17.02.2026 by Viktor Siebert

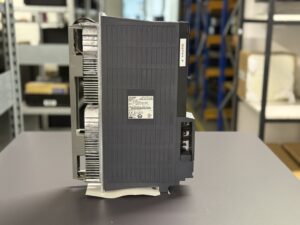

A Mitsubishi MDS-D2-V2-8040 servo drive unit failed without warning

When Production Suddenly Stops.

Everything was running smoothly.

The machining process was stable, cutting conditions were normal, and nothing indicated an upcoming issue.

Then, without warning, the machine stopped.

The cause was quickly identified: a Mitsubishi MDS-D2-V2-8040 Servo Drive had shut down during operation. No gradual performance degradation. No clear early signal. Just an abrupt stop in the middle of production.

For the customer, this meant immediate downtime. For us, it meant one thing: systematic diagnosis.

First Inspection No Visible Damage

When the unit arrived at our workshop, the housing showed no mechanical damage. No burn marks, no broken connectors, no obvious failure points.

But experience tells us that most failures inside servo drives are not visible from the outside.

After opening the unit, we noticed heavy contamination inside the cooling channels. Fine metallic dust and industrial debris had accumulated over time. The cooling fan showed noticeable bearing wear, and thermal stress discoloration was visible near the DC link capacitor section.

This was not a sudden catastrophic event.

It was the result of gradual aging.

Diagnostic Bench Analysis

The drive was connected to our controlled test bench with simulated CNC enable signals and regulated DC bus supply.

Immediately after activating the power stage, the drive triggered a power module overcurrent condition. The protection system did exactly what it was designed to do: shut down instantly to prevent further damage.

Detailed measurements revealed:

• Elevated DC bus ripple voltage

• Increased ESR values of the DC link capacitors

• Leakage behavior in the IGBT power module

• Reduced cooling efficiency due to fan wear

These factors combined created a thermally unstable power stage. During machining load, the current demand exceeded what the weakened components could safely handle.

The overcurrent protection was not the problem. It was the symptom.

Understanding the Root Cause

Servo drives like the MDS-D2-V2-8040 operate under continuous thermal stress. Over time:

Electrolytic capacitors lose capacitance and increase in ESR.

Cooling systems lose efficiency.

Power semiconductors experience cumulative thermal fatigue.

As ripple voltage increases, switching losses rise.

As switching losses rise, temperature increases.

As temperature increases, semiconductor stress accelerates.

Eventually, the protection system intervenes.

This is not a design flaw. It is the natural aging curve of power electronics.

The Repair Process

To ensure long-term reliability, we followed a structured refurbishment procedure:

• Complete disassembly and deep cleaning of cooling channels

• Replacement of all DC link capacitors

• Replacement of the IGBT power module

• Installation of a new cooling fan

• Inspection of solder joints exposed to thermal cycling

• Renewal of thermal interface material

• Electrical insulation and safety testing

After component replacement, the drive was subjected to a endurance test under dynamic load conditions.

We simulated:

Acceleration cycles

Deceleration cycles

Continuous torque load

Elevated ambient temperature

Encoder communication monitoring

DC bus ripple analysis

Throughout the entire test period, current behavior remained stable.

DC bus voltage stayed within specification.

No further overcurrent events occurred.

Why Preventive Maintenance Matters

This case highlights an important lesson:

Most servo drive failures are not random. They are predictable.

Capacitors typically show aging effects after 7 to 10 years depending on duty cycle.

Cooling fans often degrade after 3 to 5 years.

Dust accumulation significantly reduces heat dissipation efficiency.

Simple preventive actions can dramatically extend service life:

Annual internal cleaning

Scheduled fan replacement

Periodic DC bus capacitor ESR testing

Regular inspection of grounding and shielding

Preventive maintenance costs a fraction of unplanned downtime.

The Customer Benefit

After refurbishment, the Mitsubishi MDS-D2-V2-8040 was returned fully operational and tested under load.

The customer avoided:

Extended machine downtime

Costly new drive replacement

Unnecessary system reconfiguration

Instead, they received a sustainable, component-level repair that restores operational safety while extending equipment lifetime.

