15.02.2026 by Viktor Siebert

Repair of a Mitsubishi Spindle Drive MDS-C1-SPX-220 with Alarm 32 Overcurrent After Repeated Overload

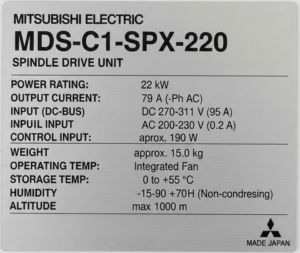

A company from the automotive industry contacted us due to an acute production downtime. The affected CNC machine was running in 24-hour operation and was completely blocked. Installed was a Mitsubishi MDS-C1-SPX-220 spindle drive with 22 kW power in a Mazak CNC machine.

Before the final failure, Alarm 50 Overload had occurred repeatedly. The machine was restarted several times, temporarily clearing the fault. However, after several minutes or hours, another shutdown occurred. Finally, Alarm 32 Overcurrent appeared permanently and the spindle module could no longer be started.

Due to long manufacturer delivery times and high replacement costs, the customer decided on an express repair. The unit was delivered by courier.

Incoming Inspection and Failure Analysis

After goods receipt, a standardized visual inspection was performed. No external mechanical damage was detected.

Electrical measurements revealed a short circuit in phase U at the motor output.

After disassembly, detailed inspection showed:

- Short circuit in the transistor module

- Defective driver components

- Damaged gate driver stage

- Aged electrolytic capacitors

- Contaminated heat sinks and air ducts

- Partially failed cooling fan

The damage pattern clearly indicated thermally induced failure caused by repeated overload.

Structured Repair Process

The repair followed standardized diagnostic and repair procedures:

- Complete disassembly

- Cleaning of all assemblies and heat sinks

- Industrial PCB washing

- Multi-hour drying process

- Replacement of the complete transistor module

- Replacement of all electrolytic capacitors

- Replacement of optocouplers and isolation amplifiers

- Replacement of the driver stage

- Replacement of the cooling fan

- Renewal of thermal compound

- Replacement of critical relays

We do not only replace defective components but also proactively replace known weak points to ensure long-term reliability.

After reassembly, the following tests were performed:

- Voltage calibration

- Current measurement

- Insulation testing

- Signal monitoring

- Multi-hour thermal stress test

- Output testing under load

The unit passed all tests without deviation.

Root Cause Analysis

The technical background of the failure was:

- Alarm 50 indicated continuous high current load

- The warning was repeatedly ignored

- The cooling fan was partially defective

- Reduced cooling caused thermal stress

- The power module failed and short circuited

- Alarm 32 Overcurrent was triggered

This is a typical failure scenario in older spindle modules operating continuously.

Preventive Recommendations

Our technician recommended:

- Scheduled fan replacement

- Annual cleaning of ventilation channels

- Inspection of heat sinks

- Regular insulation measurements

- Documentation of recurring warning messages

Preventive maintenance significantly increases the service life of 15-year-old power modules.

Result

The repair was completed within 48 hours. The unit was safely packaged and returned via courier.

After reinstallation, the customer reported stable operation in 24-hour production mode. The production downtime was minimized significantly.

Conclusion

The Mitsubishi MDS-C1-SPX-220 is a robust 22 kW spindle drive with modular construction.

The most common failure causes are:

- Thermal overload

- Power stage short circuits

- Voltage supply issues

- CNC communication errors

Structured diagnostics combined with preventive component replacement ensures reliable long-term operation and significantly reduces downtime.

To mentioned Mitsubishi Drive: Mitsubishi MDS-C1-SPX-220 Spindle Drive Unit

More details about our Mitsubishi repair services can be found here:

Mitsubishi drive Repair by Industrypart

📞 Feel free to contact us with any questions about your Mitsubishi drive technology.

Our expert team is happy to help!

Technical Specifications Mitsubishi MDS-C1-SPX-220 Spindle Drive

| Parameter | Value |

|---|

| Main Supply Voltage | DC 270–311 V |

| Output Current | 79 A AC |

| Power | 22 kW |

| Control Power | approx. 190 W |

| Weight | approx. 15 kg |

| Cooling | Integrated fan |

| Protection Functions | Overcurrent, overload, overtemperature, regeneration monitoring, watchdog |

| Type | Spindle Drive Unit |

| Manufacturer | Mitsubishi Electric |

| Application | CNC machine tools |

| Production Year | approx. 2005–2010 |

| Manual Reference | Mitsubishi MDS |

Operating Environment and Compatible Systems

The Mitsubishi MDS-C1-SPX-220 is used as a high-performance spindle drive in CNC machine tools. Typical applications include:

- Mazak machining centers

- Mitsubishi CNC control systems

- Vertical and horizontal milling machines

- Turning centers with integrated main spindle

Compatible with:

- Mitsubishi spindle motors with thermistor monitoring

- Mitsubishi MDS power supply units

- MDS series CNC bus communication systems

Functional Description

The MDS-C1-SPX-220 provides precise speed control of the main spindle.

Core functions include:

- Vector-based current control

- Speed feedback via encoder

- DC bus voltage monitoring

- Regenerative braking function

- Thermal motor monitoring

- Internal self-diagnostics with watchdog supervision

The power section is based on an IPM module controlling phases U, V, and W. A short circuit in the power stage typically results in Alarm 32.

Alarm Table Mitsubishi MDS-C1 Spindle Drive

| Code | Alarm Name English | Description / Possible Cause | Solution |

|---|

| 10 | Insufficient Voltage | DC bus voltage too low | Check power supply |

| 23 | Overspeed | Motor speed exceeded limit | Check encoder and parameters |

| 30 | Regeneration Error | Brake resistor overloaded | Check braking circuit |

| 32 | Power Stage Overcurrent | Short circuit phase U V W | Check IPM module |

| 37 | Parameter Error | Invalid motor parameters | Verify parameters Alarme _ Troubleshooting Mitsub… |

| 46 | Motor Overheat | Thermistor reports high temperature | Check motor cooling |

| 50 | Overload | Continuous operation above rated load | Check mechanical load |

| 52 | Power Stage Fault | Internal hardware fault | Inspect power board |

| 88 | Watchdog Error | CPU fault | Inspect control board |

| E7 | NC Communication Error | CNC bus connection interrupted | Check CNC cables |

Components Mitsubishi MDS-C1-SPX-220

| Assembly | Model Designation | Quantity | Function | Inspection Notes |

|---|

| Control Board | RK311C-21 or BN638A170G51 | 1 | Signal processing, bus communication, diagnostics | Visual and voltage inspection |

| Power Board | RL125B-SP-300 or BN638A163G51 | 1 | IPM control, current regulation | Check driver stage |

| Power Module | BKO-NC1208 H99 or B1-SP-220 | 1 | IPM module for phases U V W | Short circuit testing |

| DC Bus Capacitors | DC bus electrolytics | several | Voltage stabilization | ESR measurement |

| Fan Unit | Integrated axial fan | 1 | Cooling of heat sink | Airflow check |

| Regeneration Circuit | Internal brake resistor | 1 | Energy dissipation during deceleration | Resistance measurement |