20.10.2025 by Viktor Siebert

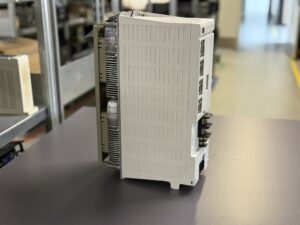

Repair of a Mitsubishi MDS-C1-SP-185 Spindle Drive Unit

The device was sent to us because on Monday morning, after the machine was switched on, the spindle drive remained dark and showed no function.

No LEDs were lit, no reaction a classic case of total failure in the DC link or auxiliary voltage section.

After disassembly, it became clear:

The primary auxiliary voltage circuit was interrupted, and a defect in the startup resistor and relay section prevented the logic power from starting up.

In addition, we found thermally aged electrolytic capacitors in the 24 V supply area and slightly discolored solder joints on the power module (BKO-NC1207 H98 A2-SP-185).

In our laboratory, the unit was completely disassembled, cleaned, and rebuilt using original spare parts from our inventory.

The affected power module was replaced preventively, as well as the IGBT driver section and relays of the startup control.

After reassembly, a complete test run was carried out on our Mitsubishi spindle test bench with simulated motor operation.

During the test, the drive showed a stable DC link voltage of 304 V and responded correctly to speed commands via the interface.

Thermal stability was verified with an endurance test lasting 8 hours.

The unit was then documented, sealed, and returned to the customer together with a test report.

After installation, the customer’s machine started up again without any issues.

We recommend a preventive overhaul every 6–8 years for this series, especially replacing fans, capacitors, and relays to prevent failures like this one.

Preventive Maintenance

| Component | Recommendation |

|---|

| Fans | Replace every 5–7 years |

| Capacitors | Inspect after 7 years |

| Relays & resistors | Check for thermal stress |

| Boards | Inspect for oxidation or cracked solder joints |

Conclusion

The MDS-C1-SP-185 spindle drive is robust but requires periodic preventive service.

Even a minor power relay failure can cause a complete system shutdown.

Professional testing and replacement of power modules and capacitors ensure long-term reliability.

To mentioned Mitsubishi Drive: Mitsubishi MDS-C1-SP-185 Spindle Drive Unit

More details about our Mitsubishi repair services can be found here:

Mitsubishi drive Repair by Industrypart

📞 Feel free to contact us with any questions about your Mitsubishi drive technology.

Our expert team is happy to help!

Technical Specifications

| Parameter | Value |

|---|

| Model | MDS-C1-SP-185 |

| Type | Spindle Drive Unit |

| Manufacturer | Mitsubishi Electric Corporation, Japan |

| Power | 18.5 kW |

| Input Current | 76 A DC 270–311 V |

| Input Voltage (Control) | 1 Ph 200/200–230 V 50/60 Hz 0.2 A |

| Output | 3 Ph 200 V 0–833 Hz 63 A |

| Software | BND553W000A3 |

| Serial | JBA6HG664PE |

| Year | 2006 |

| Manual | BNP-C3000 |

| Protection | CE / TÜV Rheinland |

| Weight | approx. 12 kg |

| Operating Temp. | 0–55 °C |

| Application | Spindle drive for CNC machines (Mazak, Mori Seiki, OKK) |

Components

| Type | Model | Qty |

|---|

| Control Board | RK311B or BN634A817G51 C | 1 |

| Power Board | RL122A-SP or BN638A134G51 C | 1 |

| Power Module | BKO-NC1207 H98 A2-SP-185 | 1 |

Typical Alarms and Causes

| Code | Description | Cause | Remedy |

|---|

| 32 | Power Module Overcurrent | IGBT module shorted, motor short circuit | Check U/V/W, replace IPM |

| 46 | Motor Overheat | Fan failure or dust clogging | Replace fan, clean cooling area |

| 50 | Overload 1 | Excess mechanical load | Inspect bearings, load mechanism |

| 51 | Overload 2 | 95 % continuous current limit exceeded | Reduce load, check duty cycle |

| 42 | Feedback Error 1 | Encoder Z-phase missing | Replace encoder or cable |

| 34 | NC Communication Error | Signal cable fault or wrong setting | Replace cable, check parameters |