16.12.2025 by Viktor Siebert

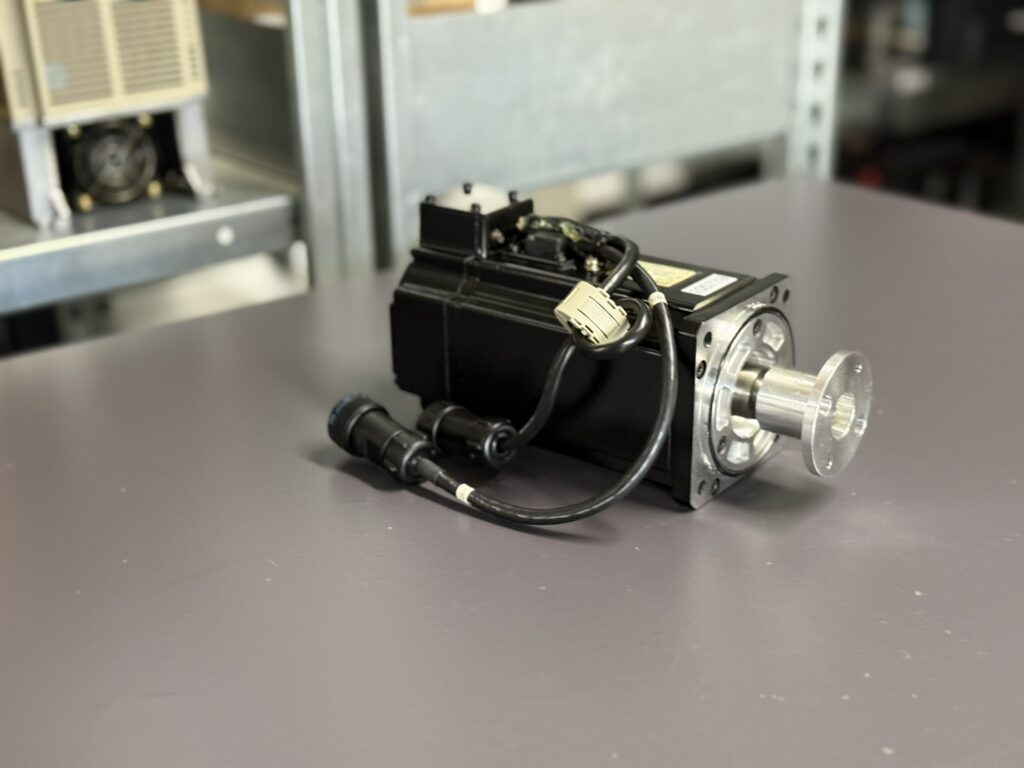

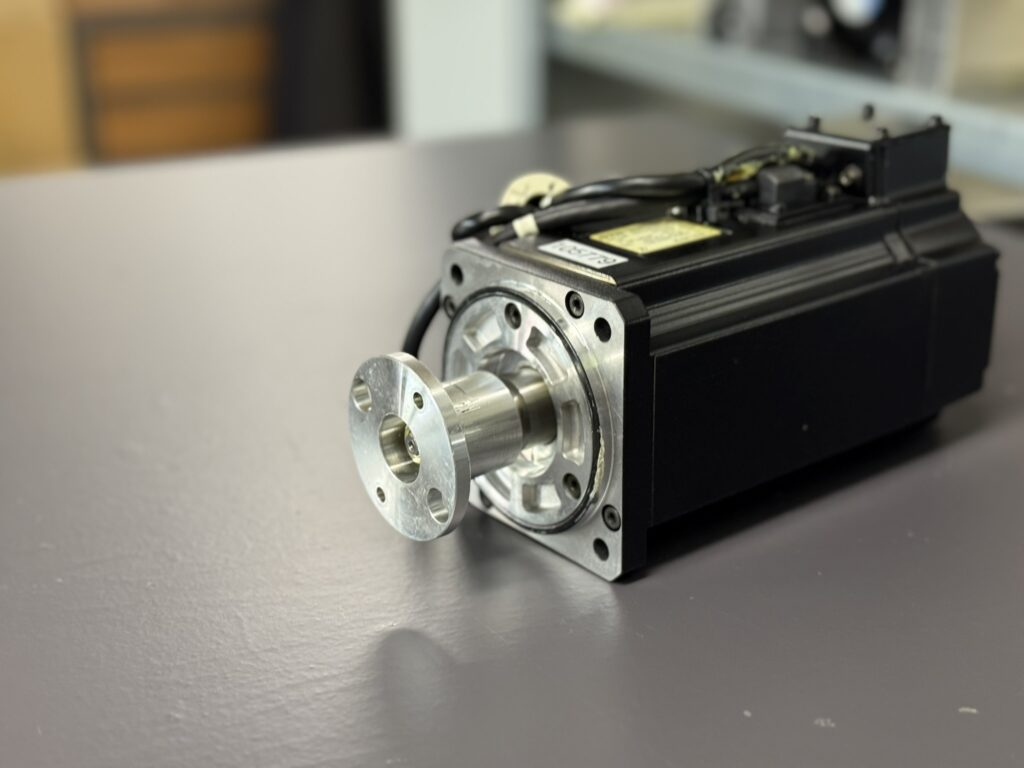

Repair of a Yaskawa AC Servo Motor SGMGH-05K5A-SE11 with intermittent encoder fault

The Yaskawa AC servo motor SGMGH-05K5A-SE11 was delivered to us together with the associated servo drive SGDK-050505AEA-V for analysis. The customer reported an intermittent encoder fault but was not certain whether the root cause was located in the motor or in the servo drive. Several identical axes were installed in the machine, which led the internal maintenance team to swap servo drives between axes. This approach resulted in additional faults because the drives were machine-specific parameterized and each swap required re-parameterization.

