28.11.2025 by Viktor Siebert

Safety and Performance Testing for Yaskawa Servodrives

Whether during repair or preventive maintenance of Yaskawa servo drives and motors, long-term reliability and stable machine availability can only be achieved through consistent and systematic testing. Structured validation processes help prevent unplanned downtime in complex production environments.

Reliable manufacturing depends on precise control behavior and robust drive technology. For this reason, all repaired Yaskawa modules at industrypart undergo comprehensive electrical, thermal, and dynamic testing. Our purpose-built test benches simulate real load profiles and operating conditions, ensuring repeatable performance, predictable service life, and a safe, sustainable maintenance strategy.

Our testing processes for Yaskawa drive technology

- Fault analysis and root cause identification

- Mechanical visual inspection and professional cleaning

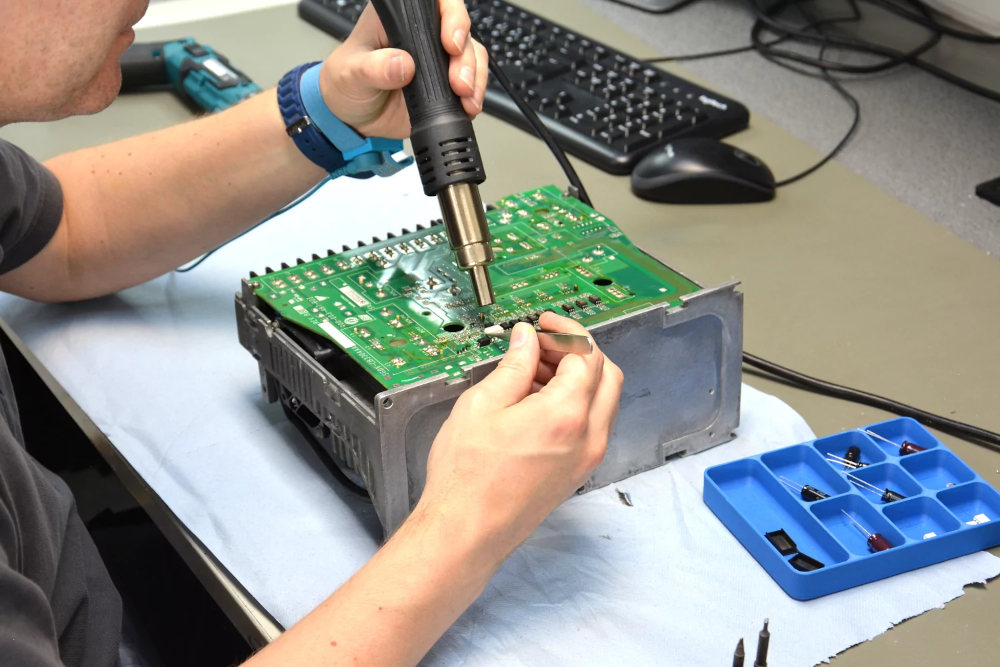

- Replacement of defective power modules, sensors, and electronic components

- Electrical, thermal, and dynamic functional testing

- Simulation of real load and torque conditions

- Testing of feedback systems such as encoders and resolvers

- Verification of control, communication, and feedback functions

- Monitoring of current consumption, voltage stability, and thermal behavior

- Testing of typical alarm codes and shutdown conditions

- Complete documentation of all measurement points and structured checklists

- Long-term endurance testing under variable load

- Parameter verification and drive tuning after repair

These comprehensive test procedures ensure that refurbished Yaskawa Servodrives meet high safety and performance standards and are ready for reliable operation immediately after reinstallation.

In addition, we also offer further test procedures for different manufacturers.