08.02.2026 by Viktor Siebert

Repair of a FANUC A06B-6079-H206 Servo Amplifier Module with Permanent Alarm 9

Initial situation and fault description.

The FANUC A06B-6079-H206 Servo Amplifier Module was delivered to us with a clear and critical fault condition. Immediately after power-up, the 7-segment display showed a permanent alarm “9”. The alarm could not be reset and remained active at all times. In the machine, this condition caused a complete shutdown of the affected axes, as the system consistently refused to enable the power stage.

Alarm 9 on FANUC Alpha servo amplifiers indicates an internal IPM fault. The drive detects an impermissible condition inside the power stage and shuts down instantly to protect the hardware. From experience, this is rarely a sporadic issue. In most cases, it is the result of a gradually developing internal defect.

Initial diagnosis and incoming inspection

After receipt, the module was first inspected visually. No mechanical damage, no visible burn marks, and no loose screws on the DC-link bus bars were detected. The unit was then connected to our test bench for an initial electrical check. Even when powered up without connected motors, the fault was immediately reproducible. Alarm 9 appeared directly during initialization.

At this stage, external causes such as motor short circuits, cable faults, or mechanical axis blockage could be ruled out. The root cause had to be located inside the power stage or its monitoring circuitry.

Power stage fault analysis

Detailed diagnostics revealed abnormalities in the power section of the module. The internal protection mechanisms had detected a fault condition typically associated with a damaged power stage. Such damage usually does not occur suddenly. Common contributing factors include long-term thermal stress, contaminated or aged cooling fans, increased contact resistance in power paths, or repeated current peaks caused by high dynamic axis loads.

In dual-axis modules like the A06B-6079-H206, thermal weaknesses often affect both channels, even if the fault initially becomes visible on only one axis. For this reason, we do not follow a minimal repair approach. Instead, we apply a consistent preventive repair strategy.

Preventive repair process

Once the fault was clearly identified, the module was completely disassembled. The power unit was removed, thoroughly cleaned, and subjected to an in-depth visual and functional inspection. The goal is not only to eliminate the immediate defect, but also to assess all surrounding components that have been exposed to the same stress conditions.

As part of the preventive repair, all thermally critical areas were checked. Cooling components and airflow paths were cleaned and evaluated, as insufficient cooling is one of the primary causes of IPM-related failures. In addition, all relevant power connections were inspected to avoid future contact resistance, overheating, and recurring failures.

Quality assurance is a key part of the process. The module was not only tested statically but operated under realistic conditions on our test bench. Both axes were driven individually, load changes were simulated, and temperature behavior was monitored over an extended period. Only after stable operation without recurrence of alarm 9 was the unit approved for return.

Test procedure and quality assurance

Final testing was carried out using a stabilized DC-link supply of approximately 300 V, corresponding to typical operation with a FANUC power supply module. The control voltage was monitored continuously to ensure stable reference conditions without undervoltage or regulation issues.

The following criteria were verified during testing: clean startup without alarms, stable axis enable, normal current behavior on both channels, and thermally stable operation throughout the entire test duration. Only after meeting all these criteria is a module considered successfully repaired.

To mentioned Fanuc Drive: Fanuc A06B-6079-H206 Servo Drive Unit

More details about our Fanuc repair services can be found here:

Fanuc drive Repair by Industrypart

📞 Feel free to contact us with any questions about your Fanuc drive technology.

Our expert team is happy to help!

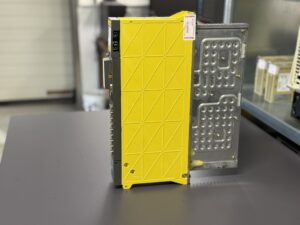

FANUC A06B-6079-H206 Servo Amplifier Module

Device overview

| Parameter | Specification |

|---|

| Manufacturer | FANUC |

| Device type | Servo Amplifier Module |

| Model | A06B-6079-H206 |

| Series | Alpha Series |

| Design | Dual-axis servo amplifier (Twin Module) |

| Type designation | SVM2-40/40 |

| Application | CNC machine tools |

Electrical specifications

| Parameter | Value |

|---|

| DC-link input voltage | 283–325 V DC |

| Power supply | Via FANUC Power Supply Module (PSM) |

| Control voltage | 24 V DC |

| Rated current per axis | approx. 12,5 A |

| Number of axes | 2 (L-axis / M-axis) |

| Motor output voltage | up to approx. 230 V AC |

| Protection functions | Current, voltage, and temperature monitoring |

Interfaces and communication

| Parameter | Description |

|---|

| Control interface | Type B |

| Communication | System-dependent, e.g. FSSB |

| Axis assignment | CNC parameter-based |

| Status indication | 7-segment LED (READY / alarm code) |

Cooling and mechanical design

| Parameter | Description |

|---|

| Cooling concept | External heat sink |

| Fan | Integrated fan with speed monitoring |

| Mounting | Control cabinet, backplane mounting |

| Heat dissipation | Aluminum heat sink |

Typical alarm and fault codes (selection)

| Code | Description | Typical cause |

|---|

| 9 | IPM alarm | Power stage fault |

| 8 | Axis overcurrent | Short circuit, motor fault, load peak |

| 1 | DC-link overcurrent | Internal power fault |

| 2 | Control voltage low | Unstable 24 V supply |

| A / b / c | Communication fault | FSSB or connector issues |

| L / M | Axis-related overcurrent | Mechanical blockage or motor issue |

Typical operating environment

| Area | Description |

|---|

| Machines | CNC lathes, machining centers |

| Motors | FANUC Alpha servo motors |

| Load profile | High dynamics, frequent acceleration changes |

| Environment | Industrial conditions with thermal stress |

Repair-relevant assemblies

| Assembly | Function | Notes |

|---|

| Power stage | Motor current generation | Thermally highly stressed |

| IPM module | Power switching | Critical for alarm 9 |

| DC-link section | Energy supply | Check for contact resistance |

| Fan assembly | Cooling | Common failure cause |

| Control board | Monitoring and communication | Heat-sensitive |

Preventive maintenance recommendations

| Measure | Benefit |

|---|

| Heat sink cleaning | Prevention of heat accumulation |

| Fan inspection | Protection of power stage |

| Power connection checks | Reduced contact resistance |

| Dual-axis load testing | Early detection of thermal issues |

| Extended load testing | Long-term operational reliability |