04.06.2025 by Viktor Siebert

The heart of the Mitsubishi Servo Motor HA83C-S is the Tamagawa FA-Encoder OAER5K-1X-3-8-108

Depending on the specific application and control system, the machine manufacturer installs different types of encoders, such as resolver or absolute encoders.

Challenges with Replacement Parts

The mentioned encoder type is no longer available as a new part, and if it can be found, the price exceeds €2,000. Alternatively, used encoders can be found on the market, but there’s a 50/50 chance of their functionality. Issues with these encoders can be particularly deceptive: they often work fine during initial tests but may fail under specific conditions like certain speeds, heat, or mechanical stress.

Real-World Case of a Faulty Encoder

Recently, we experienced a case where a customer sourced a replacement encoder. Initially, the machine functioned without problems, but after two days, both the servo drive and the control unit reported errors. At first, the customer ignored this because the machine seemed to recover shortly after. After three days of downtime, however, the error reoccurred. The customer swapped motors among positions, and the fault migrated accordingly.

Misdiagnosis and Misunderstandings

The customer then filed a complaint regarding the motor, but the seller was skeptical, claiming he had sourced tested components. The seller suggested replacing the servo drive. After this replacement, nothing worked at all, and errors accumulated. This led to a nearly two-month odyssey involving multiple exchanges of drives and motors. Eventually, the customer received his original components back, yet the original issue remained unresolved.

Identifying the Root Cause through Intensive Testing

Only after contacting us and requesting a joint test of both the drive and encoder did we systematically isolate the problem. Initially, the motor ran smoothly, even under load. Extensive tests under varying temperature and vibration conditions were required before our technician could clearly reproduce the fault.

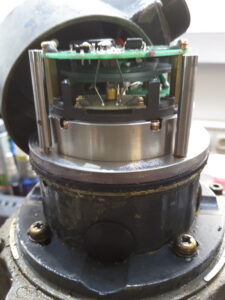

Cause of Fault: Abrasion and Electronic Damage

The precise issue was within the encoder itself: fine dust from motor bearing abrasion entered the encoder, damaging its tiny bearings and settling on the electronics. This caused minimal voltage drops and eventual failures under specific operational conditions (temperature fluctuations, vibrations). Such conditions can permanently damage electronic components or even mechanically destroy the encoder disk.

Repair and Maintenance Actions

After a detailed fault diagnosis, we performed the following overhaul actions:

- Complete disassembly and thorough cleaning of the encoder

- Replacement of damaged bearings and electronic components

- Inspection and realignment of the encoder disk

- Comprehensive electrical tests under simulated operational conditions (temperature and vibration tests)

- Restoration and preventive maintenance of the two servo drives sent in

Following these procedures, the fault was permanently resolved. The customer chose comprehensive overhauls for all components to ensure long-term reliability of the machine.

To mentioned Mitsubishi Motor: Mitsubishi Servo Motor HA83C-S

More details about our Mitsubishi repair services can be found here:

Mitsubishi motor Repair by Industrypart

📞 Feel free to contact us with any questions about your Mitsubishi drive technology.

Our expert team is happy to help!

Technical Specifications – Mitsubishi HA83C-S Servo Motor

| Feature | Specification |

|---|

| Type | HA83C-S |

| Rated Output | 1.0 kW (Continuous) |

| Voltage | 170 V AC |

| Frequency | 100 Hz |

| Rated Current | 4.9 A |

| Rated Speed | 3000 rpm |

| Insulation Class | F |

| Winding Connection | Y (Star) |

| Magnet Type | Permanent Magnet |

| Inverter Voltage | 200 V |

| Maximum Torque | 19 Nm |

| Maximum Current | 28 A |

| Protection Class | IP54 |

| Encoder | OAER5K-1X-3-8-108 (Tamagawa FA-Encoder) |

| Manual Number | Z637260 |

| Country of Manufacture | Japan |

Alarm Codes & Troubleshooting (typical for MR-S12-80A-Z33 drives with HA motors)

| Alarm Code | Description | Troubleshooting Steps |

|---|

| E10 | Overvoltage | Check power supply voltage and braking resistor |

| E32 | Overcurrent | Inspect wiring, connections, and mechanical load |

| E52 | Encoder Error | Check encoder connections and replace encoder if defective |

| E90 | Overheating | Improve cooling and ventilation of motor and drive |

| E70 | Communication Error | Inspect communication cables between drive and control system |