12.12.2025 by Viktor Siebert

Repair of a Yaskawa SGDS-08A01A Servopack with Alarm A.030

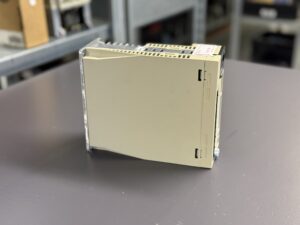

When the SGDS-08A01A arrived at our facility the failure was already clearly described. The customer reported that the unit triggered alarm A.030 immediately after power on. In practice, this alarm points to a malfunction in the main circuit detection, more precisely an incorrect feedback of the internal DC bus monitoring. Such faults often originate from ageing phenomena, thermal load or external influences. It was clear that the device needed a comprehensive diagnostic procedure.

After the initial inspection we observed typical signs of long term operation. Even though the exterior was in good condition, internal areas showed dust accumulation and slight discoloration near the DC bus components. Such patterns often indicate elevated thermal stress. We removed the entire power section and performed an isolated analysis. The results showed that the shunt measurement circuit responsible for DC bus supervision no longer behaved reliably. The amplifier stage was unstable and the reference values drifted, which the firmware correctly recognized as alarm A.030.

In cases like this, replacing only one component is not sufficient. Thermal load often affects surrounding circuit elements and leads to secondary defects. We therefore disassembled the complete power stage, cleaned the PCB using a controlled wet process and dried the assembly in a technical oven. An ESR analysis of all electrolytic capacitors followed. Several showed increased ESR values which is common for devices of this age and should always be replaced preventively.

The gate driver circuits and optocouplers were also tested. Some of them showed reduced transfer characteristics, which over time can cause control inaccuracies. To ensure long term stability, we replaced all critical components within the signal and power interface. We then recalibrated the thermal monitoring path because faults in the main circuit detection often affect heat response characteristics.

After completing the hardware overhaul the Servopack entered the test phase. We operated the unit on our Sigma II test bench under multiple load scenarios. Acceleration, deceleration, torque peaks and regeneration processes were simulated. The device performed consistently without any irregularities and the DC bus monitoring values were precise again. Thermal cycles verified that the unit remained stable even under heavy load.

The customer received the Servopack with documentation and a recommendation to improve the airflow inside the control cabinet. Many of these failures originate from elevated ambient temperatures acting over long periods. Through preventive replacement, deep cleaning and structured testing we restored full functionality. The customer was able to resume production without further delays.

Preventive Measures for the Customer

• Regular cleaning of the control cabinet

• Monitoring temperature and ensuring adequate ventilation

• Replacement of DC bus capacitors every 8 to 10 years

• Inspection of fans and airflow components

• Ensuring proper grounding

• Avoid routing power and signal cables in parallel

• Running periodic test cycles to verify encoder performance

Conclusion

Alarm A.030 highlights the importance of precise DC bus monitoring in modern servo amplifiers. With a thorough overhaul and preventive maintenance the lifetime of the equipment can be significantly extended while increasing machine availability.

For further details such as pricing and delivery times regarding the Yaskawa SGDS-08A01A Servopack

For more information about our Yaskawa repairs, please click here.

📞 Please feel free to contact us with any questions regarding your Yaskawa drive technology. Our experienced team is always ready to assist you.

Technical Profile:

| Parameter | Value |

|---|

| Model | SGDS-08A01A |

| Series | Sigma III Servopack |

| AC input | Single phase 200 to 230 V AC, 50/60 Hz |

| Input current | 8.8 A |

| AC output | Three phase 0 to 230 V, 0 to 300 Hz |

| Output power | 0.75 kW |

| Motor rated current | 5.5 A |

| Operating temperature | 0 to 55 °C |

| Cooling | Convection cooling and internal airflow |

| Control type | AC servo controller for torque, speed and position control |

| Manufacturer | Yaskawa Electric, Japan |

| Protection class | IP1X |

| Compatible motors | Yaskawa Sigma III AC servo motors, 200 V class |

Operating Environment and Compatible Equipment

The SGDS-08A01A Servopack is part of the Sigma III series and is widely used in machine tools, handling systems, CNC gantry applications, packaging machines and automated production equipment.

It operates with servo motors of the SGM(H)/(G)/(P) family in the performance range up to 750 watts. Feedback is provided through incremental or absolute encoder systems from the Sigma II generation.

Typical controllers

• Yaskawa MP-controller

• Siemens, Fanuc, Bosch and other CNC systems through optional interfaces

• Digital operators such as JUSP-OP03A or SigmaWin+

Environment

• Control cabinets with defined airflow

• Low vibration conditions

• Minimal exposure to dust, oil mist or aggressive contaminants

• Proper grounding and EMC compliant cable routing

Functional Description

The SGDS-08A01A provides complete servo control for a 0.75 kW motor. It regulates torque, speed and position and implements various protective and diagnostic features.

Core functions

• Power amplifier for driving a three phase AC servo motor

• Torque, speed and position control loops

• Encoder feedback and monitoring

• Protection functions for overcurrent, overtemperature, overvoltage and configuration errors

• Regeneration control for internal or external braking resistors

• Diagnostic interface with alarm codes, LED display and serial communication

Alarm A.030 indicates a malfunction in the main circuit detector. This fault is typically linked to incorrect detection of the DC bus condition, often caused by defective shunt measurement circuits, aged amplifiers, damaged conductor paths or thermal stress in the power section.

Alarm Messages and Troubleshooting

| Code | Description | Cause | Solution |

|---|

| A.020 | Parameter checksum error | Corrupted EEPROM data | Reset parameters, check EEPROM |

| A.030 | Main circuit detector error | DC-bus detection malfunction | Inspect power stage and detection circuit |

| A.040 | Parameter setting error | Parameter outside the valid range | Correct parameter values |

| A.410 | Undervoltage | DC-bus voltage too low | Check input supply and rectifier stage |

| A.400 | Overvoltage | DC-bus voltage too high | Check regeneration path and braking resistor |

| A.710 | Overload high load | Overload for several seconds | Check mechanical load and motor current |

| A.720 | Overload low load | Continuous overload | Inspect load characteristics, mechanics and lubrication |

| A.810 | Encoder backup error | Backup supply loss | Check wiring and encoder power |

| A.C10 | Servo overrun | Servo system out of control | Inspect control loop and feedback integrity |

| CPF00 | Operator transmission error | Communication failure | Check cable and operator module |

Based on the SGDS alarm list.

Components

| Component | Description | Function |

|---|

| Power module | IGBT stage | Drives the motor |

| DC bus section | Electrolytic capacitors | Smooths DC supply |

| Shunt detection circuit | Shunts and amplifiers | Measures current and voltage |

| Control board | CPU, RAM, EEPROM | Regulation and communication |

| Gate drivers | Optocouplers and drivers | Switch control for IGBTs |

| Power supply section | AC to DC conversion | Supplies electronics |

| Fan | Internal cooling | Heat management |