10.07.2025 by Viktor Siebert

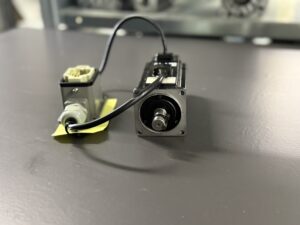

Tool Changer Malfunction – 24h Repair of an Omron R7M-A20030-BS1 Servo Motor

A service company specializing in machine tools contacted us with an urgent issue. They had refurbished a Gildemeister machine and sold it to a customer. A few months later, the buyer reported problems: the tool changer was unreliable and required frequent recalibration.

Initially, the SmartStep servo drive R7D-AP02H was suspected. It was replaced by a brand-new unit without success. The error persisted.

While searching for solutions online, the machine dealer found our company. We were immediately familiar with the issue. In most cases, the fault lies in the encoder the Yaskawa TRD-FY2000 – which is known to fail on this specific motor type. This encoder was developed by Yaskawa specifically for Omron, and although similar motors exist, none have a compatible encoder.

We’ve been repairing these motors for years and are fully aware of the specifics. We also stock new replacement encoders that are specially adapted for this model. This enables us to offer a reliable, long-term repair solution. Standard turnaround time is typically 4 to 7 working days.

However, due to the urgency of the case, the customer had the motor delivered to us by express courier. All spare parts were in stock, and we completed the overhaul within 24 hours. The repaired motor was sent back via express service, and the machine has been running smoothly ever since no further calibration needed.

Technical Repair Procedure for Omron R7M-A20030-BS1

Incoming Inspection:

- Visual inspection for mechanical damage

- Verification of model and serial number

- Insulation resistance test

Disassembly and Diagnostics:

- Full motor disassembly and opening of brake assembly

- Bearing condition check for wear and axial play

- Encoder diagnosis using oscilloscope and signal testing

- Brake coil resistance and holding torque measurement

Repair Measures:

- Replacement of the encoder with original TRD-FY2000 (customized for Omron)

- Cleaning and resealing of housing parts

- Replacement of bearings with premium industrial-grade brands (e.g. NSK/FAG)

- Adjustment and testing of braking performance

- Reassembly with precise torque settings

Functional Testing:

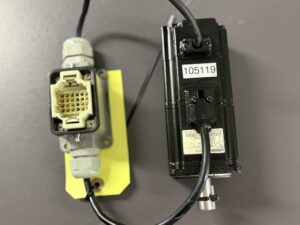

- Connection to original Omron SmartStep Drive R7D-AP02H

- Complete test run in our dynamic load test bench

- Load testing across full speed range

- Repeated positioning accuracy tests

- Brake holding test under power-off conditions

Final Steps:

- Full documentation of test results

- Labelling with test date and internal tracking number

- Packaging in shock-protected shipping container

- Return shipment via express courier

Information about the mentioned Servopack and Servomotor:

More information about our Omron repairs can be found here.

📞 Feel free to contact us if you have any questions regarding your Omron drive technology. Our experienced team is always ready to assist you.

Technical Specifications – Omron R7M-A20030-BS1 Servo Motor

| Parameter | Specification |

|---|

| Model | R7M-A20030-BS1 |

| Type | Cylindrical AC Servo Motor with Brake |

| Rated Output Power | 200 W |

| Rated Torque | 0.637 N·m |

| Rated Speed | 3,000 rpm |

| Rated Current | 2.0 A (rms) |

| Power Supply Voltage | 200 VAC (via SmartStep Driver R7D-AP02H) |

| Encoder Type | Incremental encoder (Yaskawa TRD-FY2000 or equivalent) |

| Encoder Resolution | 2,000 pulses/revolution (A/B phases) + 1 pulse/rev (Z phase) |

| Brake Type | 24 VDC holding brake |

| Brake Models Used | KYOWA SEIKO KS-50B-086 or OGURA CLUTCH MCNB-15Y-06 |

| Brake Power Consumption | 7 W |

| Brake Holding Torque | ≥ 1.47 N·m |

| Insulation Class | Class B |

| Enclosure | Totally enclosed, IP55 (excluding shaft end) |

| Cooling Method | Self-cooling (natural air convection) |

| Mounting | Flange-mounted |

| Operating Temp. Range | 0 to 40 °C |

| Operating Humidity | 20–80 % RH (non-condensing) |

| Storage Temp. Range | –20 to 60 °C |

| Weight (incl. brake) | Approx. 1.6 kg |

Alarm Table – Omron R7D-AP02H (SmartStep A)

| Code | Error Type | Cause of Error |

|---|

| A.04 | Parameter Setting Error | The connected servomotor does not match the configured servo driver |

| A.10 | Overcurrent | Overcurrent detected or temperature rise in the radiation shield |

| A.30 | Regeneration Error | Regeneration circuit damaged due to excessive regenerative energy |

| A.32 | Regeneration Overload | Regenerative energy exceeded the capacity of the regeneration resistor |

| A.40 | Over-/Undervoltage | Main circuit DC voltage outside the allowable range |

| A.51 | Overspeed | Servomotor exceeded the allowed rotation speed |

| A.70 | Overload | Output torque exceeded 120% of the rated torque |

| A.73 | Dynamic Brake Overload | Too much energy dissipated during dynamic brake operation |

| A.74 | Inrush Resistance Overload | Inrush current exceeded the limit of the inrush resistor during power-up |

| A.7A | Overheat | Abnormal temperature rise detected in the heat sink |

| A.bF | System Error | Internal control circuit failure detected |

| A.C1 | Runaway Detected | Motor rotated in the opposite direction than commanded |

| A.C2 | Phase Detection Error | Motor’s electrical angle could not be correctly detected |

| A.C3 | Encoder Disconnection | Encoder phase A, B, or S is disconnected or shorted |

| A.d0 | Deviation Counter Overflow | Remaining pulses exceeded the counter’s overflow level (set via Pn505) |