To clearly identify the fault, we tested the motor on a Star CNC machine under realistic operating conditions. This allowed us to reliably reproduce the fault. After a short operating time it became evident that the servo drive was working correctly, while the encoder signal showed intermittent dropouts.

After opening the motor, the damage pattern became clear. The encoder was completely contaminated with oil. The penetrating emulsion had accumulated inside the encoder housing over time and damaged the encoder disc. The disc was mechanically and optically damaged to such an extent that refurbishment was no longer possible. The root cause was clearly a aged or damaged seal that allowed oil to enter the motor housing.

As part of the repair, the complete encoder was professionally removed and replaced with a new original UTSAH-B17BE encoder. In addition, the motor interior was thoroughly cleaned, the winding was visually inspected and insulation-tested, and all mechanical components were changed. After reassembly, the motor was operated again on the test stand and tested under load over an extended period. The encoder signal remained stable, the control loop operated cleanly, and no further alarms occurred.

Preventive measures for the customer

Regular visual inspection of motor seals

Inspection for oil or emulsion near encoder and connectors

Insulation measurement at defined maintenance intervals

Preventive replacement of seals on older motors

No axis or drive swapping without prior parameter backup

Conclusion

This repair case clearly demonstrates that intermittent encoder faults are very often caused by gradual contamination. Without reproducible testing under real operating conditions, the root cause would have been difficult to identify. Professional diagnostics combined with a clean repair process and preventive measures restore long-term operational reliability and help avoid unnecessary machine downtime.

Information about the mentioned Servopack and Servomotor:

More information about our Yaskawa repairs can be found here.

📞 Feel free to contact us if you have any questions regarding your Yaskawa drive technology. Our experienced team is always ready to assist you.

Technical Specifications

| Parameter | Value |

|---|

| Manufacturer | Yaskawa Electric |

| Motor type | AC servo motor |

| Model | SGMGH-05K5A-SE11 |

| Rated power | 450 W |

| Rated torque | 2.86 Nm |

| Rated speed | 1500 rpm |

| Supply voltage | 200 V AC |

| Rated current | 4.4 A |

| Insulation class | F |

| Duty type | Continuous duty |

| Encoder | Yaskawa UTSAH-B17BE |

| Cooling | Convection cooled |

| Mounting type | Flange motor |

| Production date | 03/2009 |

| Origin | Made in Japan |

Operating environment and compatible devices

The Yaskawa SGMGH-05K5A-SE11 is typically used in CNC machines, machine tools and automated production systems. It is usually operated together with Sigma-II and Sigma-III servo drives. In this case, the motor was combined with a Yaskawa Servopack SGDK-050505AEA-V. This combination is commonly found in machines with several identical axes, where exact axis-specific parameterization is required.

Functional description

The servo motor of the SGMGH series is designed for precise speed, position and torque control. Feedback is provided by a high-resolution encoder that continuously supplies position and speed information to the servo drive. The servo drive uses this data to control current and torque behavior and to monitor safety-relevant operating conditions. Even minor disturbances in the encoder signal can lead to unstable control behavior or sporadic shutdowns.

Alarm messages and troubleshooting

| Code | Fault description | Possible cause | Remedy |

|---|

| 0x10 | Overcurrent | Moisture in the motor, low winding insulation | Inspect and clean motor and encoder |

| 0x11 | Ground fault | Ingress of liquid, damaged sealing | Inspect and replace seals |

| 0x51 | Overspeed | Faulty encoder feedback | Inspect and replace encoder |

| 0x63 | Pulse count error | Signal disturbance due to moisture | Replace encoder |

| 0x71 | Momentary overload | Increased motor current | Perform insulation measurement |

| 0x74 | Starting current overload | Residual moisture in stator | Drying and inspection |

| 0x79 | Motor overtemperature | Leakage current caused by emulsion | Cleaning and preventive maintenance |

Components

| Assembly | Designation | Function | Notes |

|---|

| Encoder | UTSAH-B17BE | Position feedback | Highly sensitive to oil contamination |

| Stator | Winding assembly | Torque generation | Insulation condition is critical |

| Rotor | Permanent magnet | Mechanical output | Visual inspection recommended |

| Bearings | Precision bearings | Smooth rotation | Preventive replacement recommended |

| Seals | Shaft seal | Protection against media ingress | Regular inspection required |