02.07.2025 by Viktor Siebert

Total Failure After Unsuccessful Third-Party Repair Okuma VACIII D6 Drive Unit

A few weeks ago, we received an Okuma VACIII D6 Drive Unit in an alarming condition. The customer – a well-known automotive supplier from the Netherlands – had previously sent the device to another repair company. Instead of a functional unit, he received a completely non-operational drive. The workshop claimed that no spare parts were available for this model and charged nearly €1,000 for the unsuccessful attempt.

Root Cause: Overheating Due to a Faulty Fan

The original fault was clear: “Heat sink overheat“, a well-known issue that becomes more frequent during hot summer days. The cause is something we’ve encountered for over 10 years – defective or aging fans are one of the primary culprits.

In this case, the fan was turning but too slowly, vibrating heavily and producing excessive noise. A clear sign that something was wrong – and one that should be impossible to ignore in a production environment. Continued operation in such conditions puts thermal stress on sensitive components, accelerating wear and leading to premature failure.

Incorrect Repairs and Damaged Traces

Upon opening the unit, we were faced with the consequences of improper repair work:

It appeared the third-party technician had randomly swapped components – including parts that were not faulty – while completely ignoring those that were actually defective. As a result, PCB traces were damaged, and non-compliant, unsuitable components were installed. We essentially had to restore the unit from the ground up.

Our Repair Standard: Prevention, Not Patching

Our repair strategy for the Okuma VACIII D6 is not reactive – it’s preventive and standardized. Over the years, we’ve developed a structured process in which more than 50 known critical components are proactively replaced during each repair.

This includes:

- Replacement of both IGBT modules (e.g., 6MBI100FA-060, MG100J6ES91)

- Complete renewal of all fan units

- Reinforcement or re-routing of critical PCB traces

- Exchange of all thermally or electrically stressed components

- Cleaning, protection and re-coating of sensitive PCB areas

Real-World Load Testing: Only Fully Functional Units Leave Our Facility

Once the repair is complete, every unit undergoes real-world load testing. In this case, the refurbished VACIII D6 was installed into an Okuma LU15 machine and operated under changing loads for several hours.

Our testing protocol includes:

- Monitoring current and torque across all phases

- Real-time thermal sensor tracking

- Validation of all alarm and protection circuits

- Continuous run testing with variable speeds and directions

- Resolver feedback and current control verification

Conclusion: Experience Prevents Total Loss

This case clearly demonstrates how critical genuine expertise, structured processes, and long-term experience are. What others may call “unrepairable” is standard procedure for us – assuming the unit hasn’t been irreversibly damaged beforehand.

If you’re experiencing regular failures or instability with Okuma VACIII D6 / D11 / D22 units – feel free to contact us. We know the weak points. And we fix them – permanently.

Price and Delivery Time for Okuma VACIII D6 Drive Unit

For more information about our Okuma repairs, please click here.

📞 Feel free to contact us if you have any questions regarding your Mitsubishi drive technology. Our experienced team is always ready to provide you with expert advice and support.

Alarm Messages and Troubleshooting exc

| Alarm No. | Alarm Name | Cause / Description | Solution |

|---|

| 1 | P.G. count error | Pulse count from PG exceeds limit | Check or replace PG |

| 2 | Excessive motor speed | Motor speed exceeds allowed maximum | Inspect or replace VAC motor |

| 6 | Resolver error | Resolver does not provide valid signal | Check or replace resolver and cable |

| 10 | Motor cable overcurrent | Overcurrent detected on motor cable | Check motor wiring and motor |

| 12 | Regenerator IGBT short | Short circuit in regeneration section | Replace IGBT, check gate connections |

| 20 | Heat sink overheat | Heatsink temperature exceeds limit | Inspect/replace fan or cooling unit |

| 29 | Slave CPU error | Internal slave CPU error | Replace CPU board |

Component Overview (from table and manual)

| Component | Model | Manufacturer No. | Function |

|---|

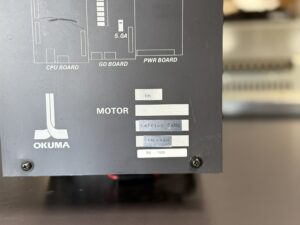

| CPU Board | E4809-045-152-A | 1006-1110 | Controls entire drive unit |

| Gate Drive Board | E4809-045-153-A | 1006-1111 | Controls IGBT modules |

| Power Board | E4809-820-001-A/B | 1006-12.. | Power supply section for motor output |

| IGBT Module | 6MBI100FA-060 (Fuji) | E4443-722-030 | Power transistors |

| Diode Module | MG100J6ES91 (Mitsubishi) | E4443-820-001 | Rectifier and freewheel circuit |

Functional Description

The VACIII D6 is a spindle inverter drive designed to operate VAC motors in Okuma machines. It consists of:

- CPU board: E4809-045-152-A

- Gate Drive Board: E4809-045-153-A

- Power Board: E4809-820-001-A/B

Main Functions:

- Speed and torque control

- Real-time protection monitoring (overcurrent, undervoltage, phase loss, overheating, etc.)

- Resolver input for position feedback

- LED error indicators on device and NC screen