18.09.2025 by Viktor Siebert

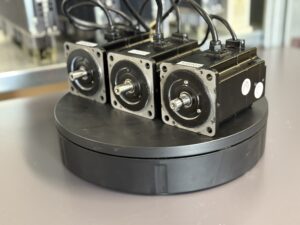

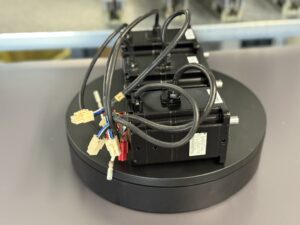

Maintenance instead of retrofit three Yaskawa SGMPH-04A1A-YR52 AC servo motors successfully overhauled!

We received three of these motors from a Yaskawa application.

The customer had been sending defective units for exchange to the OEM. But recently, he was told the motors were discontinued, and the only solution was a retrofit: replacing motors, drives, and controls, a cost comparable to replacing the entire machine.

He was not willing to accept this and turned to us.

Our analysis revealed:

- Brakes still within tolerance

- Encoders faulty, delivering unreliable signals

We performed a complete overhaul:

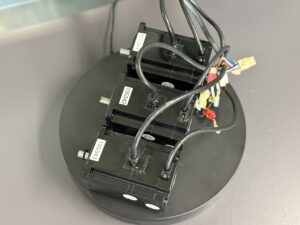

- Bearing replacement

- Seal and connector renewal

- Thorough cleaning incl. emulsion removal

- Oven drying for moisture elimination

- Encoder replacement (UTSAH-B16DC-E) with calibration

- Signal testing and insulation measurement

On the test bench, all motors passed under load:

- Encoder signal quality

- Torque and speed tests

- Brake holding force

- Insulation resistance

The customer could continue operating his machines without retrofit saving significant costs.

Causes of Encoder or Motor Failures

- Aging of encoder electronics

- Contamination with oil, dust, or emulsions

- Bearing wear under continuous load

- Cable and connector fatigue

- Overheating from insufficient cooling

Preventive Tips for Customers

- Inspect cables and connectors regularly

- Monitor encoder signals during maintenance cycles

- Replace bearings preventively after 20,000–30,000 hours

- Keep the environment clean from oil and dust

- Test brake performance, especially in vertical axes

Information about the mentioned Servomotor and other components:

Yaskawa SGMPH-04A1A-YR52 Servo Motor

More information about our Yaskawa repairs can be found here.

📞 Feel free to contact us if you have any questions regarding your Yaskawa drive tech

Device Specifications

| Parameter | Value |

|---|

| Model | Yaskawa SGMPH-04A1A-YR52 AC Servo Motor |

| Voltage | 400 V AC |

| Rated Current | 2.6 A |

| Rated Power | approx. 400 W |

| Rated Torque | approx. 1.27 Nm |

| Max. Speed | 3000 rpm |

| Weight | approx. 4.5–5.0 kg (estimated, similar models) |

| Protection Class | IP65 (standard for Sigma-II motors) |

| Insulation Class | B |

| Encoder | Yaskawa UTSAH-B16DC-E (absolute, high resolution) |

| Brake | OGURA CLUTCH MCDB20Y-15 |

| Cooling | Natural convection |

| Frame Size | Medium, compact |

| Manufacturer | Yaskawa Electric Corporation, Japan |

Application Environment & Compatible Devices

This motor is used in CNC machines, automation systems, and assembly equipment.

Compatible with Yaskawa Sigma II Servopacks (SGDH series) in the 400 W range.

Typical applications: feed drives, positioning axes, and precision automation.

Functional Description

The SGMPH-04A1A-YR52 is a compact AC servo motor providing high dynamics and precise torque control.

Equipped with the UTSAH-B16DC-E absolute encoder, it delivers reliable position feedback for CNC precision.

The integrated OGURA MCDB20Y-15 brake ensures secure holding at power-off, crucial for vertical axes.

Alarm Messages & Troubleshooting

Based on Yaskawa Sigma II/SGDH manuals

| Code | Error Description | Cause | Solution |

|---|

| A.02 | Parameter Breakdown | Faulty EEPROM data | Check/replace drive |

| A.03 | Main Circuit Encoder Error | Abnormal detection in power circuit | Inspect encoder/cable |

| A.05 | Servo/Motor Combination Error | Wrong motor-drive match | Verify compatibility |

| A.10 | Overcurrent / Overheating | IGBT short or overload | Improve cooling, replace parts |

| A.30 | Regeneration Error | Faulty regen circuit | Check resistor |

| A.40 | Overvoltage | DC voltage too high | Inspect supply |

| A.41 | Undervoltage | DC voltage too low | Verify mains |

| A.51 | Overspeed | Motor speed too high | Adjust parameters |

| A.71 | Overload (short-term) | Excessive load | Check mechanics, overhaul |

| A.82 | Encoder Checksum Error | Encoder memory checksum abnormal | Replace encoder |

| A.C9 | Encoder Communication Error | No communication motor ↔ drive | Replace cable/encoder |

Components

| Component | Description |

|---|

| Rotor | Laminated core with permanent magnets |

| Stator | Three-phase windings |

| Encoder | UTSAH-B16DC-E absolute encoder |

| Brake | MCDB20Y-15 holding brake |

| Bearings | Precision ball bearings |

| Housing | Black painted aluminum |

| Seals | Shaft seals, IP65 protection |

| Connectors | Power/encoder plugs |

| Cooling | Convection |