09.10.2025 by Viktor Siebert

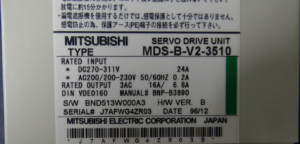

Repair Story: Mitsubishi MDS-B-V2-3510 Servo Drive Unit with Overcurrent Error 32

This drive was sent in for preventive overhaul. During the initial inspection, it refused to power up. Only after controlled heating by our technician did it start responding, a typical sign of aged components in the power or reset circuit.

Once powered, the unit was connected to our Mitsubishi test bench. During high-speed travel, the motor began to stutter and triggered Error 32 Overcurrent.

After contacting the customer, it became clear that the machine had not been switched off for months. The operator had even reduced feed rates and stopped machining heavy parts to avoid triggering the fault.

Inspection revealed:

- Cracked and aged electrolytic capacitors

- Weak solder joints on the power board

- Heat-damaged driver ICs

- Fan operating at reduced speed

The repair included:

- Complete replacement of capacitors and IGBT module

- Reflow of critical solder points

- Cleaning and thermal restoration of the power stage

- Full functional test and 24-hour burn-in under temperature variation

The repaired drive passed all tests successfully and was reinstalled by the customer.

Machine operation returned to normal, with full power and stability.

This case shows the clear value of preventive service, especially for discontinued models.

Preventive Measures

- Replace capacitors every 5–7 years

- Inspect and clean fan annually

- Check all connectors and cables for oxidation

- Keep ventilation paths clear

- Maintain cabinet temperature below 40 °C

- Perform insulation tests during service

- Avoid continuous operation without power cycles

Conclusion

The Mitsubishi MDS-B-V2-3510 is a reliable and long-lasting servo drive.

Proper maintenance and periodic refurbishment ensure decades of stable machine operation.

This case highlights how expert repair can restore even heavily aged drives, ensuring sustainability and minimizing downtime.

To mentioned Mitsubishi Drive: Mitsubishi MDS-B-V2-3510 Servo Drive

More details about our Mitsubishi repair services can be found here:

Mitsubishi drive Repair by Industrypart

📞 Feel free to contact us with any questions about your Mitsubishi drive technology.

Our expert team is happy to help!

Technical Specifications

- Input Voltage (DC): 270–311 V

- Input Voltage (AC): 200/200–230 V, 50/60 Hz

- Input Current: 24 A (DC) / 0.2 A (AC)

- Output: 3-phase AC

- Output Current: 16 A / 6.8 A

- Cooling: Forced air (integrated fan)

- Control: Pulse and torque control, serial CNC communication

- Standard: DIN VDE0160

- Weight: approx. 8.5 kg

- Dimensions (W × H × D): approx. 90 × 300 × 250 mm

- Type: Dual-axis servo amplifier

Operating Environment & Compatible Devices

The MDS-B-V2-3510 is used in mid-range CNC machine tools such as machining centers, lathes, and milling machines.

Typical manufacturers include DMG MORI, Mazak, OKK, and Mitsubishi (M70, M500, M700 controllers).

Common axis applications:

- X, Y, and Z axes

- Tool changers or positioning axes

Compatible servo motors: Mitsubishi HA- and HF-series (e.g., HF103, HA80NCB, HF153).

Functional Description

The unit converts CNC command signals into precisely regulated current and voltage for servo motors.

It operates with a three-loop control structure (current, speed, position) and provides comprehensive protection against overcurrent, overvoltage, overheating, and communication faults.

Communication with the CNC is handled via serial encoder interfaces.

The drive continuously monitors motor current, position, and temperature, shutting down instantly in case of abnormal conditions.

Alarm Messages

| Code | Description | Cause | Solution |

|---|

| 12 ME | Memory Error | SRAM/FLROM fault | Check or replace CPU board |

| 18 WAT | Initial Communication Error | Absolute encoder data error | Check encoder cable or initialize data |

| 1B SCPU | Sub-CPU Error | Logic processor fault | Reset drive, inspect CPU bus |

| 1C SLED | LED Error | Encoder LED malfunction | Replace LED sender |

| 20 NS1 | No Signal Detected | No A/B phase signal | Check encoder connection |

| 31 OS | Overspeed | Speed limit exceeded | Check mechanics and tuning |

| 32 OC | Overcurrent | Excessive output current | Check IPM module, replace capacitors |

| 3B PMOH | Power Module Overheat | IPM temperature too high | Check fan, cooling, thermal paste |

| 46 OH1 | Motor Overheat | Motor temperature exceeded | Check ventilation and cooling |

| 82 NSP | Power Supply Error | DC bus voltage issue | Inspect power supply and DC link |

Key Components

- Control Board signal processing and communication

- Power Module (IGBT) DC-to-AC power conversion

- DC-Link Capacitors smoothing DC bus voltage

- Fan Unit forced cooling

- Sensor/Signal Board – encoder and feedback management