15.08.2025 by Viktor Siebert

Repair Story: Mitsubishi MR-S11-80-E01 Servo Drive Unit

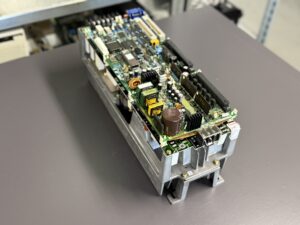

Recently, a Mitsubishi MR-S11-80-E01 Servo Drive Unit arrived at our workshop with a clear error description from the customer. In our in-house test facility, we were able to confirm the reported fault immediately.

Upon closer inspection, we found a typical but severe damage pattern: numerous electrolytic capacitors (electrolytic caps) had leaked. The leaked electrolyte had already caused extensive damage to several circuit boards and had severely corroded multiple copper traces.

One of the affected boards responsible for axis control was so badly damaged that repairing it was no longer economically viable. Fortunately, we maintain a large stock of tested replacement boards, which allowed us to replace the defective unit without delays and continue the repair quickly.

After replacing all defective components, performing a thorough cleaning, and reconstructing the damaged traces, the device was put back into operation. The final load test was passed without any issues, and the servo drive was successfully returned to the customer.

How Customers Can Avoid Similar Damage

Many of these failures can be avoided if devices are overhauled preventively and on time. Electrolytic capacitors have a limited lifespan, which is strongly influenced by temperature, operating hours, and environmental conditions. If they are not replaced in time, leaking electrolyte can cause irreparable damage to nearby components and copper traces.

A preventive overhaul is usually far more cost-effective, as it often involves work only on the component level and avoids the need for expensive PCBs or replacement modules. By replacing critical parts such as capacitors, fans, and relays early, the lifespan of the unit can be extended by many years.

Our Repair Process

- Incoming Inspection

After arrival, the device undergoes a visual inspection to identify obvious damage, corrosion, or missing parts. We also document the condition with detailed photographs.

- Fault Analysis

The unit is connected to our test system to reproduce the reported fault. We log all error messages, unusual noises, temperature changes, and performance deviations.

- Disassembly and Damage Assessment

The boards are carefully removed. Defective and at-risk components are identified, and we assess whether repair or replacement is the more economical option.

- Component Replacement and Trace Repair

Defective parts are replaced with high-quality, original-spec components. Damaged copper traces are reconstructed, solder joints renewed, and weak points reinforced.

- Cleaning

All boards and housing parts are professionally cleaned to remove dust, corrosion residues, and old thermal compound.

Our Testing Process

- Functional Testing

After the repair, the unit is operated in our in-house test environment under realistic conditions to ensure all axes, control functions, and safety mechanisms are working correctly.

- Load Testing

The servo drive is run at full load to check thermal stability, voltage tolerances, and response times.

- Long-Term Testing

The unit is left running for several hours to ensure no intermittent faults occur.

- Final Documentation

All measurements, replaced components, and test results are documented. Upon request, the customer receives a detailed repair report.

What Customers Can Do to Keep Drive Units in Good Condition

While a full overhaul should always be carried out by specialists, machine operators can significantly reduce failures and extend the lifespan of their drives through regular maintenance.

Key measures include:

- Regular Cleaning

Dust and dirt accumulate inside the unit and on heat sinks, reducing cooling efficiency. Cleaning the device environment and air ducts at least once a year is recommended.

- Check and Replace Fans

Fans lose performance over time or fail completely. If you notice unusual noises or reduced airflow, replace them immediately. Faulty fans are a major cause of overheating damage.

- Monitor Control Cabinet Temperature

An ideal cabinet temperature is between 20 and 35 °C. Higher temperatures accelerate the wear of capacitors and other components. If necessary, install additional cooling or improve airflow.

- Plan Preventive Overhauls

Depending on operating intensity, drives should be preventively overhauled every 5–7 years. This includes replacing critical parts such as capacitors, relays, and fans before they fail and cause secondary damage.

