06.06.2025 by Viktor Siebert

Issue: Fanuc A06B-6096-H208 with IPM Alarm

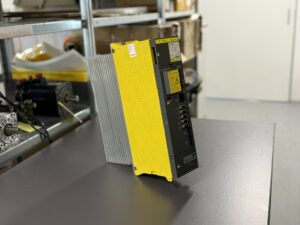

Today, a Fanuc A06B-6096-H208 Servo Amplifier Module leaves our facility – fully repaired and tested. The reported fault was Alarm 9, indicating an IPM (Intelligent Power Module) failure on the L or M axis.

According to the customer, the error only occurred once the system heated up – especially on warm days. He had already replaced all fans in the control cabinet, but not those inside the drive itself, as he lacked the technical knowledge.

Failed Spare Parts Procurement – Excessive Costs

The machine manufacturer could not offer a suitable replacement module – only a full exchange unit at a price well beyond any reasonable budget. Even direct contact with Fanuc led nowhere: Fanuc referred the customer back to the machine builder, citing that the module had been customized for the machine and could not be sold directly.

In need of a solution, the customer ordered the module from an online spare parts supplier – paying in advance. The promised delivery time was three days.

Delays, Excuses, and a Dubious Repair Offer

The promised 3-day delivery turned into more than two weeks – the unit never arrived. Fortunately, the faulty unit still worked intermittently in cooler conditions, so the customer could keep production going.

After two weeks, he began pressing the supplier for answers. He was repeatedly told of delays, shipping issues, and missing tracking information. After three weeks, he demanded a refund. The supplier then canceled the order, claiming the shipment had “disappeared,” and offered an alternative solution: to send in the unit for repair – supposedly at the same price as the exchange unit.

It became clear to the customer that this was a bottomless pit: no confirmation of a working repair, no testing assurance, and now a price higher than a normal exchange? He firmly demanded a refund.

Legal Help and a Valuable Lesson

More than a month passed before the customer finally received his money back – only after legal assistance. In hindsight, he called the situation a valuable lesson and decided to have the unit professionally evaluated instead.

Our Solution: Clear Process, Real Testing, Fast Turnaround

The customer contacted us to ask whether we could test and repair the unit. We explained our transparent process in detail:

- The unit is tested on our dedicated Fanuc test bench – both before and after repair.

- Our sales engineer provided a video showing a real test run.

- A firm quote with repair costs and lead time was provided in advance.

The customer decided to proceed with the repair – and just five days later, he received the repaired unit, reinstalled it, and restarted his machine. The fault was gone.

Performed Work

The following work was carried out as part of our standard repair process:

- Complete internal cleaning, especially heat sinks and air ducts

- Replacement of internal fans with high-quality, temperature-resistant industrial types

- Replacement of the defective IPM power module (L/M axis)

- Inspection of gate drivers and control boards

- Replacement of critical capacitors in the DC bus and power section

- Inspection and reworking of all solder joints as needed

- Functional testing on our Fanuc test stand, including thermal stress testing

- Simulation of real operating conditions over several hours

- Creation of a test protocol and documentation of all performed actions

To mentioned Fanuc Drive: Fanuc A06B-6096-H208 Servo Amplifier Module

More details about our Fanuc repair services can be found here:

Fanuc drive Repair by Industrypart

📞 Feel free to contact us with any questions about your Fanuc drive technology.

Our expert team is happy to help

Device Overview: Fanuc A06B-6096-H208

| Feature | Description |

|---|

| Model | A06B-6096-H208 |

| Type | α-Series Servo Amplifier Module |

| Input Voltage | 283–325 V DC |

| Output Voltage | max. 230 V AC |

| Rated Power | 9.5 kW |

| Output Current | 18.7 A (L-axis and M-axis) |

| Reference Manual | B-65162 |

| Manufacturer | FANUC LTD, Japan |

| Typical Motor Types | FANUC α-Series AC Servo Motors (e.g. α12, α22 etc.) |

Functional Overview

This amplifier module converts regulated DC bus voltage (283–325 V) into controlled, sinusoidal AC voltage to drive Fanuc AC servo motors. It precisely controls torque, speed, and position, and communicates via control signals with FANUC CNC systems (e.g., 0i, 16i, 18i series).

Fanuc A06B-6096-H208 Alarm Table

| Alarm Code | Description | Solution |

|---|

| AL01 | Overcurrent fault | Check motor current, inspect load mechanics, check encoder if necessary |

| AL02 | DC bus voltage too high | Check regenerative load, inspect brake resistor and mains voltage |

| AL03 | DC bus voltage too low | Inspect power supply, check input filters |

| AL04 | Amplifier overtemperature | Check cooling system, clean or replace fans |

| AL05 | Feedback/encoder signal error | Check encoder cable and connectors, replace encoder if needed |

| AL06 | Phase sequence error | Verify correct phase cable sequence |

| AL07 | Internal amplifier fault | Inspect amplifier PCB or power stage, replacement may be needed |

| AL08 | Overload / sustained overcurrent | Check load profile, avoid long-term overload |

| AL09 | Communication error with CNC | Inspect CNC communication cables and connections |