20.02.2026 by Viktor Siebert

Repair of a Mitsubishi MDS-DH-CV-450 with Defective Output Stage Drive and Alarm C

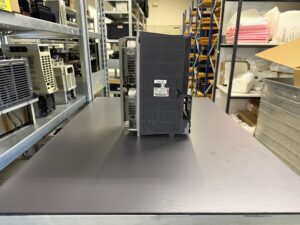

The Mitsubishi MDS-DH-CV-450 power supply unit was delivered with the fault description “Alarm C.” According to the customer, the error occurred immediately after switching on the machine. The system did not enter operational mode but stopped during initialization.

Externally, the unit showed minor housing damage caused during transport. However, this damage was not related to the electrical failure. The root cause was clearly internal.

Initial Situation and Fault Symptoms

After power-up, the DC bus voltage was built up, but the power stage was not released in a stable manner. The power supply aborted the startup sequence and displayed Alarm C.

The connected servo amplifiers did not receive a stable DC bus voltage. Each restart resulted in the same reproducible fault.

The mechanical housing damage had no influence on the failure. The defect was purely electronic.

Technical Analysis

The MDS-DH-CV-450 operates with a rectifier and DC bus structure. The power semiconductors are controlled via a separate driver stage. This driver stage is galvanically isolated and supplied by its own internal power section.

Diagnostics revealed:

- Unstable signal levels in the output stage drive

- Missing clean release of the power modules

- Protective shutdown during initialization

- No damage to the power semiconductors

The cause was age-related degradation of components within the driver and supply section. After years of thermal stress, typical effects include:

- Capacitance loss in supply filters

- Reference voltage drift

- Unstable gate driver supply

- Delayed or faulty release of the output stage

The protection logic responded correctly and prevented possible damage to the power modules.

Repair Measures

The repair was carried out systematically and preventively:

- Removal and inspection of the driver section

- Replacement of aged supply and filter components

- Stabilization of the output stage drive

- Verification of galvanic isolation

- Inspection of DC bus monitoring

- Cleaning of heat sinks

- Fan function test under load

- Visual inspection of solder joints in the power section

The power semiconductors themselves were undamaged and did not require replacement.

Transport and Packaging. An Important Side Aspect

Although the electrical defect was not caused by transport, the unit showed minor housing damage. This highlights an increasingly important issue.

The MDS-DH-CV-450 weighs approximately 10 to 12 kg. Despite this moderate weight, it has high mass density due to massive heat sinks and power components. In the case of insufficient packaging, significant acceleration forces act on the housing and PCBs during drops.

Electronics can often be repaired. Mechanical special parts often cannot.

For units of this generation, housings, front covers, and special mounting frames are usually no longer available as spare parts. A mechanically destroyed housing can therefore mean the economic end of an otherwise repairable unit.

With increasing system age, reproduction of housing components, for example via additive manufacturing or CNC machining, will become more relevant. At present this is rarely economical, but in the future it will likely gain importance.

Proper packaging is therefore not just transport protection, but part of sustainable maintenance strategy.

Final Functional Test

The test was performed under realistic operating conditions:

- 400 V mains supply

- Simulated servo load

- Multiple start cycles

- Four-hour continuous operation

- Thermal monitoring of the power section

Result:

- Stable DC bus voltage

- Clean initialization of the power stage

- No further alarm messages

- Thermally stable behavior

The output stage drive operated again with stable signal levels.

Conclusion

The defect of the MDS-DH-CV-450 was age-related and affected the output stage drive circuitry. Through targeted repair, full operational safety was restored.

At the same time, this case demonstrates the importance of careful packaging and responsible handling of industrial electronics that are no longer in production.

To mentioned Mitsubishi Drive: Mitsubishi Power Supply Unit MDS-DH-CV-450

More details about our Mitsubishi repair services can be found here:

Mitsubishi drive Repair by Industrypart

📞 Feel free to contact us with any questions about your Mitsubishi drive technology.

Our expert team is happy to help!

Technical Specifications

| Parameter | Value |

|---|

| Manufacturer | Mitsubishi Electric |

| Device Type | Power Supply Unit |

| Model | MDS-DH-CV-450 |

| Series | MDS-DH Series |

| Power | 37 kW |

| Input Voltage | 3AC 380–440 V |

| Output Voltage | DC 513–648 V |

| Input Current | approx. 85 A |

| Control Type | DC bus supply for servo and spindle modules |

| Cooling | Forced air cooling |

| Weight | approx. 10–12 kg |

| Ambient Temperature | 0 to 55 °C |

| Mounting | Control cabinet installation |

| Origin | Japan |

| Product Status | Discontinued |

Operating Environment and Applications

The MDS-DH-CV-450 is used in CNC machine tools, especially in:

- Machining centers

- Lathes

- Gantry milling machines

- Multi-axis production systems

It supplies multiple servo and spindle modules via a shared DC bus.

The unit is designed for industrial control cabinet environments and requires:

- Stable mains voltage

- Adequate ventilation

- Proper grounding

- Controlled ambient temperature

Functional Description

The MDS-DH-CV-450 converts three-phase mains voltage into a stable DC bus voltage. This serves as the energy source for connected axis and spindle amplifiers.

Functional sections:

- Rectifier section

- DC bus

- Regeneration monitoring

- Output stage drive

- Protection logic

Protection functions include overcurrent, overvoltage and overtemperature monitoring Alarme

Alarm Messages and Troubleshooting

Excerpt from the MDS-D/DH alarm list

| Alarm Code | Description | Possible Cause | Recommended Action |

|---|

| 10 | Insufficient voltage | DC bus undervoltage | Check mains supply |

| 24 | Grounding | Motor cable short to PE | Perform insulation test |

| 30 | Over regeneration | Regeneration overload | Check brake resistor |

| 32 | Power module overcurrent | Overcurrent in power module | Check power stage |

| 33 | Overvoltage | DC bus overvoltage | Check mains quality |

| 45 | Fan stop | Fan failure | Replace fan |

| 50 | Overload 1 | Continuous overload | Reduce load |

| 61 | PSU overcurrent | Overcurrent in supply module | Check PSU module |

| 71 | Instantaneous power interruption | Mains interruption | Check supply |

| 73 | Over regeneration PSU | Regeneration above 100% | Check brake resistor |

Component Overview

| Assembly | Designation | Function | Notes |

|---|

| Control Board | RK415D-21 | Drive control and protection logic | Susceptible to aging under thermal stress |

| Power Board | RM462A-4 | Rectification and DC bus | Thermal monitoring critical |

| Gate Driver Section | Integrated | Output stage control | Critical area in aging failures |

| Heat Sink | Aluminum profile | Heat dissipation | Clean regularly |

| Fan Unit | Axial fan | Forced cooling | Preventive replacement recommended |