08.01.2026 by Viktor Siebert

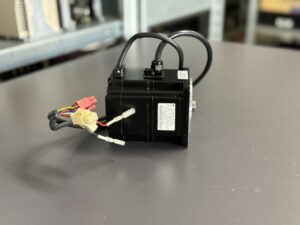

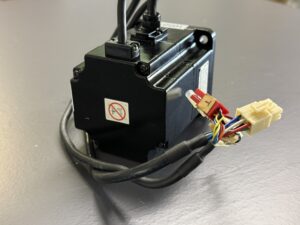

Repair of a Yaskawa AC Servo Motor SGMPH-02A1A-YR31 with Brake Failure

Initial Situation and Reported Fault.

The Yaskawa AC Servo Motor SGMPH-02A1A-YR31 was sent in with the fault description that the integrated holding brake opens correctly when energized, but no longer closes reliably during operation. This behavior occurred reproducibly and resulted in the axis no longer being held securely at standstill. Especially in vertical axes or load bearing applications, such behavior represents a significant functional and safety risk.

The motor is equipped with a high resolution encoder of type UTSAH-B16DC-E as well as an integrated spring applied holding brake manufactured by Ogura Clutch. The motor was tested on a Yaskawa SGDH-02AE Servopack, allowing a realistic functional test under industrial conditions.

Initial Inspection and Disassembly

After incoming inspection, an external visual check was carried out first. The motor housing showed clear signs of long term industrial use. No obvious mechanical damage to the shaft or flange was visible, however an uneven resistance could already be felt when turning the shaft manually.

In the next step, the motor was completely disassembled. At this point, the actual root cause of the reported fault became immediately apparent. The friction lining of the integrated holding brake was completely worn down. Due to the advanced wear, fine brake dust had spread throughout the entire interior of the motor. This abrasive material was not limited to the brake area but was also found on the rotor, stator and in close proximity to the encoder.

Internal Damage Assessment

The extensive brake abrasion posed a serious risk to the entire motor assembly. Such particles can become electrically conductive, trap heat and cause long term insulation issues. Although the encoder was still functioning correctly at the time of initial measurement, the heavy contamination made a future failure highly likely.

The bearings also showed age related wear marks. Combined with the contamination and general condition, it was clear that a partial repair would not be sufficient in this case. The objective was not only to restore short term functionality, but to ensure long term operational reliability.

Repair and Overhaul Measures

The motor was completely cleaned and all deposits were removed. The housing underwent a full paint removal process in order to eliminate hidden contamination and early corrosion. This was followed by a professional repainting process, which serves not only cosmetic purposes but also protects the housing surface.

All ball bearings were replaced, as well as all sealing elements. Especially for motors of this generation, the condition of the seals is critical, as even minor leaks over many years can lead to progressive internal damage.

The defective brake was completely replaced. A new, equivalent holding brake was installed, precisely matched to the mechanical and electrical requirements of the motor. The encoder was overhauled preventively, cleaned, readjusted and fully tested again to ensure accurate position feedback.

Reassembly and Functional Testing

After reassembly, the motor was tested on a Yaskawa SGDH-02AE Servopack. Both dynamic motion sequences and extended standstill phases were simulated. The brake now opened and closed cleanly and reproducibly. The behavior remained stable even after repeated cycles.

Torque output, current consumption and encoder signals were monitored during testing. All measured values remained within expected tolerances. The motor operated smoothly without abnormal noise or vibration. The repair was therefore completed successfully.

Importance of Preventive Maintenance

This repair case clearly demonstrates the importance of preventive maintenance for servo motors equipped with integrated brakes. Brake lining wear develops gradually and often remains unnoticed during normal operation. Only when the brake no longer closes reliably does the problem become visible. At that stage, abrasive particles are often already distributed throughout the motor interior.

Timely overhaul can prevent such secondary damage, significantly extend the service life of the motor and avoid unplanned machine downtime.

Information about the mentioned Servomotor and other components:

Yaskawa AC Servo Motors SGMPH-02A1A-YR31

More information about our Yaskawa repairs can be found here.

📞 Feel free to contact us if you have any questions regarding your Yaskawa drive tech

Technical SectionTechnical Specifications

| Parameter | Value |

|---|

| Manufacturer | Yaskawa Electric Corporation |

| Motor Type | AC Servo Motor |

| Model | SGMPH-02A1A-YR31 |

| Rated Voltage | 200 V |

| Rated Power | approx. 200 W |

| Rated Current | 2.0 A |

| Rated Torque | approx. 0.637 Nm |

| Rated Speed | 3000 rpm |

| Insulation Class | B |

| Year of Manufacture | 1999 |

| Encoder | UTSAH-B16DC-E |

| Brake | Ogura Clutch MCNB10Y-03 |

| Test Drive | Yaskawa SGDH-02AE |

Typical Alarms and Faults During Operation

| Alarm | Description | Possible Cause | Corrective Action |

|---|

| Brake Error | Brake does not open or close correctly | Wear or contamination | Inspect and replace brake |

| Encoder Alarm | Position feedback faulty | Contamination or aging | Clean or overhaul encoder |

| Overload | Mechanical overload | Dragging bearings or brake | Check mechanical components |

| Overheat | Excessive temperature | Abrasion or poor heat dissipation | Clean and service |

| Servo Alarm | Position deviation | Mechanical resistance | Inspect mechanics and brake |

Main Components

| Assembly | Designation | Function |

|---|

| Stator | Winding assembly | Magnetic field generation |

| Rotor | Permanent magnet rotor | Rotational movement |

| Encoder | UTSAH-B16DC-E | Position feedback |

| Holding Brake | MCNB10Y-03 | Axis holding at standstill |

| Bearings | Precision ball bearings | Low friction rotation |

| Seals | Shaft seals | Protection against dust and moisture |

Typical Applications

| Application | Description |

|---|

| CNC machine tools | Axis drives with holding function |

| Automation systems | Positioning tasks |

| Vertical axes | Secure holding at standstill |

| Special machinery | Precise motion control |