17.10.2025 by Viktor Siebert

Weak Under Load Repair of a Mitsubishi MDS-B-V24-3535 Servo Drive Unit

Initial Diagnosis and Observations.

The submitted Mitsubishi MDS-B-V24-3535 Servo Drive Unit exhibited a classic yet demanding fault pattern:

“The drive became weak, and the axes started to shake under load.”

This behavior indicated instability in the current control loop of the servo system. The drive operated, but its dynamic response degraded during acceleration and deceleration. The machine showed unsteady positioning and vibration during load changes a typical sign of weakened power electronics or feedback signal distortion.

Axis vibration under load occurs when the drive can no longer compensate for regulation deviations due to voltage drops in the DC link, weakened gate drive control, or noisy feedback signals.

Technical Function and Structure

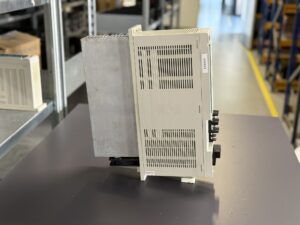

The MDS-B-V24-3535 belongs to the second generation of Mitsubishi’s MDS-B servo drives, widely used in conjunction with MELDAS, M70, and M500 control systems.

It precisely regulates servo motors across multiple axes, ensuring accurate control of torque, velocity, and position.

The drive consists of three main sections:

- Power stage with IGBT modules generates the controlled three-phase voltage for the servo motor.

- Gate driver and control board supervises, switches, and protects the power section.

- DC-link capacitors stabilize the bus voltage during rapid load changes.

Any degradation in these areas directly affects axis behavior. Even minimal timing deviations between actual and target current can produce noticeable oscillations.

Inspection and Fault Analysis

After disassembly, no catastrophic damage was visible, but the power board revealed thermal stress near the IGBT section.

Testing showed voltage dips across the DC link during acceleration, confirming loss of capacitance in the main capacitors.

Oscilloscope analysis revealed irregular gate signals, pointing to aging driver circuits. Furthermore, the connectors between control and power boards showed early oxidation. In high-speed regulation systems, even slight signal delays can lead to vibration and instability.

Root Cause and Weak Points

Laboratory analysis confirmed several contributing factors:

- Reduced DC-link capacitance due to electrolyte aging.

- Degraded gate-driver circuits caused by thermal stress.

- Microcracks in power-module solder joints.

- Signal noise in feedback lines from oxidized connectors.

Together, these caused insufficient current regulation. Under load, the drive could no longer synchronize motor phase currents, leading to shaking and reduced torque.

Repair Process

- Complete disassembly and inspection of all boards.

- Replacement of all DC-link capacitors with 105 °C low-ESR industrial types.

- Renewal of gate driver components including optocouplers and resistors.

- Re-soldering of power paths to remove microcracks.

- Cleaning and refurbishing all connectors.

- Functional testing on Mitsubishi test benches under full load.

After restoration, the servo drive was stable, quiet, and precise. The shaking completely disappeared during dynamic tests.

Preventive Maintenance

Even high-quality Mitsubishi drives lose performance over time due to component fatigue.

To ensure stable operation, we recommend:

- Replace DC-link capacitors every 8–10 years.

- Monitor gate-driver signals when the axis shows instability.

- Clean and protect connectors against corrosion.

- Check thermal balance and fan efficiency regularly.

Preventive maintenance significantly extends the lifespan of servo drives and prevents sudden machine failures.

Conclusion

The repair of the Mitsubishi MDS-B-V24-3535 Servo Drive Unit demonstrates how precision diagnostics and systematic refurbishment restore full performance to aging drives.

What seemed to be a “weak under load” issue turned out to be a combination of several minor but interrelated problems: reduced capacitor strength, weak gate drive, and oxidized signal contacts.

After refurbishment, the unit performed flawlessly again, delivering full torque and precise control.

Once more, it proves that repair instead of replacement is the smarter, sustainable path forward preserving industrial assets and performance where others would give up.

To mentioned Mitsubishi Drive: Mitsubishi MDS-B-V24-3550 Servo Drive

More details about our Mitsubishi repair services can be found here:

Mitsubishi drive Repair by Industrypart

📞 Feel free to contact us with any questions about your Mitsubishi drive technology.

Our expert team is happy to help!

Technical Specifications

| Parameter | Value |

|---|

| Model | MDS-B-V24-3535 |

| Type | AC Servo Drive Unit |

| Input Voltage (DC) | 270–311 V DC, 34 A |

| Input Voltage (AC) | 200/200–230 V, 50/60 Hz, 0.2 A |

| Output | 3 AC, 16/16 A |

| Manufacturer | Mitsubishi Electric Corporation, Japan |

| Software Version | BND513W000A8 |

| Hardware Version | R |

| Manual Reference | BNP-B3890 |

| Serial Number | JBAFW26N66F |

Typical Alarms and Causes

Based on the alarm manual (see uploaded document), the following errors frequently occur in this series:

| Code | Description | Explanation | Cause | Solution |

|---|

| 3A | OC (Overcurrent) | Motor overcurrent | Short circuit or defective IGBT module | Inspect the power section |

| 3B | PMOH (Power Module Overheat) | Overheating of the IPM module | Fan failure or heat accumulation | Check fan and heatsink |

| 42 | FE1 (Feedback Error 1) | Encoder signal error | Disconnection or defective encoder | Inspect cables and connectors |

| 44 | OL1 (Overload 1) | Overload during operation | Excessive load or faulty motor brake | Reduce load, check mechanical system |

| 32 | POF (Power Module Overcurrent) | Power module fault | Defective transistor module | Replace the module |