21.04.2025 by Viktor Siebert

Introduction and Special Features of the Yaskawa XtraDrive

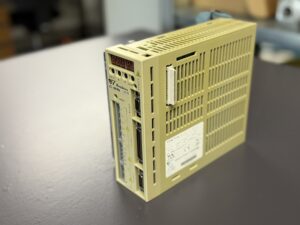

We recently repaired a Yaskawa XtraDrive XD-08-MN. These units are relatively rare and specifically designed by Yaskawa for particular applications, making replacement or retrofitting quite challenging.

Fault Description: Encoder Connection Failure

The issue was particularly intriguing: the drive suddenly stopped recognizing the connected motor. Recognition is achieved through the encoder cable, enabling the servo amplifier to constantly monitor which motor is connected and its status. As soon as the connection to the motor is lost, the device immediately displays an encoder error alarm on the small LED display.

Diagnosis and Root Cause

To determine the cause of this issue, we conducted various tests, specifically heating and cooling the servo pack. While cooling did not trigger any errors, heating immediately caused the error message to reappear. The small SMD electrolytic capacitors on the control board were notably affected by heating. After desoldering these capacitors, we could clearly detect the distinctive smell of leaking electrolyte. The electrolyte had corroded the PCB traces, resulting in a short circuit. Heating reduced resistance further, exacerbating the short circuit.

Role of Electrolytic Capacitors

Electrolytic capacitors are commonly the cause of failures in power supplies and control units. Their primary function is to maintain stable and noise-free operating voltages by smoothing and stabilizing voltages. If these capacitors fail or short-circuit, subsequent components like integrated circuits (ICs) can be affected. In this case, it resulted in a loss of encoder connectivity.

Customer Misdiagnosis

Initially, the customer incorrectly assumed the fault lay with the motor or encoder itself and unnecessarily replaced the motor.

Repair and Preventative Measures

We ultimately replaced the defective capacitors, thoroughly cleaned and repaired the PCB traces, and coated the repaired areas with special protective lacquer. Additionally, the following preventive maintenance measures were undertaken:

- Overhaul of the power supply

- Replacement of output transistors

- Replacement of all electrolytic capacitors

- Replacement of optoelectronic components

- Cleaning of the device in a specialized cleaning system using appropriate agents, followed by careful drying.

Final Testing and Results

After completing the repair, the device was tested under load with the appropriate motor and re-parameterized. Since then, it has been operating flawlessly at the customer’s facility.

Conclusion

Thorough diagnosis and preventive maintenance are critical. They ensure equipment can function reliably for many years, significantly contributing to sustainability.

Technical Specifications and Operation

Yaskawa XtraDrive XD-08-MN

- Power rating: approx. 0.75 kW

- Supply voltage: 230 V (single-phase)

- Encoder interface: Serial absolute encoder

- Functions: Position control, torque control, precise motor control

Yaskawa Servo Motor SGMGH-05ACA2C

- Rated power: 0.45 kW

- Rated torque: 2.8 Nm at 1500 RPM

- Peak torque: approx. 9 Nm

- Encoder: 17-bit serial absolute encoder

The XtraDrive XD-08-MN servo amplifier works particularly reliably and precisely in combination with the SGMGH-05ACA2C servo motor. It controls the motor with high accuracy, which is crucial for exact positioning and optimal stability in CNC applications.

For further details such as pricing and delivery times regarding the

Yaskawa XtraDrive XD-08-MN

Yaskawa Servomotor SGMGH-05ACA2C

For more information about our Yaskawa repairs, please click here.

📞 Please feel free to contact us with any questions regarding your Yaskawa drive technology. Our experienced team is always ready to assist you.