- Regular Visual Inspections

Early signs such as discolored PCBs, electrolyte residue, corrosion, or unusual smells should be taken seriously. Acting early saves high repair costs later.

- Track Operating Hours and Usage Profiles

Units running at high loads or in harsh environments often require earlier overhauls than those in light-duty service. Simple usage logging helps with maintenance planning.

To mentioned Mitsubishi Drive: Mitsubishi MR-S11-80-E01 Servo Drive Unit

More details about our Mitsubishi repair services can be found here:

Mitsubishi drive Repair by Industrypart

We regularly repair including boards:

RG201

RG221

RG221C

RG21B

RF312B

BN624A953G51

BN634A229G51

BN634E230G52

📞 Feel free to contact us with any questions about your Yaskawa drive technology.

Our expert team is happy to help!

Technical Specifications

| Parameter | Value |

|---|

| Model | MR-S11-80-E01 |

| Rated Voltage | 200–220 V AC, 3-phase |

| Rated Frequency | 50/60 Hz |

| Rated Power | 8.0 kW |

| Rated Current | approx. 39 A |

| Operating Ambient Temperature | 0–55 °C |

| Storage Temperature | –20 to 70 °C |

| Humidity | 90% RH or less, non-condensing |

| Weight | approx. 12 kg |

| Insulation Class | F |

| Protection Class | IP00 (must be installed inside a control cabinet) |

Operating Environment and Compatible Equipment

The Mitsubishi MR-S11-80-E01 is an AC servo amplifier from the MELDAS MR-S10 series, primarily used in CNC-controlled machine tools.

Typical applications include:

- Milling machines

- Lathes

- Grinding machines

- Machining centers with Mitsubishi MELDAS M300 or similar controllers

Compatible drives and peripherals:

- HA-series servo motors (e.g., HA80, HA90, depending on configuration)

- MELDAS CNC controllers of the S10 generation

- Absolute or incremental encoders

- Optional brake resistors (e.g., MR-RB30 or GZG200W)

Functional Description

The MR-S11-80-E01 is a single-axis AC servo amplifier designed for precise control of servo motors in CNC machines.

Key functions include:

- High-precision position, speed, and current control

- Direct communication with MELDAS CNC controllers

- Regeneration system for energy feedback during deceleration

- Multi-stage protection against overcurrent, overvoltage, overheating, and position errors

- Compatibility with absolute or incremental encoders

- Integrated self-diagnosis and 7-segment error display

Alarm Messages and Troubleshooting

| No. | Alarm Code | Description | Cause | Remedy |

|---|

| 10 | UV | Under Voltage | Supply voltage too low | Check power supply |

| 11 | AE | Axis Error | Incorrect rotary switch setting | Correct setting |

| 12 | ME1 | Memory Error 1 | Defective SRAM or EPROM | Replace component |

| 13 | CE | External Clock Error | Clock signal cable faulty | Check connection |

| 14 | WD | Watchdog Error | CPU process halted | Restart, replace board if needed |

| 15 | ME2 | Memory Error 2 | Data transfer error | Check cable/connection |

| 16 | RD | Rotor Position Error | Defective encoder or wiring | Check/replace encoder |

| 17 | BE | Board Error | Faulty A/D converter | Replace main board |

| 20 | NS1 | No Signal 1 | No signal from encoder | Check cable/encoder |

| 21 | NS2 | No Signal 2 | Missing auxiliary signal | Check connection |

| 22 | NS3 | No Signal 3 | Resolver output faulty | Replace cable or resolver |

Components

| Assembly | Function |

|---|

| Main Board | Controls position, speed, and current |

| Power Module | Drives the servo motor, IGBT stage |

| Power Supply Unit | Converts input voltage |

| Regeneration Circuit | Dissipates energy during braking |

| Axis Control Board | Processes encoder and control data |

| Fan Unit | Cools power modules |

| Terminal Blocks | Power, motor, and control connections |

| Housing | Mechanical protection and mounting structure |