04.12.2025 by Viktor Siebert

Repair of a Fanuc Alpha 22 AC Spindle Motor A06B-0859-B100 with defective fan and encoder error

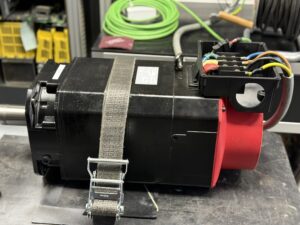

The Fanuc Alpha 22 AC spindle motor A06B-0859-B100 arrived in our workshop in heavily contaminated condition. The customer reported that the machine repeatedly produced spindle alarm 31 as well as sporadic encoder errors. In addition, the spindle ran unevenly at low speed. During initial inspection significant contamination from coolant, dust and metal particles was visible. This is typical for older machining centers operating under high thermal load. When turning the shaft manually it became obvious that the fan was completely blocked. The fan blades were stuck due to dried coolant and the motor most likely overheated after only a few minutes of operation.

After completely disassembling the motor the suspicion was confirmed. The fan type A90L-0001-0444/RS was mechanically clogged, the bearings were damaged and the fan rotor could no longer rotate freely. In addition, the encoder A20B-2002-0300/02A showed unstable feedback signals. This indicated internal corrosion caused by long term exposure to oil mist and coolant vapor. The oscilloscope showed fluctuating commutation signals which explained the poor running behavior in the machine.

The motor was completely cleaned. The stator slots were flushed and treated with solvent. Afterwards the windings were tested using a professional 1 kV insulation test. All values stayed within the allowed range which ruled out winding damage. The rotor was removed, cleaned and checked for runout. No mechanical defects were found.

The encoder was replaced with an original module. Precise mechanical alignment was performed. The encoder disk was adjusted using an internal reference to ensure that the commutation signals match the rotor position exactly. The new fan A90L-0001-0444/RS was installed and electrically tested. All power and signal connectors were cleaned, resealed and installed.

In the next step the motor was transferred to our Fanuc test bench. There it was operated together with a spindle amplifier A06B-6088-H226#H500. After encoder initialization the motor started smoothly for the first time. Multiple test cycles from 100 to 6000 rpm were executed. All relevant parameters such as current consumption, temperature, encoder signal quality and vibration behavior were monitored. Special attention was given to the alarms from the Fanuc manual, especially alarm 31 and alarm 19. Throughout the 90 minute test phase no errors occurred.

The motor ran smoothly with low vibration and all thermal values remained stable. The repair was successfully completed and the motor could be returned to the customer. Due to preventive replacement of the critical components such as fan and encoder significantly longer operating life without unexpected failures is expected.

Preventive Measures for the Customer

- Replace fan annually

- Check encoder and connectors for oil mist

- Clean motor regularly

- Perform insulation test every 12 months

- Document vibration values

- Inspect power cables

Conclusion

A blocked fan and a damaged encoder are typical failure sources in Fanuc spindle motors. Through complete overhaul, precise adjustment and thorough testing the functionality was fully restored. Preventive maintenance significantly increases service life.

To mentioned Fanuc Drive: Fanuc Alpha 22 AC Spindle Motor A06B-0859-B100

Menioned Drive: Fanuc Spindle Amplifier A06B-6088-H226#H500

More details about our Fanuc repair services can be found here:

Fanuc drive Repair by Industrypart

📞 Feel free to contact us with any questions about your Fanuc drive technology.

Our expert team is happy to help!

Device Specifications:

| Feature | Value |

|---|

| Model | Fanuc Alpha 22 AC Spindle Motor A06B-0859-B100 |

| Power | approx. 22 kW |

| Voltage | 3 phase, 200 to 230 V AC |

| Rated speed | approx. 1500 to 6000 rpm depending on machine |

| Encoder | A20B-2002-0300/02A |

| Encoder type | Serial incremental encoder, manufacturer Minebea |

| Fan | A90L-0001-0444/RS, RT6925-0220W-B30R-S03 |

| Cooling | Axial fan, external |

| Protection class | IP protected depending on machine |

| Compatible spindle drive | Fanuc Spindle Amplifier A06B-6088-H226#H500 |

| Manual reference | Fanuc spindle alarm section, pages 86 to 97 |

Operating Environment and Compatible Equipment

The spindle motor A06B-0859-B100 is commonly used in vertical and horizontal machining centers such as:

- Mori Seiki

- Victor

- Doosan

- Chiron

- Mazak with Fanuc 16, 18 or 21 series

It is compatible with:

- Fanuc spindle amplifier Alpha series

- Fanuc CNC controls 0i, 16i, 18i, 21i

- Alpha encoder systems with serial feedback

Typical environments include:

- High thermal load

- Metal chips, oil mist and coolant

- Continuous operation with high load profile

Functional Description

The Fanuc Alpha 22 AC spindle motor provides precise and dynamic spindle control. It transmits speed and torque through a closed control loop involving:

- Spindle amplifier

- CNC control

- Encoder feedback

The encoder A20B-2002-0300/02A supplies high resolution position and speed signals required for commutation and speed control. The customer installed fan A90L-0001-0444/RS ensures continuous cooling during operation. A fan failure causes rapid overheating and an encoder failure results in an immediate stop.

The spindle drive A06B-6088-H226#H500 monitors overload, overspeed, encoder communication, overtemperature, overcurrent and DC bus voltage and generates the typical Fanuc spindle alarms.

Alarm Messages and Troubleshooting

| Code | Description | Cause | Solution |

|---|

| 01 | Overcurrent | Output overcurrent | Check motor, check cable |

| 02 | Overvoltage | DC bus too high | Check mains, check braking resistor |

| 03 | Overheat | Overtemperature | Check cooling, replace fan |

| 05 | Spindle drive fault | Power module fault | Check drive |

| 12 | Speed command fault | Speed command invalid | Check parameters |

| 19 | Overspeed | Spindle rotates too fast | Check encoder |

| 31 | Spindle alarm 31 | Rotor does not start or runs poorly | Check motor and encoder |

| 32 | Speed deviation | Actual and commanded speed differ | Check load and encoder |

| 40 | Regeneration error | Regeneration overload | Check regenerative resistor |

| 50 | Input power fault | Input problem | Check power phases |

Components

| Component | Type / Code | Function | Notes |

|---|

| Encoder | A20B-2002-0300/02A | Position and speed feedback | Sensitive to contamination and heat |

| Fan | A90L-0001-0444/RS | Cooling | Often blocked by oil or coolant |

| Fan motor | RT6925-0220W-B30R-S03 | Drives the fan | Check bearings |

| Stator | — | Generates magnetic field | Insulation test required |

| Rotor | — | Rotating unit | Check balance |

| Connectors | Fanuc Alpha | Power and signal interfaces | Often corroded or contaminated |