24.11.2025 by Viktor Siebert

Repair of a Mitsubishi HF-H204S Servo Motor with Encoder Failure OSA105S5 From a Traub Machine

The motor was sent to us because it repeatedly failed during machining and the MDS-DH-V1-80 displayed overload alarms. The customer described that the machine sometimes ran normally for hours, but during demanding programs or increased cutting volumes, the axis would suddenly stop. The drive reported overload or feedback errors, and the machine only continued after a reset. These symptoms already suggested a feedback-related problem because encoder failures have a direct impact on current regulation and position monitoring.

During the initial inspection we found the typical oil and dust film expected in metalworking environments. The shaft could be rotated manually, but with a slight roughness. After disassembly, early indications pointed toward an encoder problem. The OSA105S5 behaved inconsistently, its signal was unstable, and during test operation we saw communication dropouts. Exactly this behavior can cause overload alarms, because when the feedback signal collapses even briefly, the drive interprets this as an abnormal load event and shuts down for protection.

Further teardown revealed the complete damage pattern. One bearing near the encoder side had worn out and caused micro-vibrations transmitted directly to the encoder disc. These vibrations, combined with contamination from coolant mist and fine chips, led to partial moisture ingress into the encoder housing. The optical section was affected and the absolute position data occasionally deviated. This resulted in the drive detecting incorrect load conditions, triggering overload and excessive-error alarms.

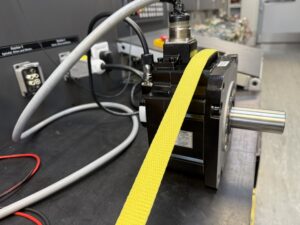

The motor was fully cleaned, the winding inspected and the insulation values measured. Both bearings were replaced, the shaft surfaces polished, and all seals renewed. The OSA105S5 encoder was replaced with a new compatible unit. After replacement, the encoder was initialized, the zero point set, and the multiturn data verified.

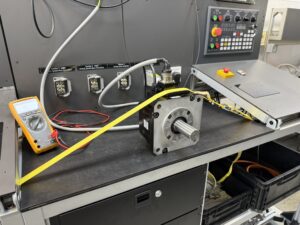

We then proceeded with extensive test-run procedures on our dedicated servo test bench. The motor was connected to an MDS-DH-V1-80 drive and operated under different load points and speed ramps. In the video embedded in the blog, one of our technicians explains the procedure in detail. He demonstrates how the motor is tested in no-load conditions, under dynamic ramps, and with simulated load cycles. The main focus lay on stable encoder feedback because this was the critical factor in the customer’s machine.

After several hours of operation, the motor showed completely stable behavior. No feedback errors, no overload alarms, and no irregularities in the encoder signal. All measurements were recorded and archived for traceability.

The preventive overhaul ensures long-term reliability. With new bearings, renewed seals, and a new encoder, the motor is prepared for continuous operation under demanding load conditions. In Traub machines, where heavy cycles and rapid feed changes are common, this stability is essential for maintaining machining accuracy and productivity.

Preventive Measures for the Customer

- clean and inspect all connectors regularly

- inspect encoder cable every six months

- monitor vibration and unusual noise

- replace shaft seals every 2 to 3 years

- avoid continuous maximum-load operation

- protect the motor environment from coolant mist

- recheck drive parameters after encoder replacement

Conclusion

The failure of the HF-H204S was caused by a worn bearing and a damaged encoder affected by moisture and vibration. After full reconditioning and encoder replacement, the motor performed flawlessly during long-term tests. Preventive maintenance would have avoided downtime and significantly reduced the cost of the fault.

To mentioned Mitsubishi Motor: Mitsubishi HF-H204S AC Servomotor

More details about our Mitsubishi repair services can be found here:

Mitsubishi motor Repair by Industrypart

📞 Feel free to contact us with any questions about your Mitsubishi drive technology.

Our expert team is happy to help!

Technical Specifications

| Parameter | Value |

|---|

| Voltage | 3AC 381 V |

| Current | 3.5 A |

| Power | approx. 2.0 kW |

| Rated speed | 2000 r/min |

| Type | AC Servo Motor HF-H204S |

| Encoder | Mitsubishi OSA105S5 |

| Brake | None |

| Cooling | Self-cooling, closed housing |

| Manufacturer | Mitsubishi Electric |

| Machine type | Traub CNC machine |

| Compatible drive | MDS-DH-V1-80 |

| Serial number | 7007008002086 |

| Origin | Japan |

| Manual reference | MDS-D/DH Series Instruction Manual |

Operating Environment and Compatible Devices

The Mitsubishi HF-H204S is used in high-performance machine tools, typically in turning centers, milling machines, or combined machining systems. In this case it came from a Traub machine, an industrial environment with strong cutting forces, fast feed movements, and long daily duty cycles.

It is usually operated with:

- MDS-DH-V1-80 servo drive unit

- General MDS-DH-V1 series

- Mitsubishi CNC controllers of the M700/M800 generation

- OSA105S5 absolute encoder interface

The typical environment includes high dynamics, varying cutting forces, and precise positioning requirements. Motors of this class rely on robust bearings, stable encoder feedback, and consistent thermal behavior.

Functional Description

The HF-H204S is a high-torque servo motor from the Mitsubishi HF-H series. It provides fast and accurate positioning and feed movements. The OSA105S5 encoder supplies position, speed, and absolute data directly to the MDS-DH-V1-80 drive.

Its main functional characteristics include:

- precise dynamic positioning

- stable absolute feedback

- high continuous output due to strong copper windings

- shock resistance for harsh machining environments

- thermal monitoring via internal sensors

- integrated protective functions through the drive (overload, overcurrent, encoder communication faults)

The encoder plays a critical role. If the drive receives unstable feedback, it immediately triggers protective actions such as overload, excessive error, or feedback alarms.

Alarm Messages and Troubleshooting

| Code | Description | Cause | Solution |

|---|

| 50 | Overload 1 | mechanical resistance, encoder fault | inspect bearings and encoder |

| 51 | Overload 2 | 95 percent load for longer than 1 second | reduce load, review parameters |

| 52 | Excessive error 1 | actual vs theoretical position mismatch | inspect encoder, mechanics |

| 46 | Motor overheat | high temperature or sensor error | inspect airflow, reduce load |

| 23 | Excessive speed error | command vs feedback mismatch | encoder instability, bearing issues |

| 3A | Overcurrent | sudden load change or encoder error | inspect cable, feedback, bearings |

| 41 | Feedback error 3 | missing Z-phase | encoder defective |

| 42 | Feedback error 1 | feedback signal incorrect | cable or encoder issue |

| 2B | Main-side detector error | encoder communication failure | replace encoder |

| 25 | Absolute position lost | absolute memory lost | re-initialize zero point |

| 18 | Initial communication error | communication unstable | cable or encoder failure |

Components

| Component | Label | Function | Test Notes |

|---|

| Stator | HF-H204S winding | generates magnetic field | insulation and resistance test |

| Rotor | Permanent magnet rotor | torque generation | visual and runout test |

| Encoder | OSA105S5 | position and absolute feedback | check signal image, initialize |

| Connectors | Power and encoder | interface to drive | visual inspection, continuity |

| Seal | Shaft seal | protects internals from oil | inspect for wear |

| Bearings | Front and rear | stable rotation | check noise, heat, play |

| Housing | Cast aluminum | cooling and structural support | cleaning and crack inspection |