02.10.2025 by Viktor Siebert

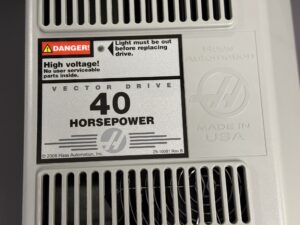

Repair Story: Haas 93-32-5558B 40HP Vector Drive with DC Bus Fault

Symptoms

A customer sent us a Haas 40HP Vector Drive (93-32-5558B) with a persistent fault that had worsened over several weeks.

When powering up the machine in the morning, the message “649 / 292 DC Bus Fault” regularly appeared. At first, it disappeared after just a few minutes, but over time the situation deteriorated to the point where the customer had to wait nearly an hour before production could resume.

For the customer, this was not only a scheduling problem but also a clear risk to production reliability.

Background

In discussions with the customer, it became clear that he had tried to bypass the problem by repeatedly switching the machine off and on. In some cases, the machine restarted, but in others the fault persisted.

However, this approach is highly dangerous: when the electrolytic capacitors in the DC bus lose stability, they can suddenly explode. In such cases, the enormous internal pressure literally tears the circuit board apart. This is accompanied by massive smoke development, charred traces, and sometimes even burned housing parts. In many cases, the device becomes completely irreparable.

Such a scenario would not only have caused downtime but also posed a significant safety risk on the shop floor.

Analysis

Our initial measurements quickly confirmed the suspicion: several electrolytic capacitors had lost most of their capacity. The DC bus could no longer be stabilized at 335 VDC, the voltage dropped under load, and the protective shutdown was triggered.

We also found thermally stressed semiconductors, including optocouplers, ISO amplifiers, and power transistors, which already showed signs of aging. Combined with degraded capacitors, these issues made a complete refurbishment essential.

Repair Process

To restore the vector drive to stable and safe operation, we carried out a comprehensive overhaul:

- Complete cleaning of the unit, including removal of oil and metallic particles.

- Replacement of DC bus capacitors with high-quality industrial-grade components rated for higher temperature and voltage.

- Renewal of thermally stressed semiconductors such as optocouplers, ISO amplifiers, and transistors.

- Preventive replacement of fans, as cooling issues are a frequent cause of secondary damage.

- Inspection of REGEN resistors for proper resistance values.

- Rework of critical solder joints to eliminate potential contact failures.

- Final insulation test to verify electrical safety.

Test Bench

After the repair, the device was tested extensively on our in-house test bench:

- Load cycle simulation from 0 to 100 % power.

- Thermal stress testing over several hours of continuous operation.

- DC bus monitoring, ensuring the target value of approx. 335 VDC under variable load.

- Simulation of fault conditions to validate protective functions.

The drive passed all tests and demonstrated stable and reliable behavior again.

Customer Benefits

The repair delivered decisive advantages for the customer:

- Production reliability: no more unpredictable waiting times or downtime.

- Cost savings: avoidance of an expensive replacement unit.

- Sustainability: reuse instead of scrapping conserving resources.

- Safe operation: no further risk of smoke, fire, or total failure caused by exploding capacitors.

Preventive Measures for the Customer

- Regular cleaning of heatsinks and airflow channels.

- Fan replacement every 3–5 years, even if no symptoms appear.

- Visual inspection of connectors for corrosion or loose contacts.

- Annual insulation testing of motor cables.

- Preventive capacitor replacement recommended after 7–10 years, depending on usage.

Conclusion

The Haas 40HP Vector Drive is a powerful yet sensitive core component. This case study clearly shows how dangerous it can be to ignore warning signs: aging electrolytic capacitors not only cause unstable DC bus voltage but may also explode, tearing the board into pieces and producing massive smoke.

Only through timely maintenance, preventive component replacement, and regular inspections can such catastrophic failures be avoided. Preventive action saves money, protects the machine, and ensures safe and reliable operation.

Learn more about our HAAS repair services here:

HAAS Drives and Motors

Regarding the mentioned unit:

Haas 93-32-5558B 40HP Vector Drive

📞 Questions or a defective unit?

Feel free to contact us directly – we provide fast, competent, and solution-oriented support.

Device Specifications:

| Feature | Value |

|---|

| Manufacturer | Haas Automation Inc. |

| Model | 93-32-5558B 40 HP Vector Drive |

| Power | 40 HP approx. 29.8 kW |

| Input | AC 3 × 230 V 50/60 Hz supply from machine transformer, phases A B C (e.g. RVD version at terminals 5 6 7) |

| DC Bus | approx. 320–340 VDC nominal ~335 VDC |

| Output to Spindle Motor | Three-phase PWM controlled AC |

| Servo Amp Supply | via common DC bus |

| Cooling | Forced-air, integrated fan |

| Protection Functions | Over-temperature, over-current, over-voltage, under-voltage, short circuit, REGEN monitoring |

| Control | Analog command signals from Maincon/Mocon, closed-loop vector control |

Application Environment & Compatible Devices

- Typical machines: CNC machining centers, lathes, milling machines from Haas.

- Compatible controls: Haas CNC (Classic Haas Control, NGC).

- Compatible motors: Haas spindle motors (20–40 HP).

- Application areas: Spindle drive, servo amplifier DC bus supply.

Functional Description

The Haas Vector Drive is the central power module for the spindle motor and servo axes. It:

- converts input AC to a stable DC bus (approx. 335 VDC),

- provides regulated power to the spindle (up to 40 HP),

- supplies servo amps with energy,

- uses REGEN resistors to dissipate braking energy,

- continuously monitors voltages, currents, temperatures,

- signals faults to the I/O PCB.

Thanks to closed-loop vector control, precise torque and speed behavior is ensured even under varying loads.

Alarms & Troubleshooting

| Code/Alarm | Description | Cause | Solution |

|---|

| 123 | Spindle Drive Fault | Short circuit or cable issue | Inspect cables/connectors, test drive |

| 160 | Low Incoming AC Line Voltage | Mains too low | Check supply, adjust transformer taps |

| 292 | High Voltage Power Supply Fault | DC bus issue | Measure bus, test drive |

| 648 | DC Bus Shorted | Bus or amp short | Test amplifiers individually |

| 647 | Regen Load Shorted | Faulty REGEN resistor | Measure resistance (6–12 Ohm) |

| 200 | Power Supply Overtemp | Fan/heatsink issue | Check/replace fan |

| 2038 | Vector Drive Overtemp | Cooling insufficient | Clean fan, replace |

| 4444 | Regen On Too Long | Excessive regeneration | Inspect mechanics, decel settings |

| 2040 | Spindle Amplifier Short Circuit | Defective amp | Test amp |

| Orientation Fault | Spindle orientation error | Unbalanced output | Check parameters & J3 connector |

Components

| Component | Function |

|---|

| Power board | IGBT stage, rectifier |

| Control board | Signal processing, interface |

| REGEN resistors | Absorb braking energy |

| Heatsink | Dissipates power losses |

| Fan unit | Forced-air cooling |

| DC bus capacitors | Energy storage |

| Connectors | Power, motor, control |