08.10.2025 by Viktor Siebert

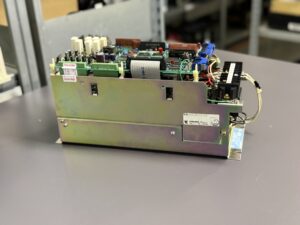

Repair of a Yaskawa CACR-SR15BB1BF-B with burnt control board and faulty power supply

A customer sent in a non-functional CACR-SR15BB1BF-B. Visual inspection revealed burnt components on the control board.

The power section was tested first, no anomalies were found. We replaced the control PCB to verify if the power supply was still operational.

However, the unit still failed to start the internal PSU was damaged, likely caused by the initial short on the control board.

After complete overhauling of both modules, including replacement of electrolytics and optocouplers, the drive powered up but displayed Error 01 Overcurrent.

Using an oscilloscope and current probe, our technicians traced the fault to a damaged feedback path in the power supply section, which falsely triggered overcurrent detection.

After rebuilding the feedback circuit and calibrating the signal chain, the fault was cleared.

The Servopack was then tested with a USAFED-13C motor under full load for 24 hours.

All functions — acceleration, deceleration, torque control operated flawlessly, and the temperature remained within nominal range.

Because this model is discontinued, repair is the only sustainable solution.

While used drives on the secondary market are often degraded, our restored units are fully calibrated, parameterized, and tested under load, ensuring performance and reliability.

Preventive Maintenance Tips

- Regular heat sink cleaning (at least once per year)

- Inspection of connectors and insulation

- Replacement of electrolytic capacitors every 5–7 years

- Check regeneration resistor value

- Verify grounding and phase order

- Keep ambient temperature below +45 °C

Conclusion

A professional overhaul of the CACR-SR15BB1BF-B restores full performance and machine safety.

Scheduled maintenance avoids unplanned downtime and extends the life of legacy CNC systems where spare parts are no longer available.

To mentioned Yaskawa Drive: Yaskawa CACR-SR15BB1BF-B Servopack

More details about our Yaskawa repair services can be found here:

Yaskawa drive Repair by Industrypart

📞 Feel free to contact us with any questions about your Yaskawa drive technology.

Our expert team is happy to help!

Technical Specifications:

| Parameter | Description |

|---|

| Model | Yaskawa CACR-SR15BB1BF-B |

| Type | AC Servopack (Speed Control) |

| Series | M·F·S·D Series |

| Rated Power | 1.5 kW |

| Input Voltage (Main) | 3 × 200–230 V AC ±15%, 50/60 Hz |

| Control Voltage | 1 × 200–230 V AC ±10% |

| Rated Output Current | 11.7 A |

| Max Output Current | 28 A |

| Control Method | Transistorized PWM Control |

| Speed Control Range | 1 : 3000 |

| Feedback System | Optical Encoder (A = 6000, B = 5000, D = 4000 pulse/rev) |

| Cooling | Base cooled, natural convection |

| Ambient Temperature | 0 – +55 °C |

| Humidity | ≤ 90% RH (non-condensing) |

| Vibration | 0.5 G |

| Mounting Method | Wall mounting, vertical, heat sink down |

| Weight | approx. 5.5 kg |

| Manufacturer | Yaskawa Electric Corporation |

| Production Year | ca. 1996 |

| Manual Reference | Yaskawa TSE-S800-2.1J, p. 17 ff. |

Application Environment & Compatible Devices

The CACR-SR15BB1BF-B Servopack belongs to Yaskawa’s D-Series of AC Servo Drives and is primarily used for speed control applications in CNC machines, robots, and automation systems.

Typical environments include machine tools, machining centers, and robotic axes requiring precise speed regulation.

Compatible Servo Motors:

- USADED-15E (1.5 kW, 2000 rpm)

- USAFED-13C (1.3 kW, 1500 rpm)

- USAMED-12B (1.2 kW, 1000 rpm)

These units are fully compatible with Yaskawa incremental encoder systems and can be directly controlled by CNC systems such as FANUC, Mitsubishi, or Okuma.

Functional Description

The CACR-SR15BB1BF-B is a transistorized PWM amplifier operating within a closed-loop speed control system.

Its integrated microprocessor processes encoder feedback, regulates voltage and current, and ensures full protection through internal monitoring against overcurrent, overtemperature, and overvoltage.

Key Features:

- Speed control via ±6 V analog input

- External current limit via P-CL / N-CL

- Servo ready monitoring (S-RDY)

- Dynamic braking in case of alarm

- Optical encoder feedback with selectable frequency division (1/1 – 1/64)

The control circuitry uses hybrid ICs for compact size, reliability, and efficient signal processing.

Alarms & Troubleshooting

| Code | Error Description | Cause | Solution |

|---|

| 1 | Overcurrent | Short circuit in power section or motor failure | Check transistor module, test motor insulation |

| 2 | Circuit breaker trip | Overload or missing phase | Inspect input voltage and fuses |

| 3 | Regeneration fault | Regeneration resistor open or defective | Check resistor, connection and relay |

| 4 | Overvoltage | Excessive mains voltage or brake fault | Check mains supply, measure DC bus |

| 5 | Overspeed | Encoder signal error or polarity mismatch | Check encoder connection and polarity |

| 6 | Undervoltage | DC bus < 150 V | Check input supply |

| 7 | Overload | Continuous excessive current | Inspect mechanical load |

| 8 | Heat sink overheat | Fan failure or dust contamination | Clean and check cooling |

| 9 | A/D Error | Failure in control logic | Replace control board |

| A | Open phase | Missing phase in supply | Verify three-phase connection |

| b | CPU Error | Internal memory error | Perform reset or replace PCB |

Components

| Module | Designation / Code | Function | Service Notes |

|---|

| Power Board | Main Power PCB | Converts mains via PWM transistors to controlled power output | Check for transistor shorts |

| Control Board | Logic PCB | Signal processing, PID control, protection circuits | Visual check for burns or failed optocouplers |

| Gate Driver | Driver Section | Controls transistor gate pulses | Verify signal integrity |

| Heat Sink Assembly | Cooling System | Heat dissipation | Clean and test thermal performance |

| Regenerative Resistor | JUSP-RA03 | Dissipates braking energy | Check for resistance value and continuity |

| Cooling Fan | optional | External cooling | Replace when noisy or unstable |