06.02.2026 by Viktor Siebert

Repair of a HAAS Servo Amplifier 4015P-B / 32-4015P-B

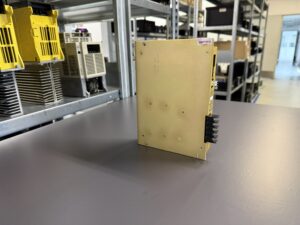

The 4015P-B or 32-4015P-B HAAS Servo Amplifier arrived with the clear fault description “no function”. In practice, this usually means an immediate production stop for the operator: the axis cannot be enabled, the machine remains in alarm state, or it does not start up at all. Especially on machines from Haas Automation, which are often operated in multi-shift production, this represents a critical situation.

Already during the incoming inspection, it became apparent that the amplifier showed no signs of life. No response, no proper initialization, no feedback to the control system. Such fault patterns rarely occur suddenly without any prior history. In many cases, thermal stress, aging of electronic assemblies, or environmental influences play a decisive role. This is exactly where our structured diagnostic process begins.

After the documented visual inspection, the electrical pre-test was carried out outside the machine. In this step, we systematically check whether the amplifier is basically responsive and whether protective functions are already triggered during power-up. In this particular case, it quickly became clear that an internal defect was present. We deliberately do not go into specific component names. What matters is understanding the root cause: a safety-relevant internal functional block was no longer operating correctly, which resulted in the complete failure of the amplifier.

The next step was the professional repair. Here, we do not limit ourselves to merely fixing the immediate fault, but consistently pursue a preventive repair approach. This means that known weak points are inspected and proactively refurbished in order to prevent subsequent damage or renewed failures in the foreseeable future. This is particularly important for HAAS servo amplifiers, as they are directly connected to the machine’s DC bus and operate under high electrical and thermal loads.

After completion of the repair, the amplifier was first tested on our control system simulation test bench. On this setup, we simulate communication with the MOCON board, monitor current consumption, response behavior, and protection functions, and carry out defined load tests. This step ensures that the unit is electrically stable and reacts correctly to control signals.

What clearly sets us apart from many other repair approaches is the additional practical test. We do not test HAAS servo amplifiers only “on the bench”, but in an original HAAS machine, under real conditions and with load. Only in this way can it be ensured that the amplifier not only works in theory, but also reliably delivers its performance in interaction with the original control, motor, and mechanics. Only after this machine-level test is a unit released by us.

Finally, every repaired unit passes through our internal checklists. These include incoming documentation, repair approval, electrical measurement values, thermal behavior, test duration, and final functional evaluation. This structured procedure ensures traceability, quality assurance, and long-term operational reliability for the customer.

Especially with older but proven HAAS machines, it becomes clear time and again that a professional repair with a preventive approach is economically sensible and sustainable compared to an unplanned replacement. After completion of all tests, the repaired 4015P-B servo amplifier operates reliably again and is ready for many more operating hours in real production environments.

To mentioned HAAS Drive: HAAS Servo Amplifier 4015P-B / 32-4015P-B

More details about our HAAS repair services can be found here:

HAAS drive Repair by Industrypart

📞 Feel free to contact us with any questions about your HAAS drive technology.

Our expert team is happy to help!

HAAS Servo Amplifier 4015P-B / 32-4015P-B

Technical Specifications

| Feature | Description |

|---|

| Device type | Brushless Servo Drive |

| Model | 4015P-B / 32-4015P-B |

| Rated current | approx. 30 A peak current |

| Power supply | approx. 320 V DC via machine DC bus |

| Cooling | Passive via rear heat sink |

| Control interface | 14-pin ribbon cable (signal) |

| Power connections | DC bus and motor phases |

| Communication | Direct connection to MOCON board |

| Application | Axis amplifier in HAAS CNC machines |

Typical Alarms and Causes

| Alarm code | Description | Possible cause |

|---|

| 103 / 104 / 105 | X, Y, Z Servo Error | Axis cannot follow commanded motion |

| 161 | Drive Fault | Internal fault in the amplifier |

| 162 | Axis Overcurrent | Overcurrent due to load or internal defect |

| 175 | Ground Fault | Ground fault inside the amplifier or motor circuit |

| 647 | Amplifier Overheat | Thermal overload or sensor issue |

Troubleshooting and Diagnostic Notes

| Check step | Description |

|---|

| Axis swap test | Swapping amplifiers between axes to isolate the fault |

| DC bus check | Verification of the 320 V DC via LED indication |

| Connectors | Inspection of the 14-pin ribbon cable |

| Phase measurement | Comparison of motor winding resistances |

| Safety measure | Observe a discharge time of at least 5–10 minutes |

Test Capabilities at Industrypart

| Test stage | Description |

|---|

| Electrical bench test | Control system simulation with full signal monitoring |

| Thermal test | Load testing under realistic operating conditions |

| Machine test | Operation in an original HAAS machine under load |

| Final inspection | Checklist-based release process |

Preventive Measures

| Measure | Benefit |

|---|

| Regular visual inspection | Early detection of thermal damage |

| Contact and connector inspection | Prevention of contact resistance issues |

| Cooling concept verification | Reduction of thermal stress |

| Timely refurbishment | Avoidance of complete failures |

Conclusion:

The repair of the HAAS Servo Amplifier 4015P-B once again demonstrates how important a structured repair process, real machine testing, and preventive measures are. Only in this way can it be ensured that a refurbished amplifier not only functions, but also operates reliably over the long term in everyday production use.