29.10.2025 by Viktor Siebert

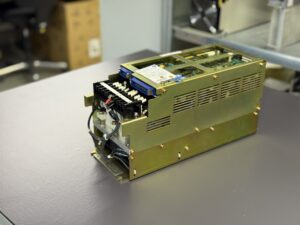

Repair of a Yaskawa CACR-SR20BF1AM Re-Engineered Servopack

Overview

The model CACR-SR20BF1AM belongs to Yaskawa’s Re-engineered Servopack family, developed as a direct replacement for earlier CACR-SR series drives. Although these units maintain identical mechanical structure and connector layouts, they internally use modern Sigma-III technology.

Through a complex configuration of hardware jumpers, internal bridges, and software parameters, this generation can emulate a wide range of older Yaskawa drives and motor types, from the M-Series to the S-Series.

The Servopack supports both analog and serial encoders and can handle multiple resolutions between 1000 and 8192 pulses per revolution, making it a highly versatile replacement platform. However, this flexibility also makes configuration challenging, requiring in-depth technical understanding, original programming tools, and proper alignment between motor and control system.

Fault Description and Diagnosis

The customer received one of our preconfigured exchange units to replace a defective original Servopack. We currently maintain about 50 of these re-engineered CACR-SR units in stock, each tested and partially parameterized for standard replacement use.

Shortly after installation, the customer reported Alarm A.41 appearing immediately at power-up. According to Yaskawa documentation, this indicates an invalid or contradictory PG Dividing Pulse Output (Pn212) parameter.

Upon review, it became evident that the required parameter adaptation to the specific motor and control system had not been performed. With re-engineered Servopacks, such adaptation is mandatory, as each configuration requires precise alignment of the dividing ratio, encoder type, inertia ratio, gain settings, and regenerative parameters.

Since the customer was unable to perform this alignment, the original defective Servopack was sent to us for repair and analysis.

Repair and Parameterization Process

Upon arrival, both units, the replacement Servopack and the defective original – were examined in parallel. The power stage was electrically stable, but several control circuits showed logic faults and drift in signal conditioning stages.

The replacement device was then reparameterized on our dedicated Yaskawa test bench. Using the JUSP-OP05A digital operator and internal software tools, all key parameters were read out, compared, and matched precisely to the original configuration.

The procedure included:

- Parameter verification (Pn000–Pn520) and cross-comparison with backup data from the original unit.

- Encoder configuration (DSW1/DSW5) according to motor type and feedback system.

- Speed loop and current gain tuning using potentiometers ZERO, FINE, and CUR.

- Verification of all internal jumpers (CN4–CN26) following Yaskawa’s technical tables.

- PG signal calibration via oscilloscope to ensure phase synchronization (A/B/C signals).

- Long-term load testing for four hours with repeated on/off cycles to confirm operational stability.

After all calibrations, both units operated identically. The customer requested to keep both units one installed and one stored as a spare so the repaired Servopack was supplied together with a fully parameterized backup device.

Testing and Quality Assurance

Final testing was performed with a reference motor USAMED-20A and an incremental encoder of 2048 p/r. A simulated load equal to 80% nominal torque was applied. Temperature, current, and rotational feedback were continuously monitored.

All measurements remained within tolerance:

- Current deviation: < 2%

- Speed regulation: < 0.01%

- Heatsink temperature rise: < 20 °C

Additional communication stability checks were made using the JUSP-OP05A operator to ensure no CRC or communication loss occurred. Following the successful test sequence, both drives were sealed, labeled, and stored with a verified parameter file for future use.

Conclusion

The restoration of the Yaskawa CACR-SR20BF1AM illustrates the complexity and technical depth of re-engineered Servopack systems. While they are designed as direct mechanical replacements, they require precise parameter mapping and electrical calibration to achieve full compatibility and reliability.

Thanks to a structured diagnostic process and the experience of our technicians, both units were fully restored and synchronized. This case demonstrates that professional repair involves far more than part replacement: it requires an understanding of drive behavior, encoder technology, and closed-loop calibration.

Only through such expertise can the original performance, stability, and longevity of Yaskawa’s servo systems be maintained.

To mentioned Yaskawa Drive: Yaskawa CACR-SR20BF1AM Re-Engineered Servopack

More details about our Yaskawa repair services can be found here:

Yaskawa drive Repair by Industrypart

📞 Feel free to contact us with any questions about your Yaskawa drive technology.

Our expert team is happy to help!

Technical Specifications:

| Specification | Description |

|---|

| Model | CACR-SR20BF1AM |

| Max. Motor Capacity | 2.0 kW |

| Input Voltage | 3-phase 200–230 VAC ±10%, 50/60 Hz |

| Continuous Output Current | 19 A |

| Maximum Output Current | 42 A |

| Control Method | IGBT-PWM, sine-wave drive |

| Feedback | Incremental or absolute encoder (up to 8192 p/r) |

| Ambient Temperature | 0–55 °C |

| Protection Functions | Overcurrent, over/undervoltage, overheating, CPU error, encoder error |

| Weight | approx. 10 kg |

| Mounting | Base-mounted, forced ventilation |

Alarm Messages and Troubleshooting

| Code | Alarm name | Meaning, cause | Stop method | Reset |

|---|

| A.041 | Dividing Pulse Output Setting Error | PG dividing pulse Pn212 invalid or inconsistent | DB stop | Not available |

| A.400 | Overvoltage | DC bus voltage too high | DB stop | Available |

| A.410 | Undervoltage | DC bus voltage too low | Zero-speed stop | Available |

| A.300 | Regeneration Error Detected | Fault in regenerative circuit or resistor | DB stop | Available |

| A.320 | Regenerative Overload | Regenerative energy exceeds resistor capacity | Zero-speed stop | Available |

| A.510 | Overspeed | Servo speed excessively high | DB stop | Available |

| A.710 | Overload: High Load | Short high overload above rated torque | Zero-speed stop | Available |

| A.720 | Overload: Low Load | Continuous overload above rated torque | DB stop | Available |

| A.C10 | Servo Overrun Detected | Axis ran out of control range | DB stop | Available |

| A.d00 | Position Error Pulse Overflow | Position error exceeded Pn520 | DB stop | Available |

| A.F10 | Power Line Open Phase | One phase of main power missing | Zero-speed stop | Available |