In industrial environments, reliability is not just about technology.

It is about continuity.

Conclusion

The failure of this Mitsubishi MDS-D2-V2-8040 Servo Drive was caused by gradual thermal aging combined with reduced cooling efficiency.

Protection systems worked correctly.

The electronics did what they were designed to do.

After professional refurbishment and extensive testing, the drive now operates within stable and safe parameters.

Electronic components age.

Cooling efficiency matters.

Preventive service prevents production stops.

And sometimes, what looks like a sudden breakdown is simply the end of a long and silent aging process.

To mentioned Mitsubishi Drive: Mitsubishi MDS-D2-V2-8040 Servo Drive Unit

More details about our Mitsubishi repair services can be found here:

Mitsubishi drive Repair by Industrypart

📞 Feel free to contact us with any questions about your Mitsubishi drive technology.

Our expert team is happy to help!

Technical Specifications

Device Type Mitsubishi Servo Drive Unit

Model MDS-D2-V2-8040

Manufacturer Mitsubishi Electric

Production Year 2015

Manual Reference Mitsubishi MDS-D/DH Series Instruction Manual

| Parameter | Value |

|---|

| Voltage | DC 270 to 311 V bus, 3 phase 200 to 230 V AC |

| Current | Input approx 21 A DC, Output up to approx 14.6 A |

| Power | 2.0 kW to 4.0 kW axis power depending on motor |

| Weight | approx 8 to 12 kg |

| Dimensions | approx 380 x 150 x 200 mm |

| Type | Digital servo drive with integrated power stage |

| Cooling | Forced air cooling |

| Control | Mitsubishi CNC servo interface |

| Manufacturer | Mitsubishi Electric Corporation |

| Production Year | 2015 |

| Manual Reference | MDS-D/DH Series Instruction Manual |

Application Environment and Compatible Equipment

The MDS-D2-V2-8040 is typically used in Mitsubishi CNC controlled machine tools such as:

Vertical machining centers

Turning machines

Grinding machines

Special multi axis machines

Compatible with:

Mitsubishi HF series servo motors

Absolute and incremental encoders

Mitsubishi CNC systems such as M700, M70

Functional Description

The MDS-D2-V2-8040 is a digitally controlled servo drive with integrated power stage.

Main functions:

Conversion of DC bus voltage into three phase motor voltage

Precise torque and speed control

Position control via CNC feedback

Integrated safety monitoring

The LED display alternates axis number and alarm code during faults Alarme

Alarm Messages and Troubleshooting

Based on Mitsubishi Manual Alarme

| Code | Description | Cause | Solution |

|---|

| 10 | Insufficient voltage | Bus undervoltage | Check mains |

| 17 | A D converter error | Current feedback failure | Check drive |

| 24 | Grounding | Motor cable earth fault | Check insulation |

| 30 | Over regeneration | Brake resistor overload | Check resistor |

| 31 | Overspeed | Motor overspeed | Check parameters |

| 32 | Power module overcurrent | IGBT overcurrent | Inspect module |

| 33 | Overvoltage | DC bus overvoltage | Check supply |

| 46 | Motor overheat | Motor thermal triggered | Inspect motor |

| 50 | Overload 1 | Continuous overload | Reduce load |

| 72 | Fan stop | Cooling fan failure | Replace fan |

Components

| Assembly | Description | Function | Inspection |

|---|

| Power module | IGBT stage | Motor drive | Thermal check |

| DC link capacitors | Bus capacitors | Voltage stabilization | ESR test |

| Control PCB | Logic board | Signal processing | Visual inspection |

| Fan | Cooling fan | Heat dissipation | Bearing test |

| Current sensor | Feedback sensor | Current detection | Offset check |

| Encoder interface | Feedback board | Position feedback | Connector test |

Components

| Name | Designation on PCB | Quantity |

|---|

| Control Board | RM120B-22 XK or BC886A097G51A | 1 |

| Power Board | RM162C-V2 or BC886A010G52 C | 1 |

| Power Module | BKO-NC1207 H84 Axes A2-D2-V2-8040 | 1 |