13.05.2025 by Viktor Siebert

Repair Report and Device Information: MDS-DH-V1-40 Mitsubishi Servo Drive Unit

A Real-World Case from Our Workshop

Recently, we received an MDS-DH-V1-40 servo amplifier from Mitsubishi for repair. The customer was not a typical machine operator, but a procurement company acting as a strategic purchasing partner for major corporations. Since they operate on behalf of third parties and bear responsibility towards their clients, they had specific expectations for transparency and quality.

Even before we began the repair, the client wanted detailed information about our processes: Do we work with checklists? Do we document every step? Can the customer trace exactly what was done? Our answer: Absolutely.

After the repair, the client received a fully documented workflow, including a test report and checklist. The device passed all tests, was shipped back, and is already in use again. The customer was so satisfied that this single job led to a new long-term partnership.

Checklists and Process Documentation

Our repair procedures are based on comprehensive checklists. These allow for systematic fault analysis and complete traceability of every step taken.

Why Checklists Matter:

- Transparency – The customer receives a detailed report of the repair.

- Quality Assurance – Internal control through systematic checks.

- Traceability – Every step is documented and reproducible.

Typical Workflow:

- Visual inspection and condition assessment

- Functional testing and fault analysis

- Repair according to manufacturer specifications

- Final testing with full documentation

- Delivery of records to the customer

Upon request, we provide sample checklists and repair reports (motors and drives).

To mentioned Mitsubishi Drive: Mitsubishi AC Servo Drive Unit MDS-DH-V1-40

More details about our Mitsubishi repair services can be found here:

Mitsubishi drive Repair by Industrypart

We regularly repair similar models, including:

MDS-D-V1-40

📞 Feel free to contact us with any questions about your Yaskawa drive technology.

Our expert team is happy to help!

Device Description and Technical Specifications

Type: MDS-DH-V1-40

Series: Mitsubishi MDS-DH

Input: 3-phase 380–480 V AC, 2.9 A

Output: 3-phase 380–480 V, 5.9 A, 0–400 Hz

Control voltage: 24 V DC, 0.9 A

Software version: VER.A

Year of manufacture: ca. 2014

Power rating: 2.0 kW

Operating Environment and Applications

The MDS-DH-V1-40 servo unit is part of Mitsubishi’s M700/M70 CNC systems and is commonly used in high-speed CNC machines such as machining centers and lathes.

Environmental Conditions:

- Operating temperature: 0 to 55 °C

- Humidity: up to 90% (non-condensing)

- No corrosive or flammable gases

- Protection against dust, oil mist, and conductive contaminants

Functional Overview

This servo amplifier controls an AC servo motor, managing position, speed, and torque. Communication is handled optically via the CNC interface. The unit features multiple protections, including overcurrent, overvoltage, motor overheat, and communication errors.

Key Functions:

- Fully closed-loop control

- Synchronized speed control

- Temperature monitoring for motor and drive

- Safety features like emergency stop and collision detection

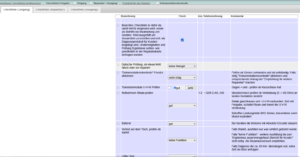

Alarm Messages and Troubleshooting

Here is an excerpt of the most relevant alarms and solutions for the MDS-DH-V1-40:

Alarm 10: Bus voltage too low

Cause/Solution: Check power supply, measure input voltage

Alarm 12: Memory error

Cause/Solution: Recommend replacing the unit

Alarm 16: Magnetic pole initialization error

Cause/Solution: Verify parameter SP118 / reinitialize pole position

Alarm 24: Ground fault detected

Cause/Solution: Inspect motor cables and insulation

Alarm 31: Motor overspeed

Cause/Solution: Review parameters / check mechanical load

Alarm 46: Motor temperature too high

Cause/Solution: Check cooling system / reduce load on motor