03.06.2025 by Viktor Siebert

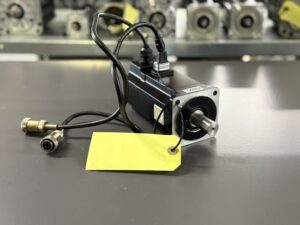

Mitsubishi HC-MF73-S15 AC Servo Motor – Repair Despite Total Damage

This motor frequently suffers from a damaged seal, allowing oil and coolant to enter the motor’s interior. The first components to fail are typically the ball bearings. The resulting metal dust from abrasion spreads onto the rotor and deteriorates its insulation. The insulation corrodes over time, eventually rendering the rotor unusable. At that point, only a donor part can help.

The oil-coolant mixture continues to spread, reaching the encoder and destroying the encoder disk.

The Economic Challenge

Normally, such a motor is considered beyond repair. The machine manufacturer offers replacement motors at a price of €4,900. This is a painful cost for users, especially since these motors are used in specific machines that are still highly valuable. As a result, many users reluctantly replace the motors.

One tool manufacturer contacted us with the question: “What can we do?”

He operates hundreds of these machines and said: “I spend nearly €100,000 a year on motor repairs. The motors are replaced—and quite often, the servo amplifier is also damaged. Then there are the downtime costs, which are impossible to quantify.”

The customer has an in-house maintenance team that maintains the machines and replaces parts according to standards. However, sourcing spare parts is a significant disadvantage—it is costly and often tied to the machine manufacturer’s technicians. Just the travel costs are billed at €1,000. This is outrageous, especially considering the machines are not even that old.

He spoke of earlier years, when quality was better. Some of his older machines have been running for over 20 years without major failures.

Our Solution for the Customer

We were able to implement an effective package for this customer:

- Motor overhauls at our facility:

In most cases, the repair cost is less than 30% of the new purchase price.

- Stocking critical components:

The customer receives high-quality, fully refurbished units from us with a service life close to that of new devices.

- Training the customer’s maintenance staff:

We trained his in-house team on preventive measures to extend the lifespan of motors and drives.

The Result After Three Years

Since starting the collaboration, the customer has reduced his costs by 50%.

He reported that the stress has also decreased significantly—his staff are more relaxed, the machines run reliably, and downtime is minimal.

What Can Be Done to Prevent Total Motor Failure?

- Regular inspection of motors, especially seals and ball bearings.

- Responding promptly to machine error messages.

- Regular cleaning of the motors.

Even in Severe Cases, We Have a Solution

Even when a motor seems beyond economic repair, we can help.

With access to spare parts, expert know-how, and defined repair standards, we’re able to restore many motors cost-effectively.

This particular motor contains a Mitsubishi encoder OBA17-052, which we can replace and program to match the motor precisely.

To mentioned Mitsubishi Motor: Mitsubishi HC-MF73-S15 AC Servo Motor

More details about our Mitsubishi repair services can be found here:

Mitsubishi motor Repair by Industrypart

📞 Feel free to contact us with any questions about your Mitsubishi drive technology.

Our expert team is happy to help!

Technical Specifications

| Technical Specification | Value |

|---|

| Model Number | HC-MF73-S15 |

| Motor Type | AC Servo Motor |

| Input Voltage | 3-phase AC 117 V |

| Input Current | 5.2 A |

| Output Power | 750 W (0.75 kW) |

| Rated Speed | 3000 rpm |

| Insulation Class | Class B |

| Weight | 3.6 kg |

| Standard | IEC60034-1 ’99 |

| Country of Manufacture | Japan |

| Manufacturer | Mitsubishi Electric |

| Encoder | OBA17-052 |

Typical Faults and Recommended Actions

Based on common issues with the HC-MF73-S15 servo motor, the following measures are recommended:

- Motor runs unevenly or vibrates:

- Test motor operation by temporarily replacing it.

- Check all cable connections.

- Disconnect motor from coupling or belt and test at various speeds.

- Check or replace the drive unit.

- Perform insulation testing on the motor.

- Conduct a visual inspection of the motor.

- Inspect and clean the encoder chamber if contaminated.

- Check encoder signals.

- Motor feels stiff or the controller reports overload:

- Disconnect motor from coupling or belt and test at different speeds.

- Disconnect motor cables and manually turn the shaft.

- Check insulation resistance and for possible winding faults.

- Inspect the encoder.

- Controller reports encoder error:

- Inspect and clean the encoder chamber.

- Check encoder signals.

- Replace the encoder if necessary.

These actions help identify and resolve the most frequent problems effectively.