07.06.2025 by Viktor Siebert

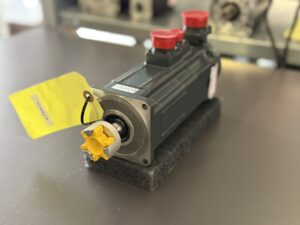

Mitsubishi HA33NCB-TSD5 AC Servo Motor with Encoder OSA104S and Brake UA-0.2-13 DC24V

We have just finished preparing this motor for shipment. The motor came from a machine manufacturer for evaluation—the customer wanted to know if we could reliably overhaul this motor type.

Initial Analysis and Endurance Testing

After the initial inspection, the motor ran without any interruptions. However, the bearings appeared slightly worn. We subjected the motor to a long-duration test under load to check whether faults would appear under specific conditions. Indeed, after repeated heating and cooling cycles at high speeds near the maximum RPM, the motor began to fail. Alarm 5A was triggered, and from that point on, the fault occurred at all speeds.

Root Cause: Encoder OSA104S

Alarm 5A indicates an encoder fault. We are familiar with this type of failure. In such cases, there are two options: either replace the encoder with a new one or repair the existing unit. We’ve been working with encoder repairs for many years. A new original Mitsubishi encoder costs around €2,700, so our repair service—at less than 30% of the new price—is a cost-effective alternative.

Overhaul and Repair Details

Following the diagnosis, we performed the following work on the motor:

- Disassembly and Visual Inspection: The motor was completely disassembled to inspect all components for wear and damage.

- Bearing Replacement: Both ball bearings were replaced with high-quality industrial bearings suitable for the motor’s speed range.

- Seal Replacement: Shaft seals were renewed to prevent future contamination by oil, dust, or coolant.

- Encoder Repair: The OSA104S encoder was opened, cleaned, and precisely recalibrated. Damaged components on the encoder disc and PCB were replaced.

- Stator and Rotor Testing: Windings were tested electrically (insulation, continuity, surge test), and the rotor was checked for runout.

- Brake Test: The holding brake UA-0.2-13 DC24V was tested—it was in like-new condition and only required cleaning.

- Protective Coating: Electrical contacts were treated and sensitive areas were coated with a special protective lacquer against moisture.

- Final Testing: Comprehensive load test using original drive unit MDS-C1-V2-0303 or 0505 with machine-specific parameters and thermal cycling.

Important Note on the Testing Procedure

A precise testing procedure is crucial for this motor type. The motor must be tested with the original drive and machine parameters; otherwise, many faults simply won’t be reproduced. This often happens when buying used motors or encoders online. Sellers may claim the motor was tested and even provide a video—but in most cases, the test was done using a basic MR-J2S series servo amplifier, which is a very superficial method. Only when the motor is tested using an MDS-C1-V2-0303 or -0505 do the actual faults appear.

Our Appeal

When purchasing, be sure to ask: How was the motor—and especially the encoder OSA104S—tested? And with which drive?

To mentioned Mitsubishi Motor: Mitsubishi HA33NCB-TSD5 AC Servo Motor

More details about our Mitsubishi repair services can be found here:

Mitsubishi motor Repair by Industrypart

📞 Feel free to contact us with any questions about your Mitsubishi drive technology.

Our expert team is happy to help!

Technical Datasheet – Mitsubishi HA33NCB-TSD5

| Parameter | Specification |

|---|

| Manufacturer | Mitsubishi Electric |

| Product Type | AC Servo Motor |

| Model | HA33NCB-TSD5 |

| Country of Origin | Japan |

| Power Output | 450 W |

| Rated Voltage | 159 V |

| Rated Current | 2.8 A |

| Phases | 3-phase AC |

| Rated Speed | 3000 rpm |

| Protection Class | IP65 |

| Brake | UA-0.2-13, DC 24V |

| Encoder | OSA104S (incremental or absolute depending on variant) |

Common Error and Alarm Messages (e.g. on MDS-C1-V2 Drives)

| Alarm Code | Meaning | Possible Cause | Solution / Action |

|---|

| AL.20 | Overspeed | Load too light or feedback signal error | Check mechanical load, inspect encoder signal quality |

| AL.04 | Overcurrent | Motor short circuit or incorrect wiring | Perform insulation test, verify wiring and terminals |

| AL.30 | Brake not releasing | No brake power or mechanical fault | Check 24V supply, manually test brake mechanism |

| AL.52 | Positioning error | Unstable feedback, axis losing position | Check encoder signal, verify control parameters |

Troubleshooting & Self-Check Tips for Customers

Customers with basic technical knowledge can perform the following checks before sending in the motor for repair:

Visual Checks & Basic Measures

- Check all connectors: Ensure encoder, brake, and power connectors are properly seated and not loose.

- Look for damaged cables: Focus on bends, crushed points, or insulation cracks – especially on encoder and brake wires.

- Brake test: Do you hear a click at power-up? If not, measure the 24 V brake voltage.

- Thermal behavior: Does the fault occur only after warm-up or prolonged operation?

Electrical Tests (if equipment available)

- Insulation resistance test (500 V megger): Resistance between any phase and ground should be >10 MΩ.

- Encoder signal test: Use an oscilloscope or diagnostic software to verify clean, stable signal output.

- Brake resistance measurement: Resistance should not be open; expect approx. 50–100 Ω depending on version.

Extra Tips

- Avoid incorrect test setups: The OSA104S encoder must be tested with original drives and correct machine parameters—basic tests on universal drives are often misleading.

- Be cautious with online purchases: Motors labeled as “tested” are often only checked with minimal effort. Always ask how and with what equipment the test was performed.

- Heat is a critical factor: Many encoder faults appear only during thermal cycles—this is why extended load tests are essential.

Conclusion

The Mitsubishi HA33NCB-TSD5 is a compact, durable servo motor. The most common issues are related to bearing wear or encoder failure. A professional repair with proper diagnostic tools and original drives is highly recommended. However, customers can perform basic checks and rule out common issues before sending in the motor.