16.10.2025 by Viktor Siebert

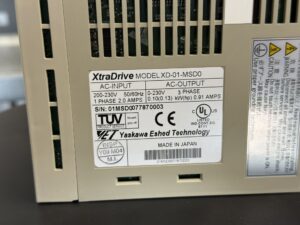

Dangerous Fakes. When Supposed XtraDrives Turn into a Risk Yaskawa XtraDrive XD-01-MSD0 case

A customer purchased what he thought were genuine XtraDrive XD-01-MSD0 drives from an Asian seller. The price was high, the trust was strong, and the units looked authentic.

However, the drives were never tested upon arrival. They remained in storage for months until a machine failure revealed the truth: the purchased units were fake conversions of 100-watt Yaskawa servos from a different series.

Externally identical and connector-compatible, internally manipulated but useless. The control boards had been tampered with, yet the drives never functioned.

The result: total failure, high financial loss, no refund possible as the eBay return period had expired.

Such cases are increasingly common. Many sellers register accounts in Europe while shipping from China. Customers feel safe when devices look “new”

but often they are just cosmetically refurbished or plain counterfeits.

Our approach:

- Opened and analyzed the fake units: immediately visible mismatches in power and control sections.

- Created documentation with photos for the customer.

- Received the customer’s original defective drives, which we repaired.

- Preventive replacement of critical components (capacitors, optocouplers, power modules).

- Tested on original test bench with thermal load monitoring.

Testing procedures:

- 100% load endurance test for several hours.

- Oscilloscope monitoring of signals.

- Thermal monitoring of heatsink and PSU.

In the end, the repaired genuine units were returned to the customer fully functional, documented, and verified.

Had the fakes been used longer, the customer would have faced extended downtime, machine shutdown, and massive follow-up costs.

Preventive Measures for the Customer

- Test devices immediately upon delivery, do not store them untested.

- Perform regular cleaning and inspection.

- Replace fans and seals proactively.

- Conduct insulation testing on motors and cabling.

- Regularly check connectors as vibration can cause wear.

- Maintenance intervals: inspection every 12–18 months, preventive overhaul every 3–5 years.

Conclusion

This case clearly shows: cheap counterfeits are a dangerous trap.

Only tested repairs and original parts ensure operational reliability. Preventive maintenance not only saves costs but also protects the entire machine from unexpected breakdowns.

For further details such as pricing and delivery times regarding the Yaskawa XtraDrive XD-01-MSD0

For more information about our Yaskawa repairs, please click here.

📞 Please feel free to contact us with any questions regarding your Yaskawa drive technology. Our experienced team is always ready to assist you.

Technical Profile:

| Feature | Value |

|---|

| Model | Yaskawa XtraDrive XD-01-MSD0 |

| Manufacturer | YET (Yaskawa Eshed Technology), Made in Japan |

| Input Voltage | 200–230 V AC, 50/60 Hz |

| Input Current | 1-Phase, 2.0 A |

| Output Voltage | 200–230 V AC |

| Output Current | 0.91 A |

| Output Power | 0.10 kW (approx. 0.13 HP) |

| Output Phases | 3-Phase |

| Weight | approx. 1.2–1.5 kg (estimated) |

| Dimensions | approx. 130 × 55 × 160 mm (200V series according to manual) |

| Cooling | Convection via heatsink |

| Control | PROFIBUS, Analog, Pulse-Train, integrated positioner |

| Encoder Interface | A/B/Z incremental, serial 13–17 bit |

| Protection Functions | Overcurrent, over/undervoltage, overload, regeneration error, overspeed, overheating, encoder error |

Application Environment & Compatible Devices

- Typical machines: CNC machines, automation systems, machine tools, packaging and assembly lines.

- Controllers: PROFIBUS-based systems (e.g., Siemens S7), analog controllers, pulse-train inputs.

- Compatible motors: Servomotors up to 0.1 kW rated power, especially for small axes such as feeders, handling, or positioning.

- Environment: 0–55 °C operating temperature, < 90% RH, no condensation

Functional Description

The XtraDrive XD-01-MSD0 is a compact servo drive for small axis motors up to 0.1 kW. Key features:

- High-precision servo control through proprietary algorithms (e.g., NCT and OCA for vibration suppression).

- PROFIBUS-DP communication, including cyclic diagnostics.

- Integrated positioner with programmable motion profiles.

- Protection mechanisms: overcurrent, overvoltage, undervoltage, overload, regeneration, overheating.

- Digital I/Os (7 inputs, 7 outputs), 2 analog inputs and outputs.

- Speed range: 1–6000 rpm

Alarm Messages & Troubleshooting

| Code | Error Description | Cause | Solution |

|---|

| A.02 | Parameter Breakdown | Corrupt or invalid parameter values | Reload parameters, reinitialize |

| A.05 | Servo/Motor Combination Error | Wrong motor connected | Check motor type, connect correct motor |

| A.10 | Overcurrent/Heatsink Overheat | Short circuit, blockage or poor cooling | Check load, clean heatsink, verify fan |

| A.30 | Regeneration Error | Defective or overloaded resistor | Test/replace resistor |

| A.32 | Regeneration Overload | Excessive feedback energy | Adjust parameters, reduce load |

| A.40 | Overvoltage | Supply voltage too high | Check power supply |

| A.41 | Undervoltage | Voltage drop or unstable network | Check supply and cabling |

| A.51 | Overspeed | Motor overspeed detected | Adjust parameters, check encoder |

| A.71 | Overload (High Load) | Continuous high axis load | Inspect mechanics, dimension motor correctly |

| A.B1 | Reference Speed Input Error | Analog input failure | Inspect input, test source |

Components

| Module | Function |

|---|

| Power Board | Converts input voltage to motor power |

| Control Board | Signal processing, PROFIBUS, parameter management |

| Heatsink | Dissipates heat from power modules |

| Power Supply Module | Supplies electronics |

| Connectors | Motor, encoder, PROFIBUS, I/Os |

| Housing | Protection, insulation, airflow |