02.09.2025 by Viktor Siebert

Restored to Precision: Overhauling a Damaged Mitsubishi HA43NCB-S Servo Motor with OSA104SA

The HA43NCB-S servo motor arrived at our repair facility in a severely contaminated state – covered in oil, dust, and machine residue. The customer reported a recurring 5A encoder error, especially during machine warm-up cycles. The motor had been operating continuously in a CNC machining center and had not undergone preventive maintenance in several years.

Initial Diagnosis:

Upon connection to our MDS-C1-V2-1005 test bench, the motor immediately threw a 5A error. The oscilloscope revealed intermittent encoder signal dropouts every 200–300 milliseconds, suggesting internal moisture ingress or contact oxidation. A mechanical hum was also noticeable.

Disassembly & Cleaning:

Once opened, we discovered heavy oil contamination inside the stator, encoder housing, and connector assemblies. The shaft seals had failed, allowing oil mist to migrate deep into the motor. Bearings showed signs of wear and sticky residue. We proceeded with a multi-stage cleaning process:

- Full emulsion bath cleaning

- Manual brushing of stator and rotor

- Oven drying at 60 °C for 8 hours

- Ultrasonic cleaning of connector pins

Rebuild Process:

- Bearings: replaced with high-grade sealed units

- Shaft seals: upgraded to enhanced oil-resistant versions

- Connectors: cleaned and re-crimped

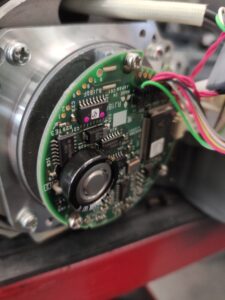

- Encoder: replaced with a new OSA104SA unit

- Encoder setup: initialized, programmed and adjusted

Final Testing:

On the test bench, the motor passed all diagnostics:

- Encoder signal quality verified via scope

- No alarms under load

- Full thermal cycle performed

- No encoder drift or feedback errors

Our detailed test protocol included:

- Feedback analysis

- Insulation testing

- Vibration measurement

- Load ramp-up & emergency stop simulation

The motor is now in like-new condition and ready for long-term service.

Causes of Encoder or Motor Failure

- Thermal cycling leads to condensation and corrosion inside the encoder

- Oil mist penetrates through aged shaft seals

- Vibration damages encoder internals or connector pins

- Aging components especially after 10+ years of continuous use

- Loose cables cause intermittent feedback errors

Failures often begin sporadically, with temporary encoder errors. Over time, the frequency of errors increases until the motor no longer functions reliably.

Preventive Tips for Customers

- Keep the motor dry and clean avoid exposure to mist and coolant

- Inspect cables and connectors regularly

- Avoid rapid temperature changes

- Schedule preventive overhauls every 3–5 years

- Replace encoders proactively if signs of drift appear

- Use original shaft seals and precision bearings

- Document any abnormal sounds, vibrations or alarms

Further information such as pricing and delivery times for the mentioned device:

Mitsubishi HA43NCB-S AC Servo Motor mit Encoder OSA104SA

Erwähnte Mitsubishi MDS-C1-V2-1005 Servo Drive Unit

You can find more information about our Mitsubishi repair services here.

📞 Feel free to contact us if you have any questions regarding your drive technology. Our experienced team is always available to support you with advice and assistance.

Device Data

| Specification | Value |

|---|

| Model | HA43NCB-S |

| Manufacturer | Mitsubishi Electric |

| Voltage | 170 V (3AC) |

| Current | 2.8 A |

| Power | 0.5 kW |

| Frequency Range | 0–100 Hz |

| Rated Speed | 3000 rpm |

| Rated Torque | 1.6 Nm |

| Protection Class | IP54 |

| Weight | 10 kg |

| Power Factor | 98 % |

| Insulation Class | Class F |

| Max Ambient Temperature | 40 °C |

| Encoder | OSA104SA (serial, absolute) |

Operating Environment & Compatible Equipment

The HA43NCB-S is a durable AC servo motor designed for precision positioning and control in CNC machinery. It is typically used in machining centers, milling machines, or drilling equipment especially for vertical or axis-critical applications.

Compatible Mitsubishi Servo Drives:

- MDS-C1-V2-1005

- MDS-B-V2-1005

Common Applications:

- Axis motors in Mazak, Mori Seiki, Kitamura machines

- Servo systems using serial absolute encoders (OSA104SA)

- Machines requiring stable absolute positioning after restart or shutdown

Functional Description

The HA43NCB-S is a 3-phase AC servo motor with medium-inertia characteristics and integrated OSA104SA encoder. This serial absolute encoder enables high-precision closed-loop control, making the motor suitable for vertical axis applications. The motor is fanless and IP54 protected, offering long-term reliability in industrial settings.

Alarms and Troubleshooting

| Alarm Code | Description | Cause | Solution |

|---|

| 5A | Encoder error (position error) | Faulty OSA104SA or cable/connector | Replace encoder, check wiring, reinitialize |

| 25 | Absolute position error | Battery low or uninitialized encoder | Check/replace battery, perform encoder initialization |

| 20 | No encoder signal | Disconnected or damaged cable | Inspect and replace connector and encoder cable |

| 03 | Overvoltage | Faulty power supply or return line | Check input voltage and ground |

| 08 | Overtemperature | Dirty or blocked motor cooling path | Clean motor, check bearings |

| 32 | Overcurrent | Bearing seizure or winding short | Replace bearings, check motor insulation |

| 50 | Overload | Mechanical resistance too high | Check load and mechanical transmission |

| 70 | Position deviation | Encoder drift due to vibration or contamination | Check encoder signal and mounting conditions |

| A0 | Internal communication fault | Encoder board error | Replace encoder board or encoder |

| FE | Feedback error | Poor signal quality | Measure signal with oscilloscope, verify shielding |

Components

| Component | Description |

|---|

| Rotor | Internal rotor |

| Stator | Coil windings |

| Encoder | OSA104SA (serial absolute encoder) |

| Bearings | Precision ball bearings |

| Housing | Aluminum enclosure (IP54) |

| Connectors | Power and encoder connectors |

| Seals | Shaft seals against oil ingress |