14.05.2025 by Viktor Siebert

Haas Servo Amplifier 30A (32-5550J / 93-32-5550J) – Repair, Technical Data and Troubleshooting

Repair Story & Our Experience

For over a year now, we have included the Haas Servo Amplifier 30A, part numbers 32-5550J and its successor 93-32-5550J, into our repair portfolio. Previously, we had exclusively repaired the Haas HP Vector Drives, despite having the test equipment available. Initially, we rejected the servo amplifiers as they often arrived pre-repaired or severely burnt out. After deciding to take these units on, we have experienced excellent results. We have developed effective repair procedures and now repair these modules reliably and according to high-quality standards. Each amplifier undergoes initial testing on a dedicated test bench, followed by a final stress-test in an actual Haas CNC machine to ensure full functionality under real-world conditions. We have documented this final testing process in a video.

These units have a very compact design yet deliver impressive performance. Due to their compact build, they are prone to overheating. Another common failure occurs due to voltage spikes from the Vector Drive, often resulting in noticeable damage with a loud bang. We recommend regular inspection of the electrical cabinet, ensuring all cooling fans operate smoothly and proactively servicing the Vector Drive at the first signs of trouble to prolong the lifespan of the servo modules.

To mentioned HAAS Drive: Haas Servo Amplifier 30A 32-5550J or 93-32-5550J

More details about our HAAS repair services can be found here:

HAAS drive Repair by Industrypart

📞 Feel free to contact us with any questions about your HAAS drive technology.

Our expert team is happy to help!

Device Description and Technical Data

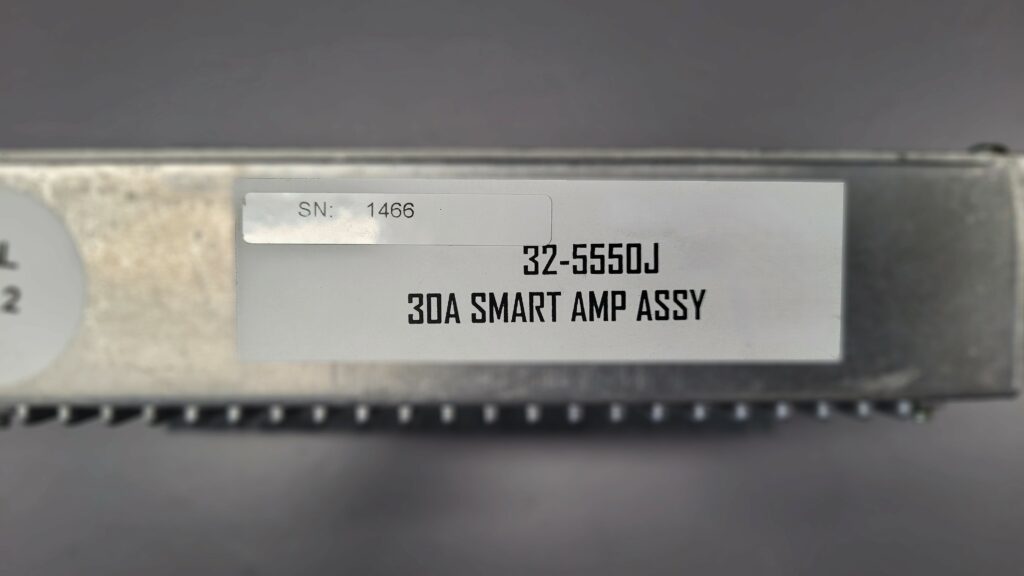

The Haas Servo Amplifier 30A is a smart servo amplifier module used in Haas CNC machines, specifically designed for axis drives. It provides up to 30 amps of phase current to the servo motors, powered by the approximately 320 V DC bus from the Vector Drive.

Key technical data are summarized in the following table:

| Parameter | Description/Value |

|---|

| Part Number | 32-5550J (old), 93-32-5550J (new) |

| Amplifier Type | Brushless Servo Amplifier (“Smart Amp”) |

| Rated Output Current | 30 A (Servo Motor) |

| Supply Voltage | 320 V DC bus from Vector Drive |

| Logic Supply Voltages | +5 V, ±12 V DC (from Maincon/Mocon PCB) |

| Status Indicators | Green LED (Power ON); Red LED (Fault) |

| Power Connections | HV+ / HV– input; 3-phase output (RED, WHT, BLK) |

| Cooling | External fan |

| Dimensions/Weight | Compact aluminum housing, approx. 0.6 kg |

Functionality

The Haas 30A servo amplifier is a PWM-based module that converts DC voltage from the Vector Drive into regulated AC currents for servo motors. Internally, transistor bridge circuits control the motor phases precisely. It continuously monitors current, temperature, and internal calibration status. The amplifier automatically shuts down and signals an alarm in case of faults such as short circuits, overcurrent, or overheating (90°C internally).

Two LED indicators (green for Power, red for Fault) clearly show operational status. Under normal conditions, the amplifier precisely controls servo motor currents. Any abnormal conditions trigger immediate protective shutdown and alarms, ensuring machine safety.

Alarm Messages and Troubleshooting

The following table summarizes common alarms, their causes, and solutions:

| Alarm Code & Message | Possible Cause | Recommended Solution |

|---|

| Alarm 993 – Amplifier Short Circuit | Shorted motor cable or amplifier defect | Check cables for contamination/damage; test amplifier and replace if shorted internally |

| Alarm 986 – Calibration Error | Internal calibration failure or cable issue | Inspect control cable connections; verify 320 V DC and ±12 V supplies |

| Alarm 992 – Amplifier Overcurrent | Axis mechanical blockage or motor short | Check axis for blockages or mechanical issues; test motor for short circuits |

| Alarm 994 – Amplifier Overload | Axis overload due to incorrect feeds or binding | Reduce feed rates, check cutting tools, mechanical lubrication, and ±12 V logic voltages |

| Alarm 991 – Amplifier Overtemperature | Cooling fan failure or high cabinet temperature | Ensure cooling fans operate properly; check cabinet temperature; inspect for sensor faults |

Troubleshooting involves systematic checking of mechanical and electrical components. Recommended procedures include multimeter checks for internal amplifier shorts, motor insulation tests, and logic voltage verification. Always follow safety guidelines, turning off machine power and allowing discharge of high voltages before handling amplifiers.