09.07.2025 by Viktor Siebert

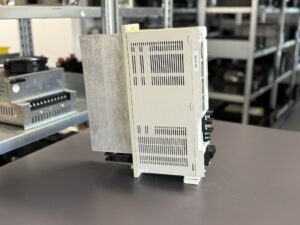

Customer with Deckel Maho DMC 100V Machines Chooses Repair Over Replacement Mitsubishi MDS-B-V2-3535 Servo Drive

A manufacturing company based in Munich is still operating several Deckel Maho machining centers of the DMC 100V series. Although these machines have been in use for many years, they are still in excellent condition according to the customer. In general, the customer is very satisfied with machines from DMG, praising their longevity and reliability.

Spare Parts Supply Becomes a Challenge for Older Machines

As with many aging systems, sourcing spare parts has become increasingly difficult. New OEM components are rarely available, and the market is dominated by used or refurbished parts, often offered at high prices. The customer was no longer interested in such options. In the past, he had repeated negative experiences with used modules. Despite bold promises from sellers, the reality was disappointing. Modules often failed shortly after installation or did not work at all. Warranty coverage was limited, and the risk was ultimately borne by the buyer.

While the original manufacturer still provided high-quality parts, the customer was no longer willing to pay the corresponding price. He emphasized that for new machines, he still relies entirely on the OEM, but when a machine has been in use for several years, such investments are no longer economical.

Recommendation by Maintenance Technician Leads to New Contact

The customer was referred to us by his trusted maintenance technician. We were already familiar with both the machine type and the modules used inside. At our facility, we have set up a test environment that replicates real machine conditions. This allows us to test the drives not only for basic functionality but also under realistic operational scenarios. This is particularly important with these modules, as many issues only appear under load and motion.

Fault 17 on MDS-B-V2-3535 Servo Drive Detected

In this case, the faulty module was an MDS-B-V2-3535 drive that controls two axes. It displayed error code 17 during startup. This code refers to an internal A/D converter failure in the current detection circuit. It indicates that the current sensors or logic circuits are no longer delivering valid signals, likely due to defects in the control or power board.

Since we are familiar with this error from previous cases, we were able to offer a flat-rate repair immediately. It is important to mention that most of our repairs are offered at a fixed price. For our customers, this ensures price transparency and planning reliability. Our flat rates are not arbitrary but are based on a large number of completed repairs and extensive experience. Only in rare cases do we need to increase the price, such as when a unit has been previously repaired by another provider or shows signs of water or fire damage.

Fast Return After Preventive Overhaul

The repair took less than five working days. The customer received the device fully and preventively overhauled, shipped back via UPS. The machine is now running without issue. The customer himself concluded that repair was significantly more cost-effective than buying a replacement. He has already packed the next servomotor and is preparing it for shipment.

Our Preventive Overhaul Process for Servo Drives

Each repair includes a complete preventive overhaul. This means we do not just replace the defective parts but also systematically address all known weak points. We continuously analyze the most common failure patterns for each device type and maintain an internal list of components that are replaced as standard. Depending on the model, up to 50 parts are routinely exchanged, including:

- Aged electrolytic capacitors

- Burnt or unstable relays

- Corroded or cracked connectors

- Temperature sensors and fan units

- Power regulation modules

Every unit is then tested under realistic load conditions in our test bay. We monitor behavior under temperature, load, and dynamic conditions. Only after successfully passing all functional and stress tests is the device released and shipped.

To mentioned Mitsubishi Drive: Mitsubishi MDS-B-V2-3535 Servo Drive

More details about our Mitsubishi repair services can be found here:

Mitsubishi drive Repair by Industrypart

📞 Feel free to contact us with any questions about your Yaskawa drive technology.

Our expert team is happy to help!

Technical Specifications

| Parameter | Value |

|---|

| Type | MDS-B-V2-3535 |

| Power (Rated/Peak) | 3.5 / 3.5 kW |

| Input | DC270–311 V, 34 A |

| Power Supply | 1-phase 200–230 V, 50/60 Hz, 0.2 A |

| Output | 3-phase 155 V, 0–240 Hz, 16 A |

| Standard | DIN VDE0160 |

| Manual No. | BNP-B3759 |

| Dimensions (H×W×D) | Approx. 380×90×300 mm |

| Weight | Approx. 6 kg |

| Cooling | Internal fan cooling |

Internal Components

| Component Name | Board Identification | Qty |

|---|

| Control Board | RK111C or BN638B306G51 | 1 |

| Control Board | RK111B-12 or BN634A815G51 D | 1 |

| Power Board | RK122B-V2-3535 or RK122C-V2-3535 | 1 |

| Power Section | Not specifically identified (likely integrated) | 1 |

Alarm and Error Table for Mitsubishi MDS-B-Vx Servo Drives

| Alarm No. | Name | Meaning | Possible Causes | Solutions / Actions |

|---|

| 03 | Overcurrent | Excessive current detected in power module | Motor short circuit, cable fault, defective IGBT | Check motor and cable, test or repair the drive module |

| 05 | Regenerative Error | Regenerative energy cannot be dissipated properly | Brake resistor faulty, poor wiring, load too high | Check resistor, wiring connections, verify resistance value |

| 07 | Overvoltage | DC link voltage too high | Input voltage too high, incorrect supply or missing reactor | Verify mains voltage, add reactor if needed, check CV unit input |

| 08 | Undervoltage | DC link voltage too low | Power supply interruption, defective CV power unit | Check incoming power supply, test or replace MDS-B-CV unit |

| 11 | Memory Error | EEPROM or internal memory access error | Damaged control board, data corruption | Inspect control board, reinitialize or replace if necessary |

| 17 | AD Converter Error | Failure in current detection A/D converter | Faulty sensors on power board, initialization failure | Check control and power boards, perform repair |

| 50 | Overload 1 (OL1) | Long-term overload detected | Motor consistently overloaded, incorrect parameter settings | Review load and settings, adjust parameters, check sizing |

| 51 | Overload 2 (OL2) | Instantaneous overload (e.g., collision or sudden torque spike) | Axis crash, excessive inertia | Check mechanics, reduce inertia, fine-tune parameters |

| 58 / 59 | Load Error / Disturbance | Significant deviation between actual and expected torque | Collision, blocked axis, excessive friction | Inspect mechanics, review collision detection settings, check torque limit |

| 70 | Overspeed | Motor speed exceeds permitted limit | Feedback error, wrong settings, mechanical uncoupling | Verify encoder, inspect parameters, check mechanical connections |

| 79 | Brake Error | Brake output fault or mechanical brake malfunction | Stuck brake, faulty wiring | Check brake coil and output on CN20, inspect mechanical brake |

| 9B | Pole Shift Warning | Motor pole alignment not valid after startup | MDS-B-MD unit not recognizing magnetic pole position | Perform DC excitation again, check SV028 (Pole Shift value) |