precise CNC applications with high dynamic performance. The unit offers high reliability, compact design and easy integration into multi axis systems. Ideal for machine tools with high power demand and precise axis control.

Model Designation

MDS = Mitsubishi Drive System

C1 = C1 series (modular 200 V drive series)

V2 = 2 axis servo amplifier

2020 = Power rating 2.0 kW per axis

Technical Data

| Feature | Value |

|---|

| Output power | 2.0 / 2.0 kW |

| Input current | 28 A (DC 270–311 V) |

| AC auxiliary supply | 0.2 A, single phase 200–230 V, 50/60 Hz |

| Output | 3 phase 155 V, 0–240 Hz |

| Rated output current | 13 A per axis |

| Cooling | Forced air cooling (fan) |

| Weight / dimensions | n. a. |

Connections and Interfaces

DC bus (P/N)

U/V/W x2 motor outputs

CN1 / CN2 control and communication

CN3 encoder feedback

CN8 brake control

LED / 7 segment display

PE connection to be implemented with low impedance

Control Boards and Assemblies

| Assembly | Designation | Quantity |

|---|

| Control board | RK112A-22 or BN634A980G51 | 1 |

| Power board | RL122B-V2 or BN638A153G51 | 1 |

| Power module | BKO-NC1207 H94 or A2-V2-2020 | 1 |

Typical Alarms

32 Power module error / overcurrent

33 Overvoltage

08 Overheat

17 A/D error

50 / 51 Overload

Typical Applications

CNC lathes

Machining centers

Robot axes

Tool and mold making

Service Notes

Regular cleaning of fan and heat sink

Preventive inspection of power components

Parameter backup before service work

No insulation measurement while installed