16.09.2025 by Viktor Siebert

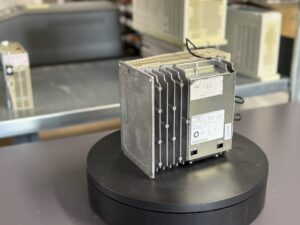

Yaskawa SGDH-15DE AC Servopack + Technical Review

A furniture manufacturer contacted us with an urgent problem: The Yaskawa SGDH-15DE Servopack in his production line failed sporadically with error code A.b1. The failure occurred irregularly and led to machine downtime, a major challenge, as a critical order for an international customer was being processed at the time.

To avoid production losses, we immediately decided on a pragmatic solution: We provided the customer with an identical replacement unit from our stock. Before shipment, we programmed the replacement Servopack with the parameters provided by the customer. This allowed the unit to be put into operation immediately after installation, without additional adjustments. The customer was able to continue production without interruption.

One week later, we received the defective unit for analysis and repair. The fault description confirmed the sporadic A.b1 Reference Speed Input Error, pointing to a defect in the A/D converter of the control section.

Repair process:

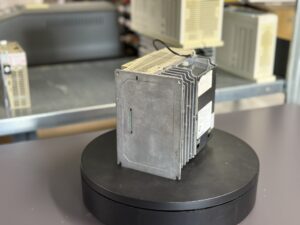

- Incoming inspection and visual check for dust, oil, and damage.

- Complete cleaning of the device with compressed air and special cleaners.

- Electrical tests to identify the faulty A/D channel.

- Preventive replacement of critical components such as capacitors, relays, connectors, and the fan.

- Functional and load testing on our test bench under realistic operating conditions.

- Complete documentation of all steps and measured values.

After the successful repair, the customer decided to keep the unit as an additional spare. This not only solved the acute problem but also significantly improved operational security for future production orders.

Preventive Measures for the Customer

- Regular cleaning of ventilation openings and heat sinks

- Replace fans every 3–5 years

- Perform insulation tests on motors and cables

- Inspect seals against dust and oil mist

- Secure parameter backups regularly

Conclusion

The SGDH-15DE case demonstrates the importance of keeping spare units and taking preventive maintenance seriously. By quickly providing a pre-programmed replacement, the customer was able to complete his order without delays. The thorough repair of the defective unit not only extended its lifetime but also provided the customer with an additional spare device for future use.

Further information such as price and delivery time for:

Yaskawa SGDH-15DE AC Servopack

More details about our Yaskawa repair expertise can be found here: Yaskawa SIGMA II repairs by Industrypart

Similar models we regularly repair:

SGDH-15DE-OY

SGDH-15AE-OY (200V Type)

Technical specifications Yaskawa SGDH-15DE

| Parameter | Value |

|---|

| Model | SGDH-15DE |

| Series | Sigma II |

| Manufacturer | Yaskawa Electric Corporation |

| AC Input | 3-phase, 380–480 V, 50/60 Hz, 4.8 A |

| AC Output | 3-phase, 0–480 V, 0–300 Hz, 5.4 A |

| Output Power | 1.5 kW |

| Protection Class | IP1X |

| Ambient Temperature | 0–55 °C |

| Origin | Made in Japan |

Application & Compatible Devices

The Yaskawa SGDH-15DE Servopack is part of the Sigma-II series and is commonly used in CNC machines, machining centers, as well as wood and metal processing equipment. It is designed for precise positioning and drive tasks and is compatible with Yaskawa Sigma-II servo motors such as the SGMGH and SGMG series. It is often found in machines from different manufacturers .

Functional Description

The SGDH-15DE Servopack controls and powers servo motors. It converts three-phase input voltage into regulated output signals, precisely controlling speed, torque, and position, while also protecting the motor against overload and malfunctions. Its built-in fault diagnostics enable fast troubleshooting and minimize downtime.

Alarm Messages & Troubleshooting

| Alarm | Error Description | Cause | Solution |

|---|

| A.02 | Parameter breakdown | EEPROM failure | Replace control board |

| A.05 | Motor/Amplifier mismatch | Wrong motor selection | Use correct motor |

| A.10 | Overcurrent / Heat sink overheated | IGBT fault or insufficient cooling | Inspect heat sink, replace fan |

| A.30 | Regeneration error | Faulty resistor | Inspect/replace resistor |

| A.32 | Regeneration overload | Excessive energy | Use higher-rated resistor |

| A.40 | Overvoltage | Line voltage too high | Check mains, use surge protection |

| A.41 | Undervoltage | Line voltage too low | Stabilize supply |

| A.71 | Overload (high load) | Continuous overload | Inspect load |

| A.b1 | Reference speed input error | Faulty A/D converter | Replace control board |

| A.C1 | Servo overrun | Control failure | Optimize parameters |

Components

| Component | Description |

|---|

| Power module | IGBT-based power stage |

| Control board | Controls current, torque, position |

| Power supply section | Rectifier and DC link |

| Fan unit | Heat sink cooling |

| Regeneration resistor (external) | Energy absorption during braking |