15.01.2026 by Viktor Siebert

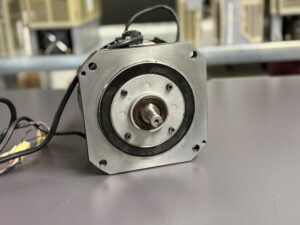

Repair of a Yaskawa AC Servo Motor SGMDH-06A2A-YR13 from a Yaskawa Robot

Initial Situation and Fault Condition at Arrival.

The Yaskawa AC Servo Motor SGMDH-06A2A-YR13 was sent to us by an automotive company. The motor was installed in a Yaskawa industrial robot and was responsible for an axis function requiring high dynamics and repeat accuracy. According to the customer, functional problems developed gradually until the robot was ultimately no longer operational.

After arrival at our workshop, an initial inspection was carried out on our Yaskawa-compatible motor test bench. It was immediately apparent during power-up that the motor would not start. Communication between the drive and the motor could not be established correctly. The connected servo amplifier consistently displayed alarm AL.81. This alarm indicates a problem in the feedback system, specifically an incompatibility or defect related to the encoder or its signal connection.

In parallel, the mechanical inspection revealed that the integrated holding brake no longer provided any effective holding torque. In the de-energized state, the motor shaft could be rotated freely. Neither a defined release nor a reliable engagement of the brake was possible. For a robot motor, this represents a significant safety risk, as axes may drop or continue moving uncontrollably.

Diagnosis of Encoder and Brake

The motor is equipped with an absolute encoder type UTSAE-B17BBF. This encoder could not be initialized or reset in the test setup. Reset attempts failed repeatedly, directly triggering alarm AL.81. Based on experience, such behavior typically indicates internal electronic damage within the encoder or age-related signal issues, for example due to thermal stress, vibration, or moisture ingress over time.

In addition, the motor is fitted with an integrated spring-applied brake manufactured by Ogura. According to the customer documentation, the brake operates at DC 90 V, but the holding torque specified on the motor was clearly no longer present. The exact brake model could not be identified externally, as the detailed designation is only marked internally. In such cases, complete disassembly of the motor is necessary to identify and properly assess the installed brake.

Disassembly and Findings

After complete disassembly of the motor, a clear damage pattern emerged. The encoder showed internal aging effects. Although the electronics appeared visually intact, the absolute position feedback was no longer stable or reproducible. Repair of the encoder was no longer economically viable in this condition.

The brake showed significant wear. The friction lining was worn, the spring force was insufficient, and the magnetic unit no longer operated reliably. As a result, no defined holding torque could be generated. For robotic applications, this meant that the brake had failed in a safety-critical manner.

In addition, age-related wear was found on seals and bearings. The grease in the ball bearings had hardened, and the seals had lost elasticity. Such conditions inevitably lead to increased friction, higher operating temperatures, and secondary damage if left unaddressed.

Repair Measures Performed

As part of the overhaul, the motor was completely refurbished. The absolute encoder UTSAE-B17BBF was replaced with a suitable new unit and subsequently electrically tested. The brake was completely replaced, including the magnetic assembly and friction components, restoring the original holding torque reliably.

Furthermore, all ball bearings and seals were replaced as a preventive measure. The motor housing was stripped of old paint, cleaned, and repainted to restore corrosion protection and visual quality. After mechanical reassembly, comprehensive electrical testing and an extended test run on the test bench were carried out.

Following these measures, the motor could be initialized without issues, the encoder reset successfully, and alarm AL.81 no longer occurred. The brake operated reproducibly and held the axis securely in the stationary state.

Final Test and Release

The refurbished motor was tested under realistic operating conditions. Speed, current consumption, temperature behavior, and brake switching performance were all within specified limits. Only after successful completion of the final inspection was the motor approved for return shipment.

This case clearly demonstrates how important a holistic evaluation of encoder, brake, and mechanical components is for robot motors. Individual defects rarely occur in isolation but are usually part of an overall age-related condition.

Information about the mentioned Servopack and Servomotor:

More information about our Yaskawa repairs can be found here.

📞 Feel free to contact us if you have any questions regarding your Yaskawa drive technology. Our experienced team is always ready to assist you.

Technical Specifications

| Parameter | Value |

|---|

| Manufacturer | Yaskawa Electric |

| Model | SGMDH-06A2A-YR13 |

| Motor type | AC servo motor |

| Rated power | 550 W |

| Rated voltage | 200 V |

| Rated current | approx. 4.0 A |

| Rated torque | 2.63 Nm |

| Rated speed | 2000 rpm |

| Encoder | Absolute encoder UTSAE-B17BBF |

| Brake | Ogura RNB 0.25K-06 DC-90V |

| Insulation class | F |

| Application type | Robotics, automation |

Typical Operating Environment and Applications

| Area | Description |

|---|

| Industry | Automotive production |

| Machine | Yaskawa industrial robot |

| Function | Axis drive with holding function |

| Operating mode | Continuous operation with high dynamics |

| Environment | Control cabinets, robot bases, production lines |

Relevant Alarm Messages (Excerpt CACR-IR Series)

| Alarm code | Description | Cause | Action |

|---|

| AL.81 | Sub side detector cable error | Encoder or cable incompatible or defective | Check or replace encoder |

| AL.10 | Encoder communication error | No stable feedback | Check encoder or cable |

| AL.11 | Encoder error | Position data faulty | Replace encoder |

| AL.46 | Motor overheat | Overload or cooling issue | Check mechanics and load |

Main Assemblies

| Assembly | Designation | Function |

|---|

| Encoder | UTSAE-B17BBF | Absolute position feedback |

| Brake | Ogura spring-applied brake | Holding function at standstill |

| Bearings | Ball bearing set | Mechanical guidance |

| Seals | Shaft seals | Protection against dirt and moisture |

| Stator and rotor | SGMDH series | Torque generation |

Conclusion

The repair of the Yaskawa SGMDH-06A2A-YR13 clearly shows that encoder and brake failures in robot motors often occur together. A partial repair would not have been sufficient in this case. Through a complete overhaul including encoder, brake, bearings, and seals, the motor was restored to a technically and safety-wise near-new condition. Preventive refurbishment is clearly more economical in such applications than unplanned downtime or safety risks.