05.07.2025 by Viktor Siebert

Berger Lahr Stepper Drive: Should We Keep Repairing Them?

A sincere question to our customers and partners.

The Situation

This is one of those requests that catch you by surprise and yet feel strangely familiar:

A machine supplier reached out and asked us to repair several Berger Lahr Stepper Drive.

To be specific: D500, D550, D650, and D900 all devices that have been discontinued for years.

We ourselves officially discontinued service for them about a year ago.

And yet we didn’t say no.

Why?

Because we can. And because we understand them.

The Story Behind It

We’ve been repairing these drives for well over a decade with structure, experience, and most importantly: success.

We have test benches, spare parts, know-how, and a long list of documented repairs.

Our customers have never cared about the production date only about the result.

And so, we accepted the request again.

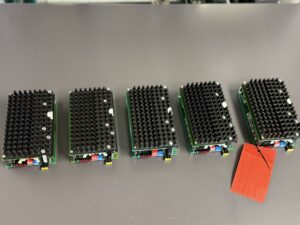

The outcome? Multiple units, fully overhauled, tested, warrantied and back in action.

And now we’re asking ourselves an honest question:

Should we officially continue offering repairs for these drives?

Why ask this at all?

Looking at the market, it’s clear: most manufacturers have understandably stopped supporting old systems.

The Berger Lahr division was absorbed by Schneider Electric, and the product lines were either discontinued or restructured.

There is no official support anymore.

But demand still exists.

And so do we.

However:

- Does it make sense to continue servicing systems that officially no longer exist?

- How long can we keep spare parts in stock without it becoming a financial burden?

- And most importantly: How many customers actually still operate these drives and would want them repaired?

Here’s how we see it:

✅ Technically no problem. We have the tools, the knowledge, and the setup.

✅ Experience plenty. These drives are like old friends to us.

✅ Economically it could make sense… if the need is real.

❌ But: we don’t want to offer a service that no one really needs anymore.

❌ And we don’t want to promise something if spare parts become unavailable tomorrow.

So now we ask you:

Are you still using Berger Lahr Stepper Drive in your machines?

Would you consider professional repair as a real option when problems arise?

Would you appreciate having a reliable service partner for these discontinued models?

Our Position

We are ready.

If the demand is there, we’ll make it official.

We’ll update our website, share our expertise, and continue to provide reliable repairs when no one else can.

But we don’t want to offer a service just to keep it on paper.

That’s why your opinion matters.

What You Can Do

Send us a message.

Or just say: “Yes, please continue!”

Because maybe your machines depend on a service like this.

And it would be a shame to let it go just because no one spoke up.

Additional Information: Berger Lahr D500, D550, D650, D900

📞 Please feel free to contact us if you have any questions regarding your Berger Lahr drive technology. Our experienced team is always available to assist you.

Technical Information: Berger Lahr D550 Stepper Drive Card

The Berger Lahr D550 power control card is designed to operate 5-phase stepper motors without rotational feedback. It serves as a compact and efficient interface for converting digital control signals into the precise current required to drive stepper motors in industrial applications.

General Functionality

The D550 receives standard control signals such as pulse (step), direction, enable (gate), and boost/PWM. It generates constant current outputs to power a connected 5-phase stepper motor. The current regulation is achieved through pulse-width modulation (PWM) with a switching frequency of approximately 25 kHz

Technical Specifications

| Parameter | Specification |

|---|

| Operating voltage | 35–70 VDC |

| Idle current draw | < 10% |

| Max. phase current | 6 A |

| Phase current adjustable | 0.55 A to 2.8 A |

| PWM frequency | ~25 kHz |

| Boost function | Yes (up to 1.2 × nominal current) |

| Logic level (D550.00) | 24 V logic (20–30 V = logic high) |

| Logic level (D550.01) | 5 V logic (2.5–5.25 V = logic high) |

| Galvanic isolation | On all inputs |

| Weight | < 900 g |

| Cooling | Passive (external airflow recommended) |

Control Inputs

Front panel indicators provide real-time feedback:

- LED 1 (green): Power ON / Ready

- LED 2 (red): Short-circuit or overload

- LED 3 (red): Overtemperature

- LED 4 (red): Undervoltage / Overvoltage

- LED 5 (red): Phase interruption

- LED 6 (red): Status (e.g. boost mode or PWM active)

Connector and Pinout

Connector type: 32-pin DIN 41612 (type D)

Key signals: Step, direction, enable, boost, motor outputs W1–W5

Error Diagnosis and Troubleshooting

| Error | Possible Cause | Recommended Action |

|---|

| No motor movement | Missing or incorrect pulse signal | Check controller and wiring |

| Short-circuit / overload | Cable fault, defective motor | Inspect and replace as needed |

| Overtemperature | Poor ventilation, high ambient temp | Improve cooling, reduce load |

| Over/undervoltage | Power supply instability | Verify and stabilize PSU |

| Phase interruption | Disconnected or damaged windings | Check motor and connections |

Compatible Motors

The D550 is compatible with a range of Berger Lahr 5-phase stepper motors. Some examples:

| Motor Type | Max. Phase Current | Recommended DIP Setting |

|---|

| RDM 566/50 | 0.75 A | Position 1 |

| RDM 596/50 | 1.5 A | Position 4 |

| RDM 599/50 | 2.3 A | Position 6 |

| RDM 596/70 | 2.8 A | Position E |