21.06.2025 by Viktor Siebert

Partnership for a Sustainable Industry: Repair Instead of Retrofit Yaskawa DR2-04ACP

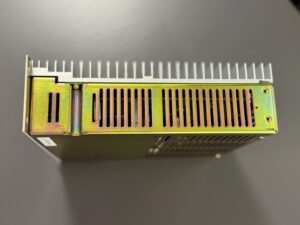

A well-known customer from the Swiss pharmaceutical sector approached us with a special request: The Yaskawa DR2-04ACP Servopack series had been discontinued by the manufacturer, and a retrofit was recommended — meaning a complete replacement of the drive electronics. A solution that is not only expensive but also questionable in terms of sustainability, as retrofits often involve full conversions or even purchasing a new machine.

Sustainability as a Practiced Standard

The customer, a certified company with the highest environmental standards, wanted to take a different path — one that is sustainable, efficient, and resource-conscious. Through a recommendation, they came across industrypart GmbH.

What they found with us was not only precise repair work, but also a structured and standardized system that integrated seamlessly into their own processes. The collaboration was smooth from the start: Devices are shipped to us, repairs are carried out on a flat-rate basis, and returned on time — the technician on-site only needs to plug it in.

What We Repair on the DR2-04ACP

The Yaskawa DR2 series is technically robust, but after years of operation, recurring faults tend to appear — issues we know from hundreds of repairs:

| Common Faults | Root Cause |

|---|

| Overcurrent (Alarm A.10) | Faulty output stage, short circuit in IGBT module |

| Blown Fuse (A.20) | Internal fuse failure, often caused by short circuit |

| Regeneration Error (A.30) | Problems with internal or external brake circuit |

| Encoder errors (A.00–A.85) | Encoder faults or cable issues |

| Overload / Overtemperature | Clogged heatsinks, faulty power components |

Step-by-Step Repair Process

- Initial Testing & Fault Diagnosis

Upon arrival, we perform a full visual and functional test using load simulation.

- Component Replacement

Depending on the diagnosis, we replace:

- IGBT modules and driver stages

- Internal fuses

- Capacitors (when aged or out of spec)

- Cooling fans and thermal sensors

- Faulty connectors or encoder interfaces

- Cleaning & Rework

The unit is completely cleaned, PCBs are optically and electrically inspected, and cold solder joints are reworked.

- Final Testing & Documentation

The repaired unit undergoes a full load test. All output voltages, currents, and status signals are logged. Encoder functionality is separately verified.

- Packaging & Return

The unit is securely packaged in anti-static material, labeled, documented, and returned ready for installation.

Repairing Instead of Replacing – Practicing Responsibility

This story shows how industrial maintenance can be done right: ecologically sound, economically efficient, and logistically simple. Our customers value not only our technical expertise but especially the clarity of the process and our commitment to sustainable standards.

We thank our Swiss partner for the trust and willingness to take a different path with us — for a responsible approach to resources and a functioning circular economy in industry.

https://youtu.be/h_0TneOwdfo

Further information such as price and delivery time for:

Yaskawa Servopack DR2-04ACP

More details about our Yaskawa repair expertise can be found here: Yaskawa DR2 repairs by Industrypart

Similar models we regularly repair:

DR2-04AC

DR2-04ADY135

📞 Please feel free to contact us if you have any questions regarding your Omron drive technology. Our experienced team is always available to assist you.

Device Data (Technical Specifications of DR2-04ACP)

| Parameter | Value |

|---|

| Model | DR2-04ACP |

| Series | Σ-Series DR2 Servopack |

| Input Voltage | 200–230 V AC (Single-phase) |

| Frequency | 50/60 Hz |

| Input Current | 5.1 A |

| Output Voltage | 0–230 V AC |

| Output Current | 2.8 A (3-phase) |

| Power Output | 0.4 kW (0.54 HP) |

| Compatible Motors | SGMP Servomotor (as per nameplate info) |

| Encoder Type | Incremental/Absolute (Type C) |

| Cooling | Natural convection (ventilated housing) |

| Protection Class | IP2X |

| Manufacturer | Yaskawa Electric, Japan |

| Date of Manufacture | 06/2010 (as stamped on the housing) |

Operating Environment & Compatibility

The DR2-04ACP is typically used in:

- CNC machines, pick-and-place units, semiconductor processing equipment

- Pairing with SGMP-series servomotors (small, precision motors)

- Installation environment:

- Ambient temperature: 0–55 °C

- Relative humidity: 20–80 % (non-condensing)

- Vibration: max. 0.5 G

- No exposure to water or corrosive gases

- Vertical mounting in electrical cabinets recommended, with ≥50 mm space above/below for ventilation

Function Description

The Yaskawa DR2-04ACP Servopack is an amplifier unit from the Σ-Series, enabling precise control of AC servomotors. It supports:

- Position control (via pulse train input)

- Speed control (via analog voltage input)

- Torque control (optional mode)

- Communication possible via digital operator (e.g., JUSP-OP02A)

- Compatible with both incremental and absolute encoders (depending on settings and wiring)

- Internal regenerative braking supported; external resistor optional

Alarm Messages & Troubleshooting

| Error Code | Detection | Remarks / Suggested Action |

|---|

| A.00 | Absolute Encoder Data Error | Only occurs with absolute encoder (Type SGDB, DR2) |

| A.10 | Overcurrent | Check motor/load wiring; possible short or overload |

| A.20 | Blown Fuse | Replace internal fuse |

| A.30 | Regeneration Error | Check regenerative unit/wiring (if used) |

| A.40 | Overvoltage | Check AC input voltage and brake resistor |

| A.50 | Main Circuit Voltage Error | Unstable supply — check power input |

| A.60 | Feedback Overspeed | Motor exceeded max speed — check encoder feedback |

| A.70 | Overload | Temporary overload — inspect motor/load |

| A.71 | Continuous Overload | Sustained overload — possible undersized motor |

| A.81–A.85 | Encoder & battery related errors | Only relevant to 12-bit absolute encoders — check battery & cables |